Split type multi-roller multi-component high-gradient vibration magnetic separator in permanent magnetism

A high-gradient, magnetic separator technology, applied in high-gradient magnetic separators and other directions, can solve the problems of excessive consumption of materials, increase production pressure in downstream processes, blockage, etc., and achieve the effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

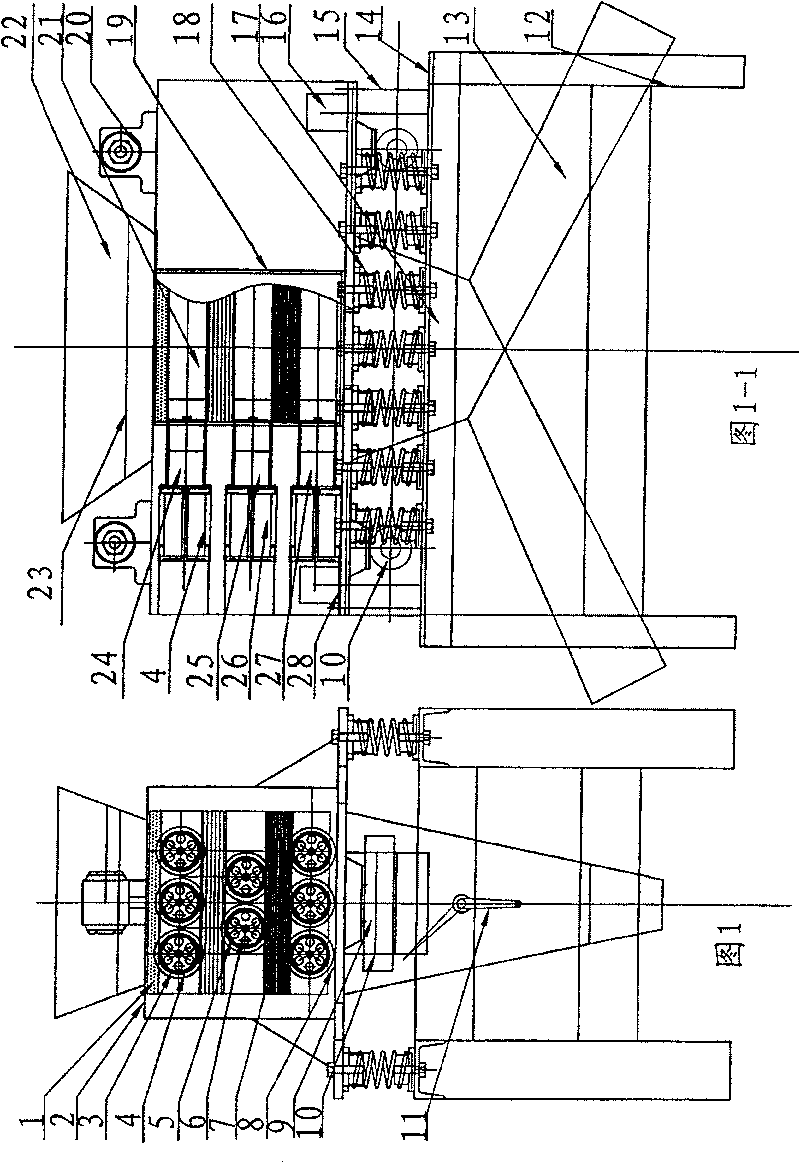

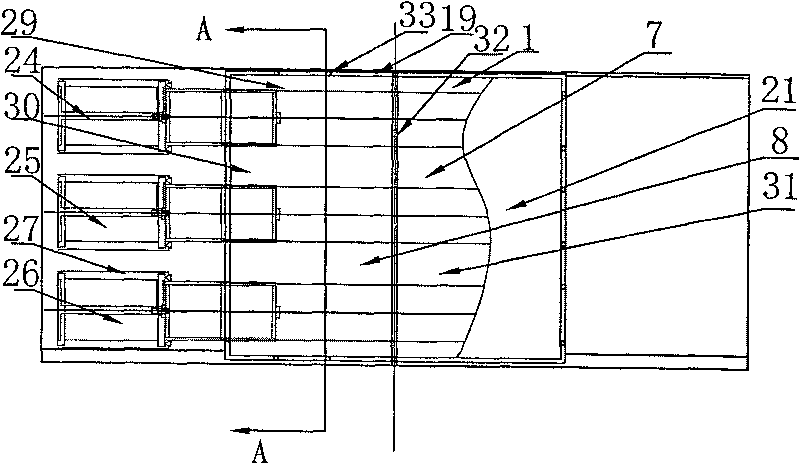

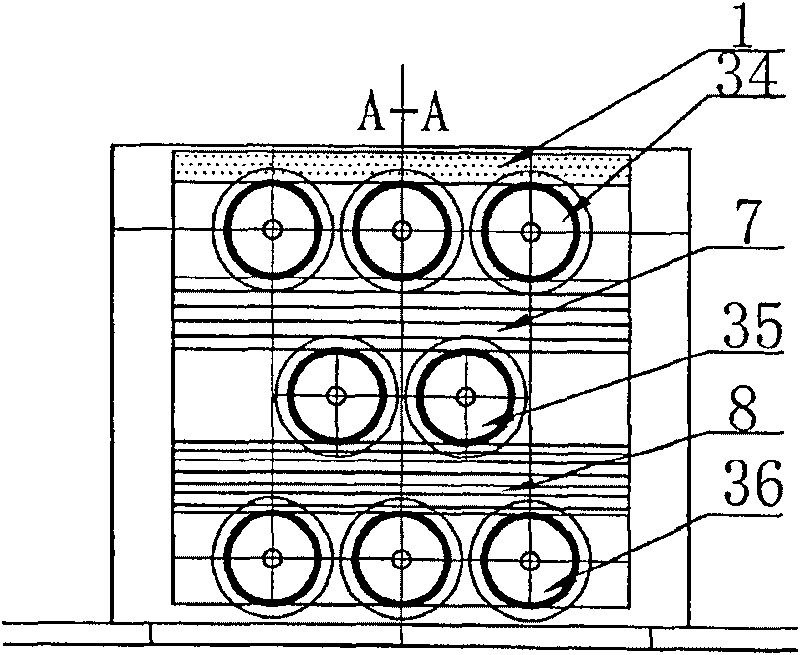

[0048] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0049] Such as figure 1 , Picture 1-1 As shown, the high-gradient magnetic separator of the present invention comprises frame 12, is arranged on the body (magnetic separation box body) 2 that is made of upper and lower cover and side cover above frame 12, and body 2 passes vibration-damping spring group 18 It is connected with the frame 12, and then installed on the top of the frame 12 by bolts, and the cylinder installation area 9 and the pneumatic control group interface 14 of the air circuit 5 of the cylinder 4 are arranged on the side of the upper end of the frame 12 and the lower end of the body 2; A pneumatic vibrator 20 and a mechanical vibrator 10 are respectively installed on the upper and lower parts of the body 2, a feeding funnel 22 is provided on the upper part of the body, and a screen 23 is set up on the neck of the funnel to remove the bulk in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com