Cycle frame structure of pedal motorcycle

A technology of frame structure and motorcycle, which is applied to motorcycles, bicycle frames, motor vehicles and other directions, can solve the problems of high processing difficulty, small rigidity strengthening effect of the frame, and increased processing procedures, so as to reduce the difficulty of the manufacturing process and enhance the Strength and rigidity, the effect of satisfying rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

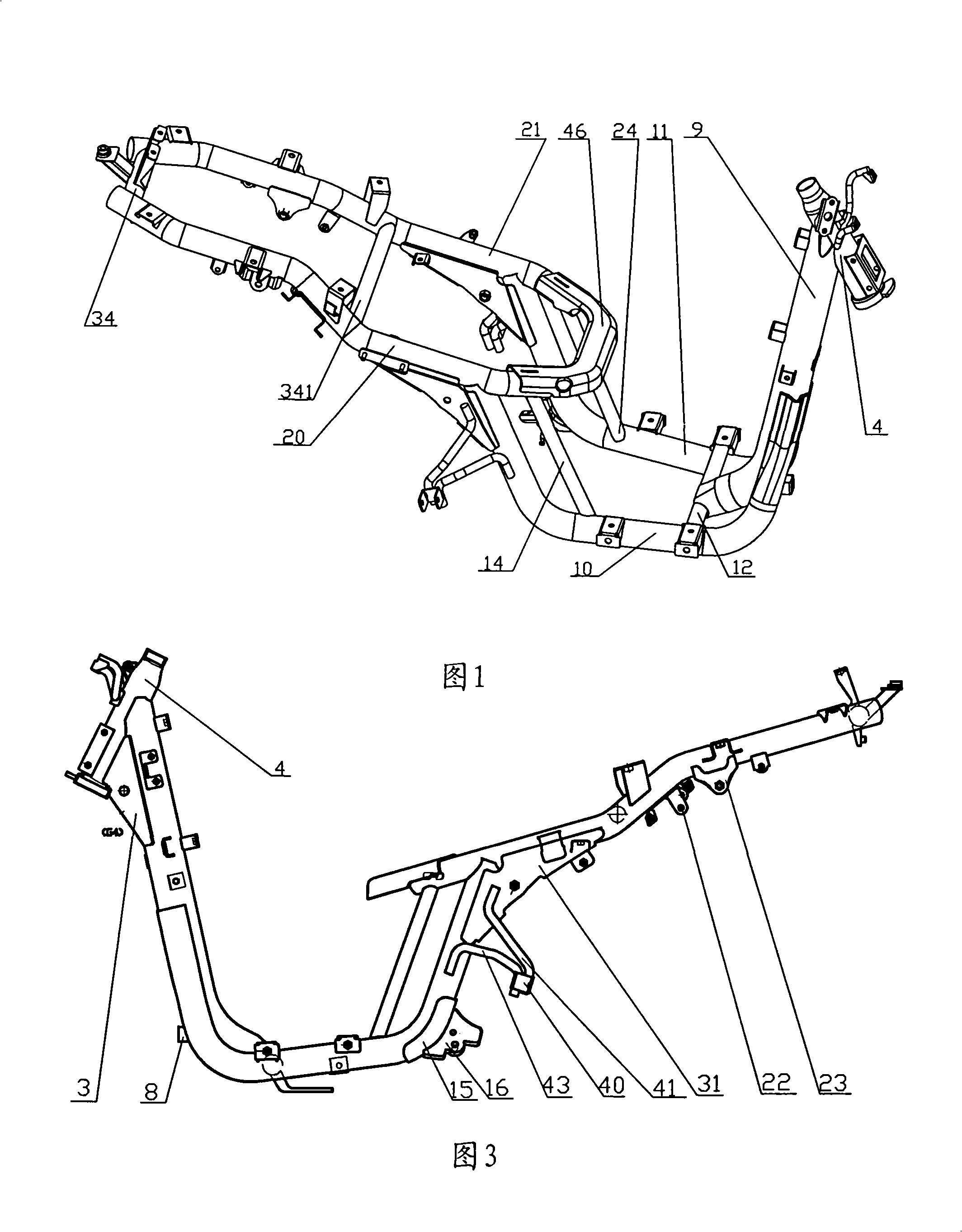

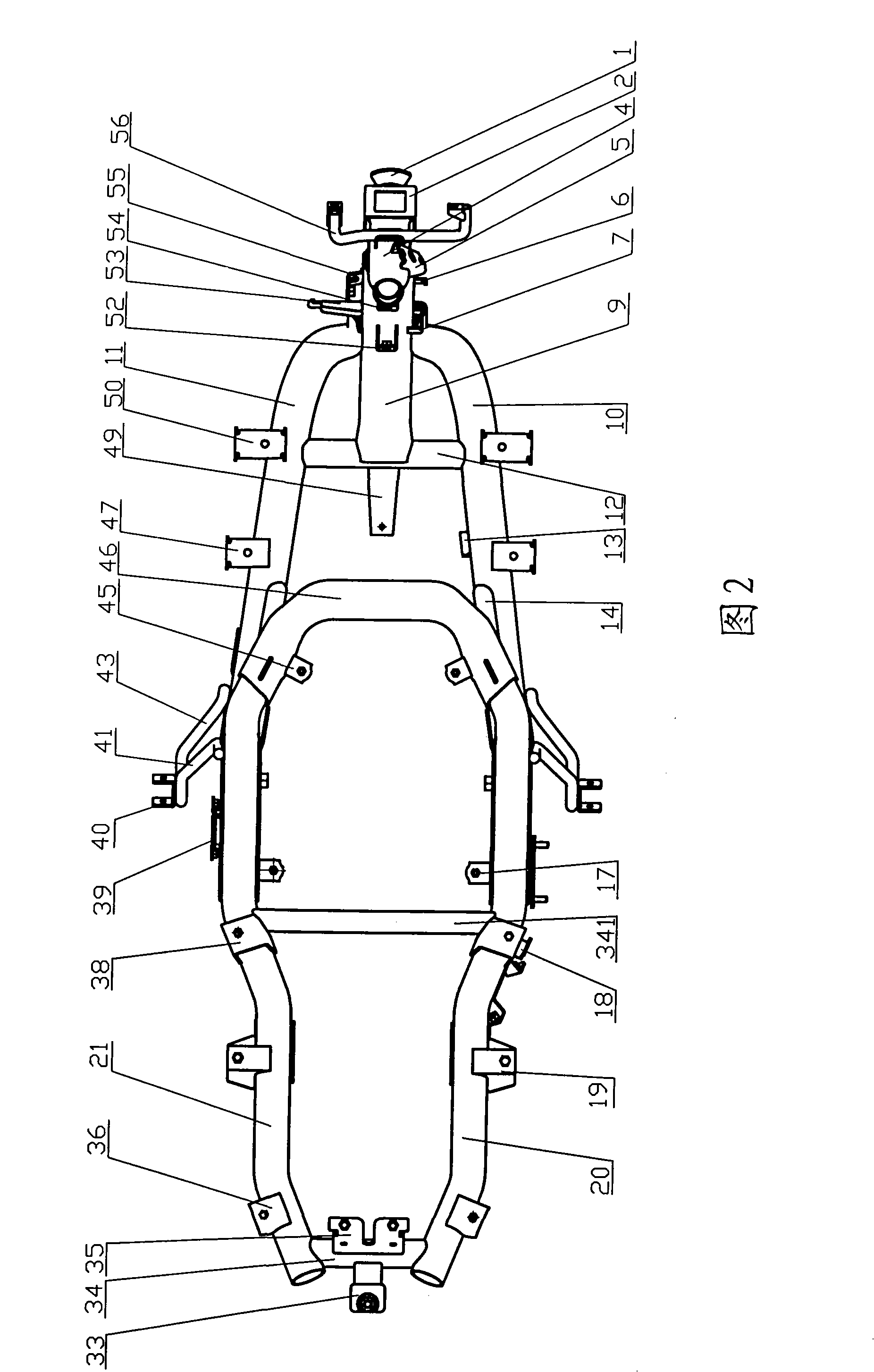

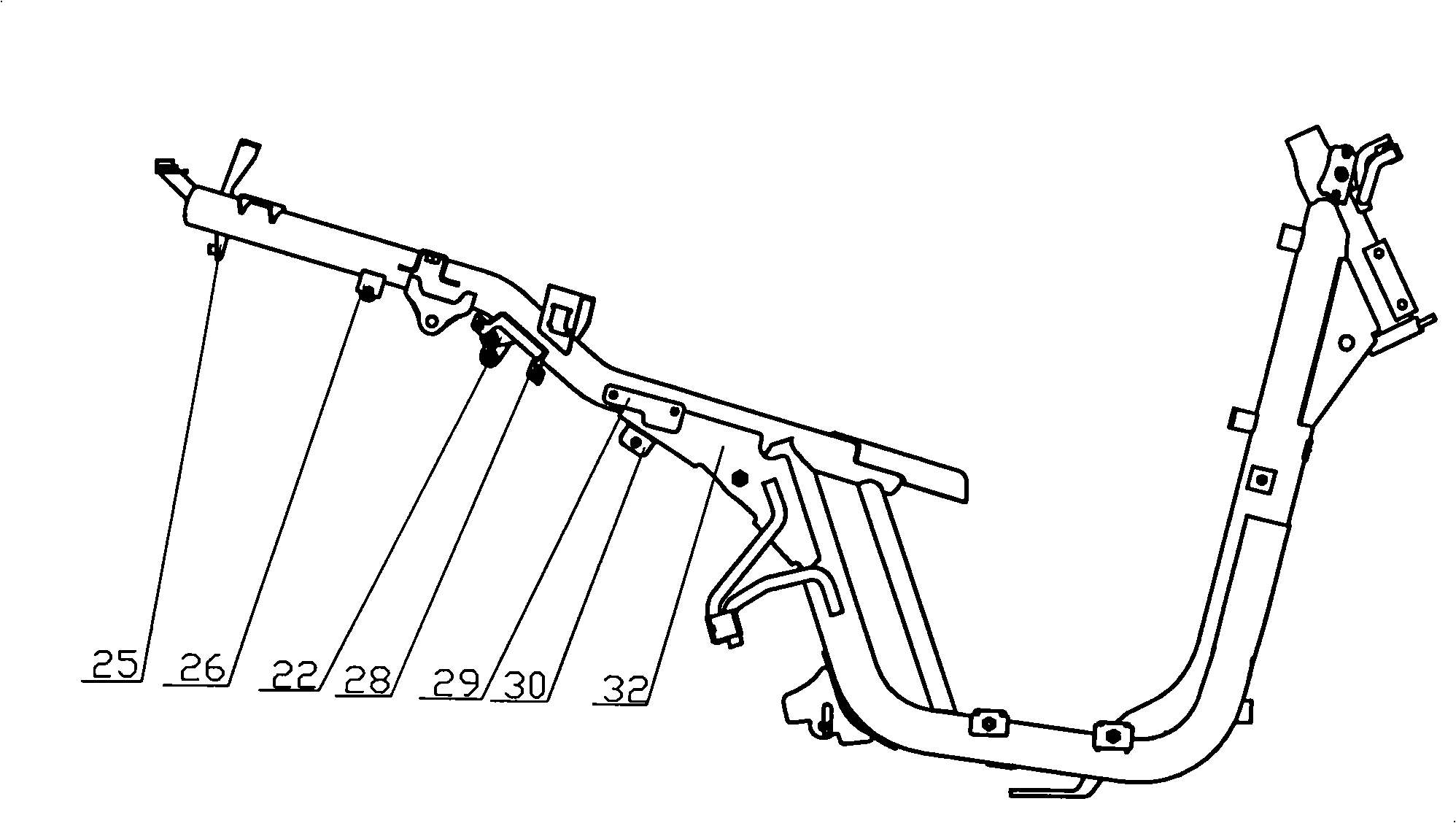

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Figure 1, Figure 2, Figure 3 and Figure 4 As shown, the motorcycle frame structure of the present invention comprises a main beam 9 of a vehicle frame, and the top of the main beam 9 of the vehicle frame is connected with the vertical pipe 4 of the vehicle frame; The left and right sides of the middle and lower part of the frame main beam 9 are symmetrically arranged (welded respectively) to be a U-shaped right lower tube 10 and a U-shaped left lower tube 11, and the U-shaped bottoms of the right lower tube 10 and the left lower tube 11 are used to support the feet together. Pedal, the two ends of lower beam 12 are welded with the U-shaped bottom of right lower pipe 10 and left lower pipe 11, and this welding point is best near the front bend of U-shaped bottom. The end of the right lower pipe 10 is welded to the bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com