Combined optical film sheet and method for manufacturing same

An optical film and manufacturing method technology, applied in optics, nonlinear optics, lighting devices, etc., can solve the problems of increasing the process and time, increasing the number of optical components, increasing the manufacturing cost, etc., so as to reduce the production cost, reduce the number, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

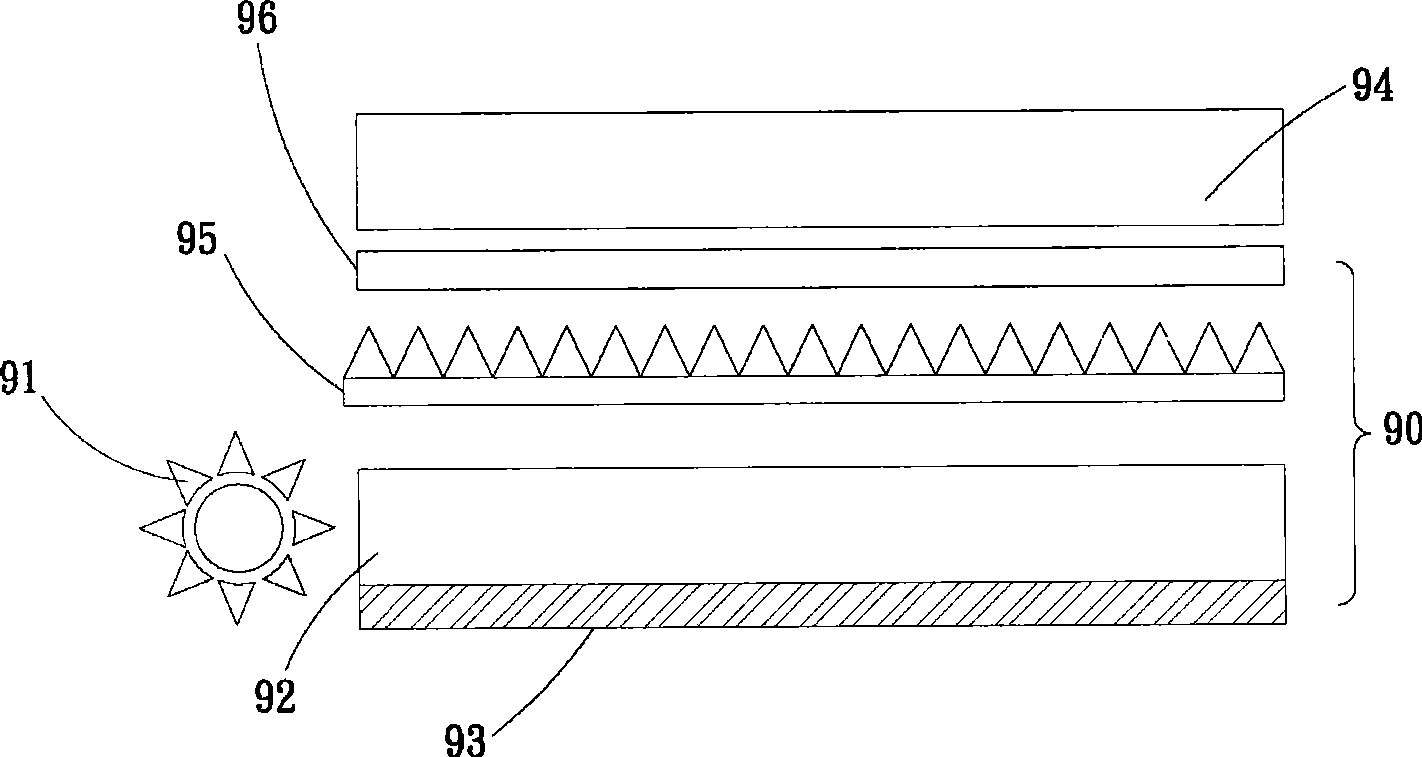

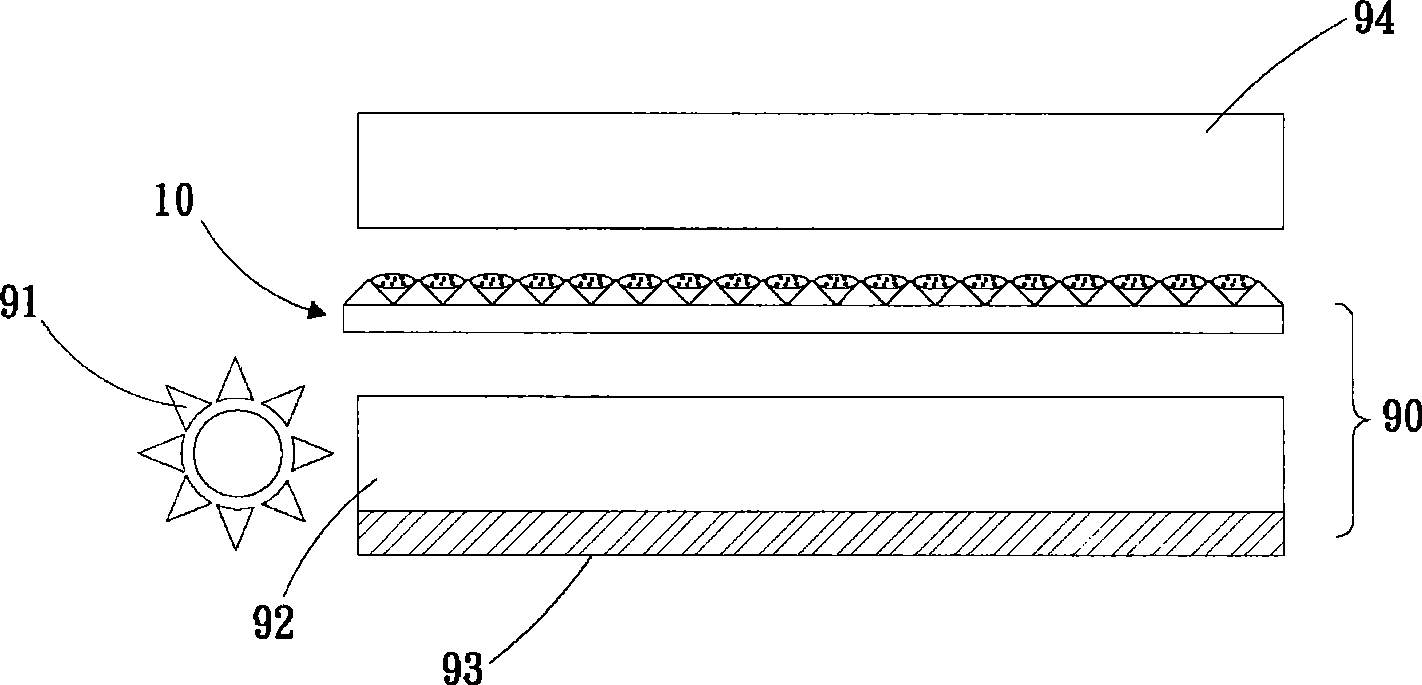

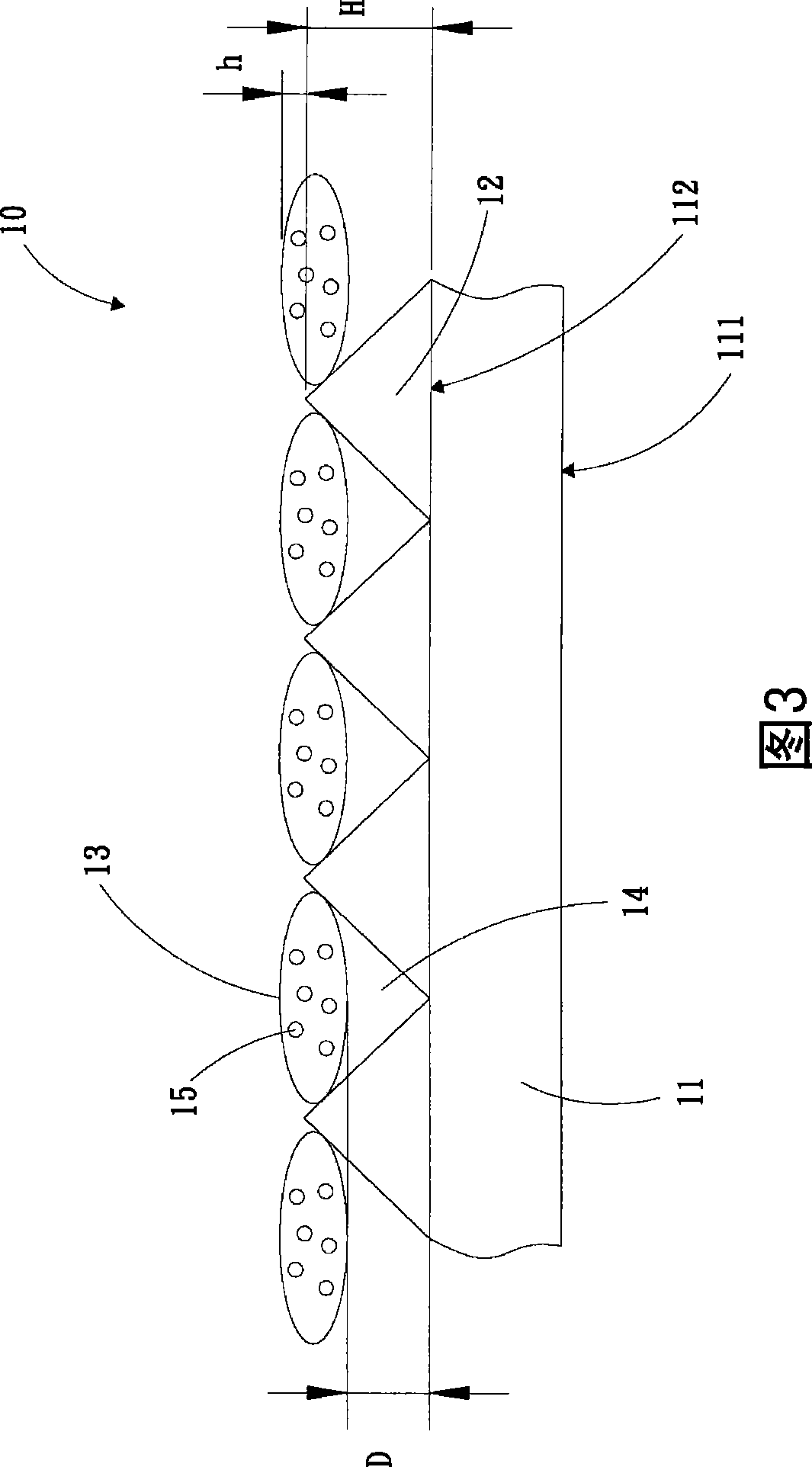

[0042] see figure 2 3 , which is an embodiment of the display device and the composite optical film of the present invention, discloses a backlight module 90 and the composite optical film 10 applied to the backlight module 90 . The backlight module 90 includes a backlight 91 , a light guide plate 92 , a reflection sheet 93 , and a composite optical film 10 . The backlight module 90 is used to provide backlight to a display panel 94 , wherein the composite optical film 10 is used to achieve the effects of diffusion and light collection, so as to enhance the front intensity of the backlight. The composite optical film 10 includes a flexible substrate 11 , a plurality of protruding light-collecting prisms 12 and a plurality of transparent micelles 13 .

[0043] The flexible substrate 11 is made of light-transmitting materials, such as polystyrene (PS), polyvinyl chloride (PVC) or polymethyl methacrylate (PMMA), for allowing light to pass through and can be bent , deformation....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap