High strength aluminum alloy quincunx deep blind hole piece extrusion molding technique

A high-strength, aluminum alloy technology, applied in the extrusion process of high-strength aluminum alloy plum blossom-shaped deep blind hole parts, to achieve high precision, reduce production costs, and reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

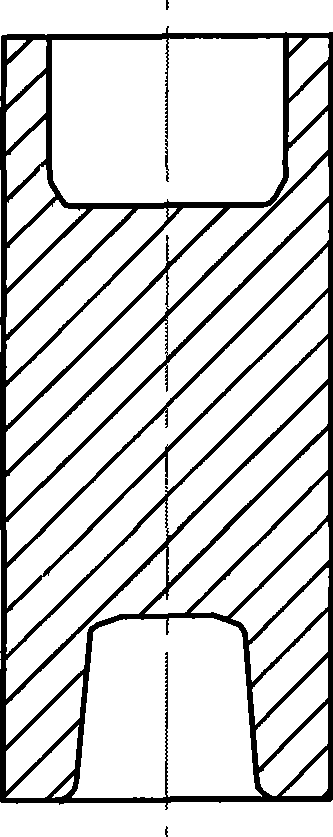

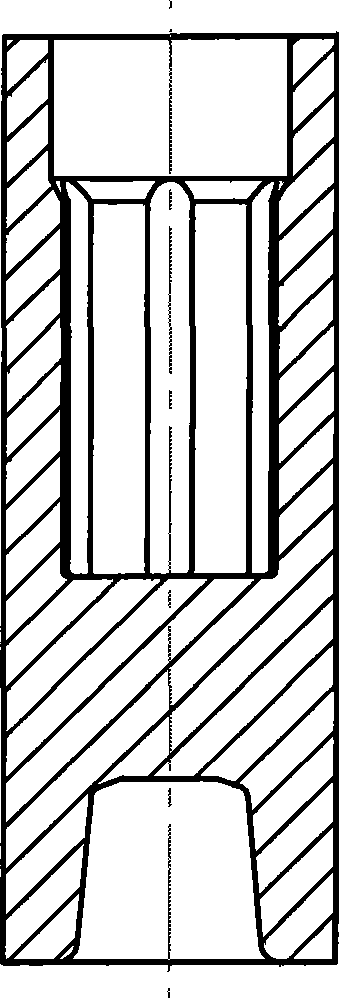

[0025] Such as Figure 1 ~ Figure 4 Shown, the concrete process sequence step of the present invention is as follows:

[0026] (1) On the CK6136 lathe, cut the bar stock with a diameter of φ32 into a section with a length of 61.5mm;

[0027] (2) Put the saving material into the model CS101 box-type electric furnace to heat, and keep it warm for 3 hours after the temperature reaches 380°C±10°C, and cool to room temperature with the furnace;

[0028] (3) After cleaning the saving material with hot water, put it into a sodium hydroxide solution (the solution concentration is NaOH40-60g / L, the solution temperature is 60°C~70°C) for oxidation treatment for 10min~15min, take it out and dry it After drying, evenly coat the material with zinc stearate powder;

[0029] (4) Composite extrusion: Put the material into the extrusion die for composite extrusion, extrude the upper and lower round holes and regularize the shape;

[0030] (5) After cleaning the workpiece with hot water, dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com