Casting system of wind power generator planet carrier

A technology for wind turbines and pouring systems, which is applied to equipment for feeding molten metal into casting molds, metal processing equipment, casting equipment, etc., can solve the problem of scrapping the planetary frame of wind turbines, increasing the cost of manufacturers, and prone to scum. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

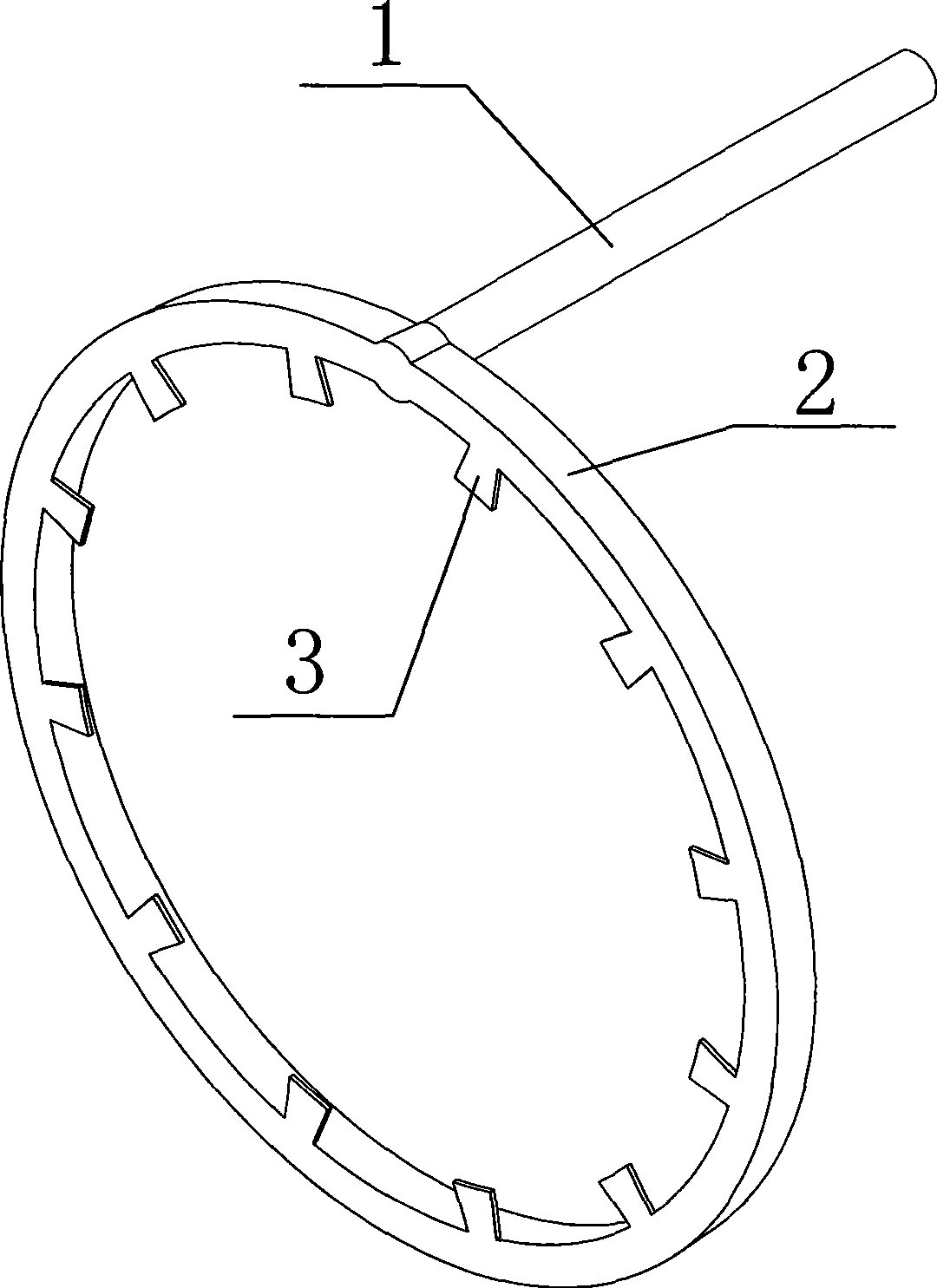

[0018] like figure 1 Shown is a gating system structure of a prior art wind turbine planetary frame, which includes the original sprue 1, the original annular cross gate 2 and a plurality of original ingates 3, and it has no filtering part; The outlet of the original straight gate 1 is connected with the entrance of the original annular runner gate 2; the original annular runner gate 2 is provided with multiple outlets, and these outlets are evenly distributed in the original annular runner gate 2 On the circumference; the outlet of the original annular runner 2 corresponds to the inner gate 3 one by one, and the outlet of the original annular runner 2 communicates with the entrance of the corresponding inner gate 3; the inner gate The outlet of port 3 communicates with the iron inlet of the cast-shaped spoke plate of the planetary frame of the wind-driven generator.

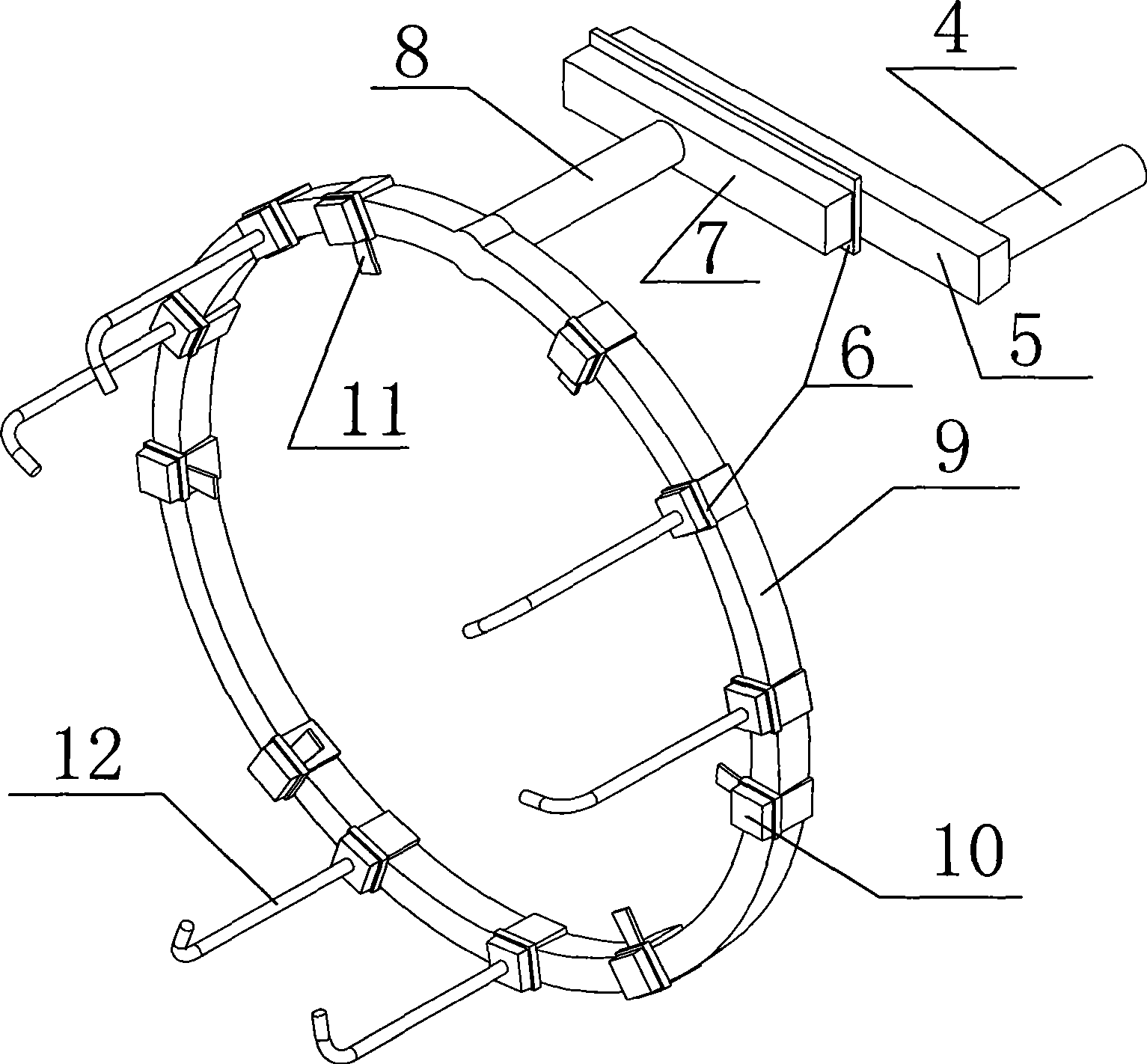

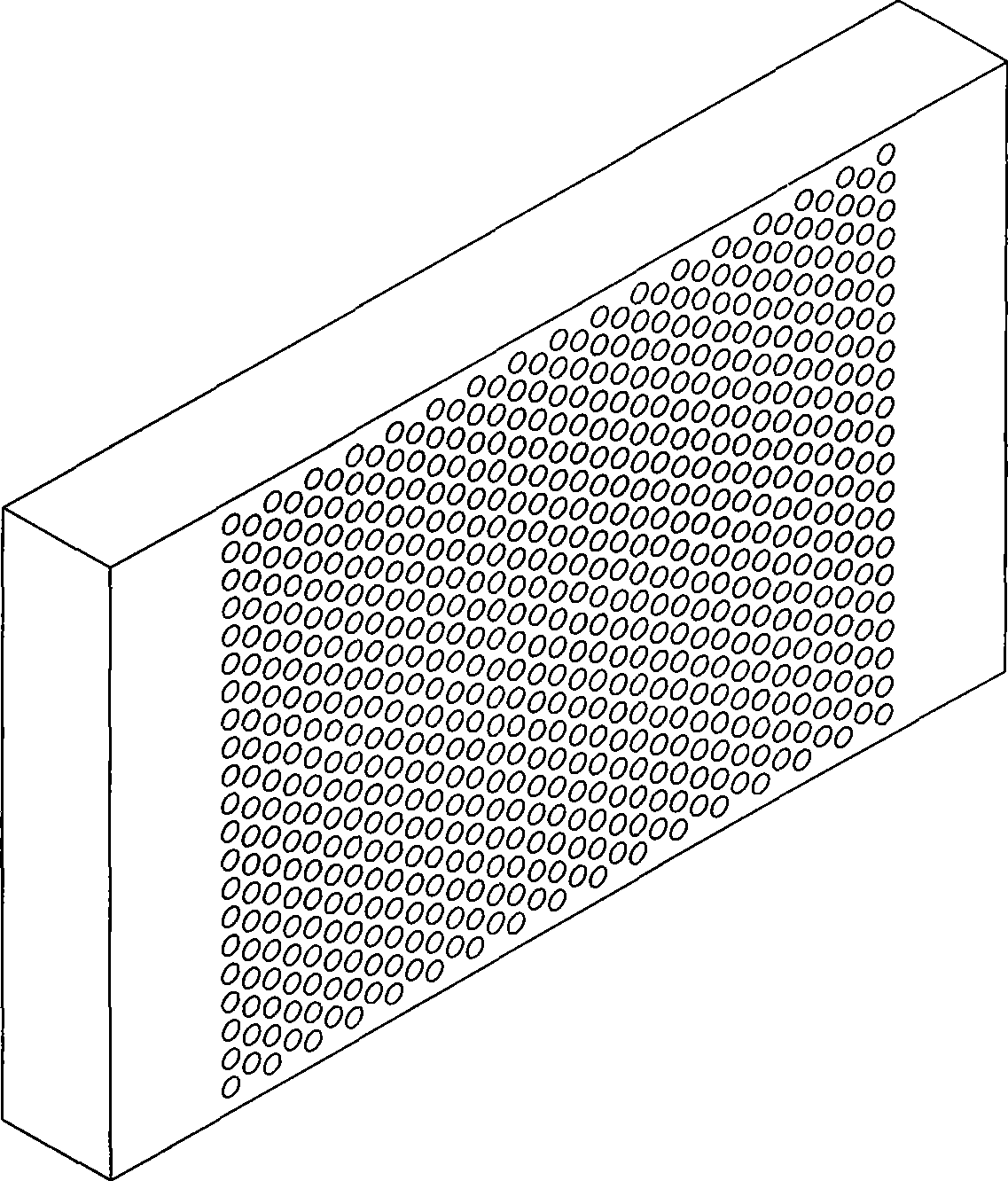

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com