Processing method for roll aluminium electrolysis capacitor insulation sheet rubber

A technology of aluminum electrolytic capacitors and insulating rubber sheets, which is used in capacitors, capacitor manufacturing, capacitor parts and other directions, can solve the problems of short product life, high price, increase storage material preparation and storage costs, etc. The effect of lowering the price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment, the specific embodiment of the present invention is described in further detail:

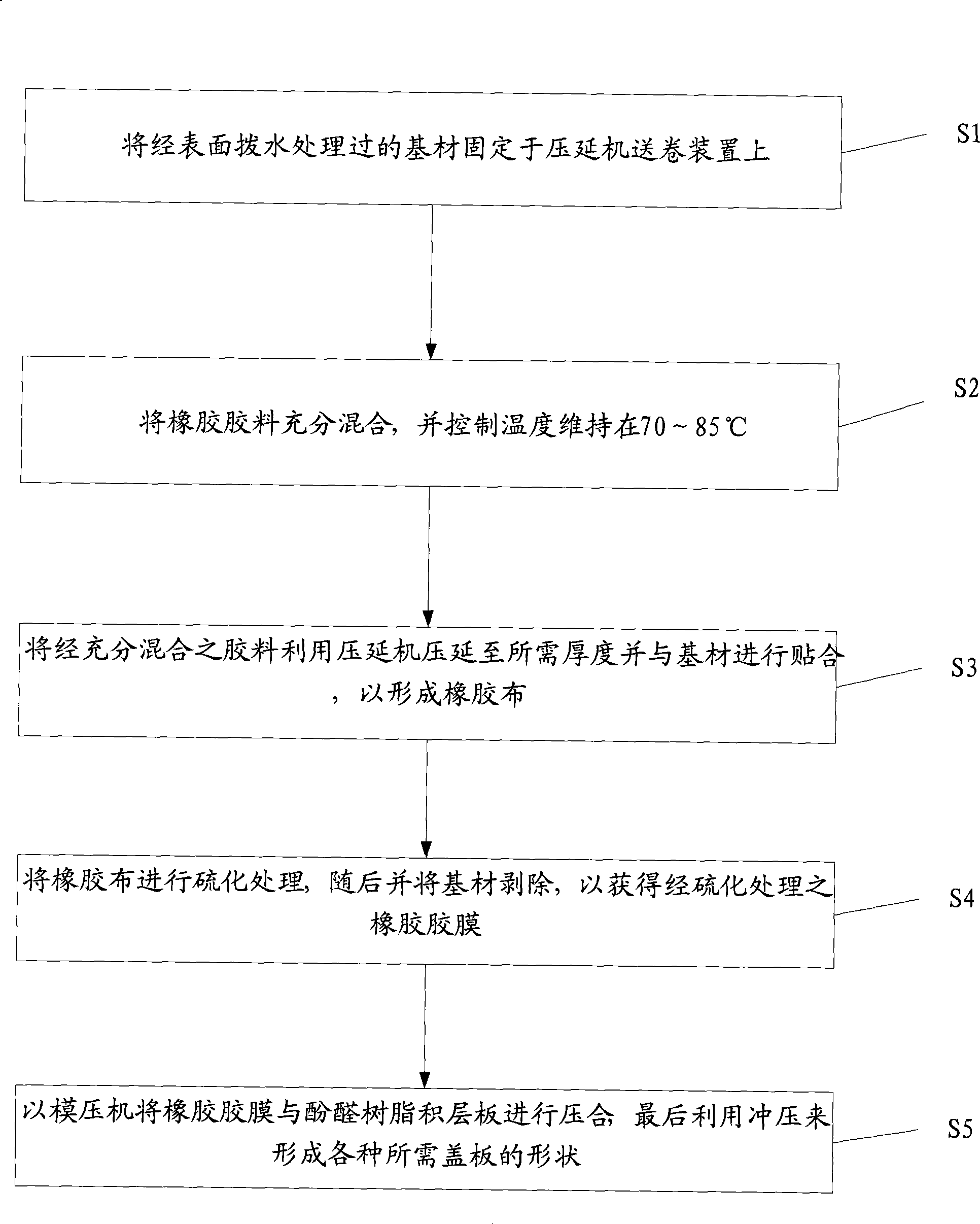

[0011] see figure 1 , which is a flowchart of the present invention. As shown in the figure, first, as described in step S1, the base material that has undergone surface water-repellent treatment, such as flat woven fabric, is fixed on the rolling device of the calender; The rubber compound after refining is fully mixed with rollers, such as two rollers (coarse wheel and fine wheel), and at this time, the temperature is controlled to maintain at 70-85°C; as described in step S3, the fully mixed rubber compound, Send it into the calender with the conveyor belt. At this time, set the roller temperature of the calender to be controlled between 75 and 90°C to roll the rubber material to the rubber film of the required thickness, and use the adhesiveness of the rubber film itself and the The base material on the roll feeding devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com