Direct driving type multi-stroke multi-well oil pumping machine

A pumping unit, multi-stroke technology, applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of complex equipment structure, increase investment and energy consumption, etc., and achieve convenient oil pumping management and simple structure , the effect of saving weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

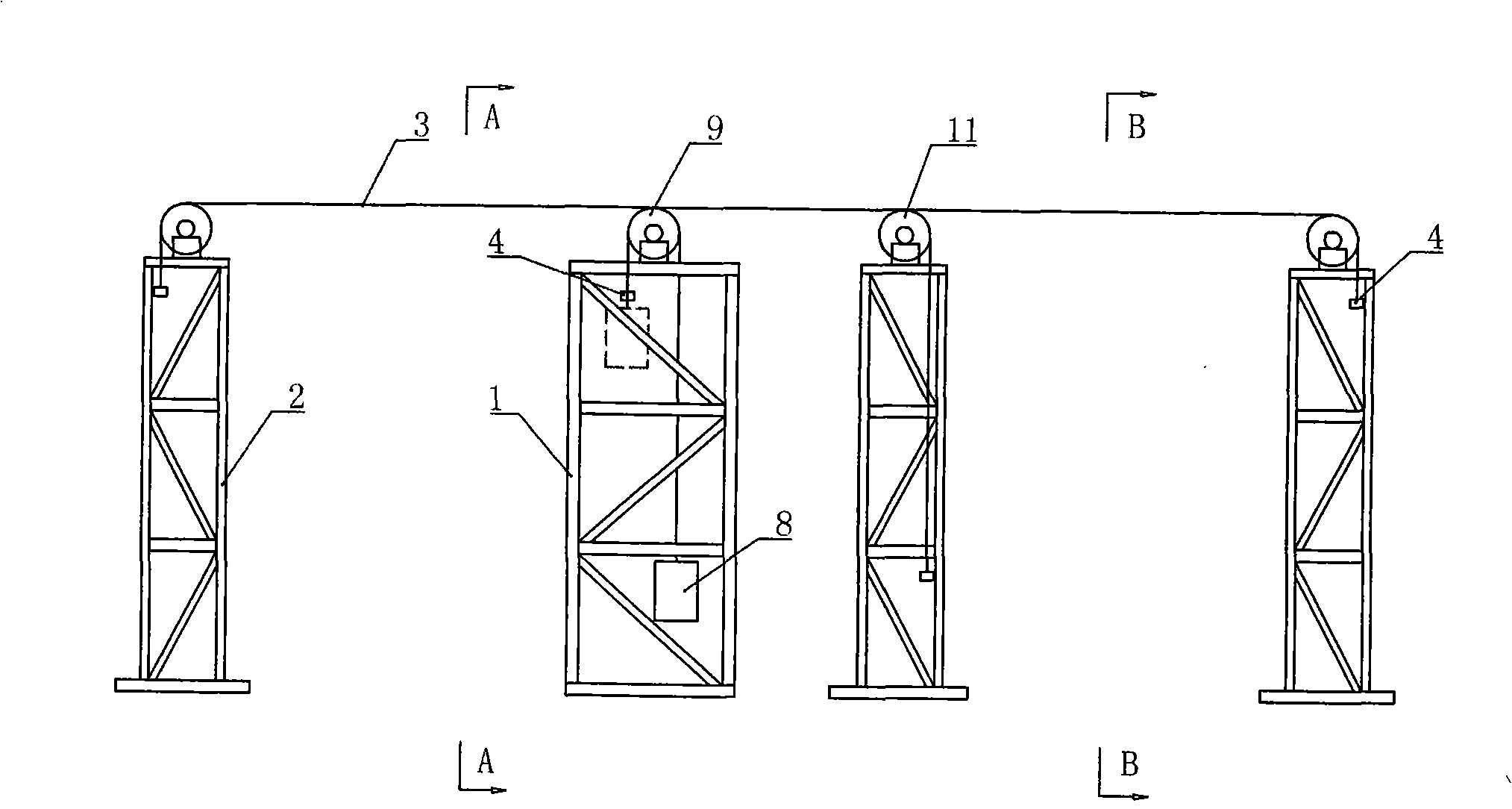

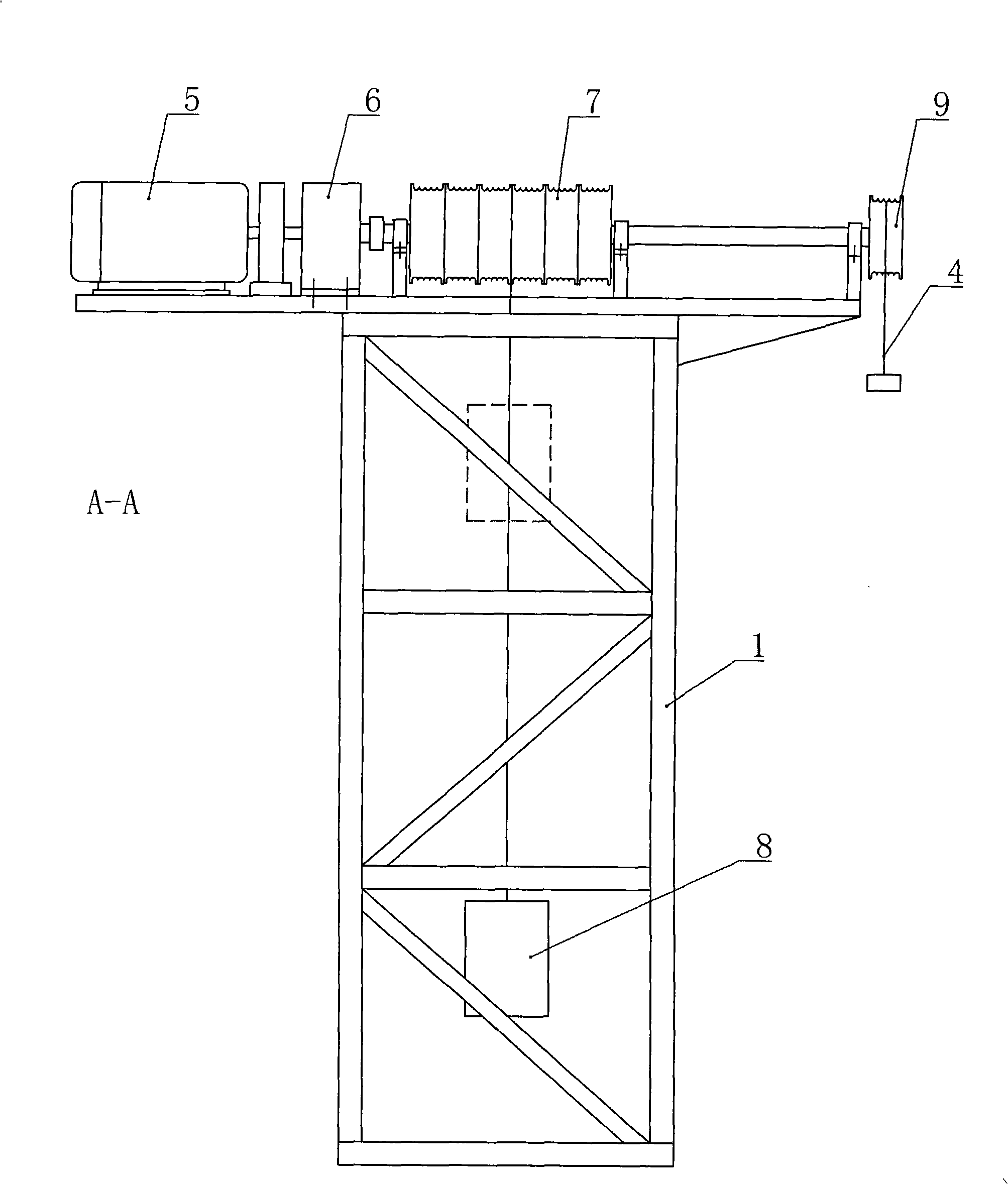

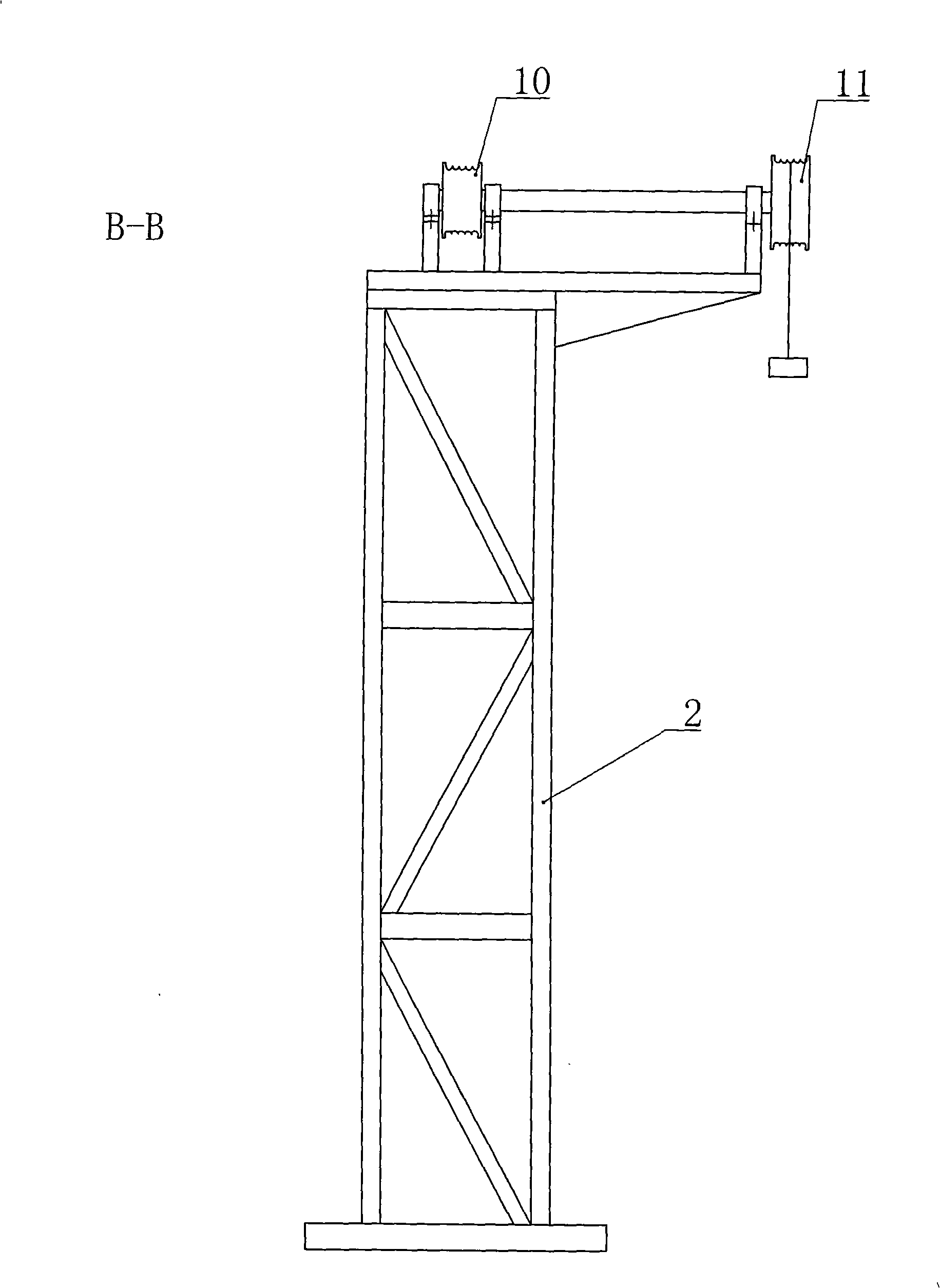

[0016] Now in conjunction with accompanying drawing and specific embodiment the present invention is further described as follows:

[0017] From Figure 1 ~ Figure 3 Visible, the present invention comprises main support 1 and the power unit that is installed on its top, and this power unit comprises frequency conversion motor 5, suspension weight roller 9 and rope hanger 4, and the output shaft of frequency conversion motor 5 is transmitted through speed changer 6 and suspension weight roller 9 Connect, be connected with hanging rope device 4 on this suspended load roller 9. Sub-supports 2 are arranged around said main support 1, and power rollers 10 and coaxial suspension rollers 11 are installed on each sub-support 2, and a rope suspension device 4 is connected to each suspension suspension roller 11. ; A power roller 7 coaxial with the suspension roller 9 is connected to the output end of the transmission 6 ; there are different slots on the power roller 7 on the main supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com