Methods of extracting rna

A ribonucleic acid and cell technology, applied in the field of RNA extraction, can solve the problems of complicated RNA application, troublesome multi-step characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

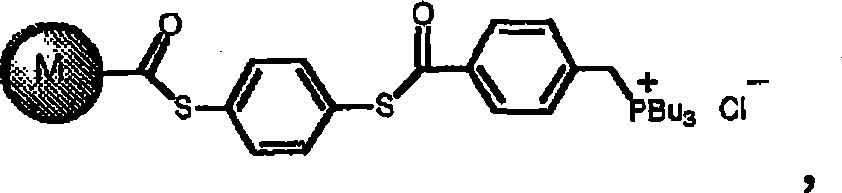

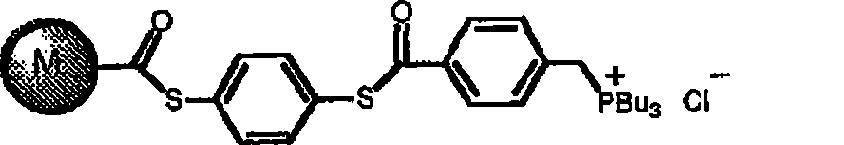

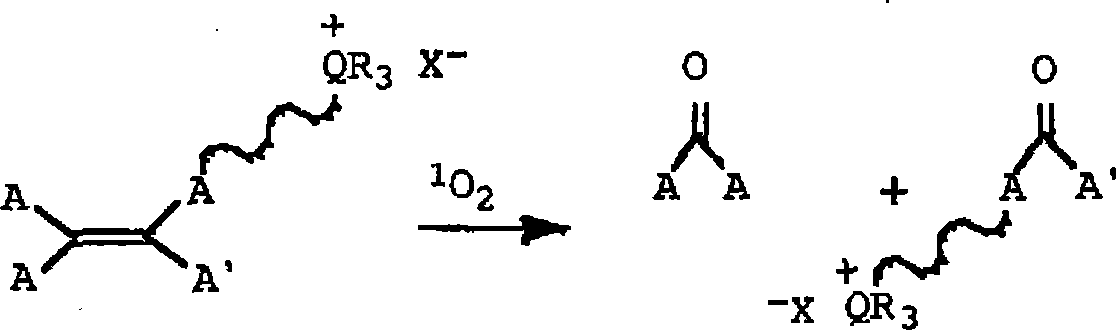

[0088] Example 1. Solid phase materials for isolating RNA. Synthesis of magnetic particles functionalized with tributylphosphonium NAB groups and cleavable arylthioester linkages.

[0089]

[0090] a) Prepare the magnet. Argon gas was bubbled into 3 liters of type I water in a 5 liter bottle over 1 hour. Add concentrated NH under argon 4 OH (28%, 180 mL). Add 50 mL of 2M FeCl in 1M HCl via the dropping funnel over about 1 hour 2 and 200 mL of 1M FeCl in 1M HCl 3mixture. The solids were collected in two flasks by the following procedure, poured in 500-600 mL portions each into the flask with the external disk magnet, and decanted the supernatant. The solid was washed by sonication in 500-600 ml of Type I water followed by attraction to a magnet and decanting of the supernatant. The process was repeated until the pH of the supernatant was approximately 8.5. The contents of the two vials were combined so that the magnets held a total volume of approximately 500 ml.

...

Embodiment 2

[0098] Example 2. Larger particle size solid phase material. Synthesis of magnetic particles functionalized with tributylphosphonium NAB groups and cleavable arylthioester linkages.

[0099]

[0100] a) Add 3-methylaminopropyltrimethoxysilane (149.8 g) into a 500 ml flask and fill it with argon. After placing the flask in an ice bath, acryloyloxytrimethylsilane (119.6 g) was slowly added with a syringe. The reaction was stirred for 5 minutes, the ice bath was removed and stirring was continued for 2 hours. The product was used without further purification.

[0101] b) Dilute 5.0 grams of a commercial magnet (Strem Cat. No. 93-2616, 1-5 microns) with 140 milliliters of Type I water and 1.25 liters of ethanol. After 30-45 minutes add concentrated NH 4 OH (28%, 170 mL). 1.5 g of silyl ester from step b) and 13.5 g of Si(OEt) 4 The ethanol solution was added to the reaction in three portions over a period of 90 minutes. A solution of 3.75 g of the silyl ester compound i...

Embodiment 3

[0107] Example 3 .Synthesis of functionalized magnetic polymer

[0108]

[0109] An aliquot of beads (Dynal magnetic COOH beads, Lot G36710) containing 25 mg of solids was decanted with the aid of a magnetic force. Then with 3 x 1 ml water and 3 x 1 ml CH 3 The beads were washed with CN and then dried for 4 hours. The beads were suspended in 1 mL CH to which 28.8 mg EDC had been added. 2 Cl 2 , shake for 30 minutes. A solution of 1,4-benzenedithiol (30 mg) was added to the mixture. The tubes were sonicated for 1 min and shaken overnight. Remove the supernatant, relying on magnetic force with 4 x 1 ml of CH 2 Cl 2 , 1 ml 1:1 methanol:CH 2 Cl 2 , 4 x 1 mL methanol and 4 x 1 mL CH 2 Cl 2 The beads are washed.

[0110] The beads were suspended in 1 ml of CH to which 140 μl of tributylphosphine had been added. 2 Cl 2 middle. The reaction mixture was vortexed for 1 min and shaken for a total of 3 days. Pour off the solvent by holding on to the magnet. Rely on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com