Construction method for spanning railway, highroad or 6KV alive power line without using spanning frame when expanding optical cable of new lines

A live line and spanning frame technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of complex geographical environment, high construction difficulty, increased cost, etc., and achieve the effects of improving economic benefits, reducing construction costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

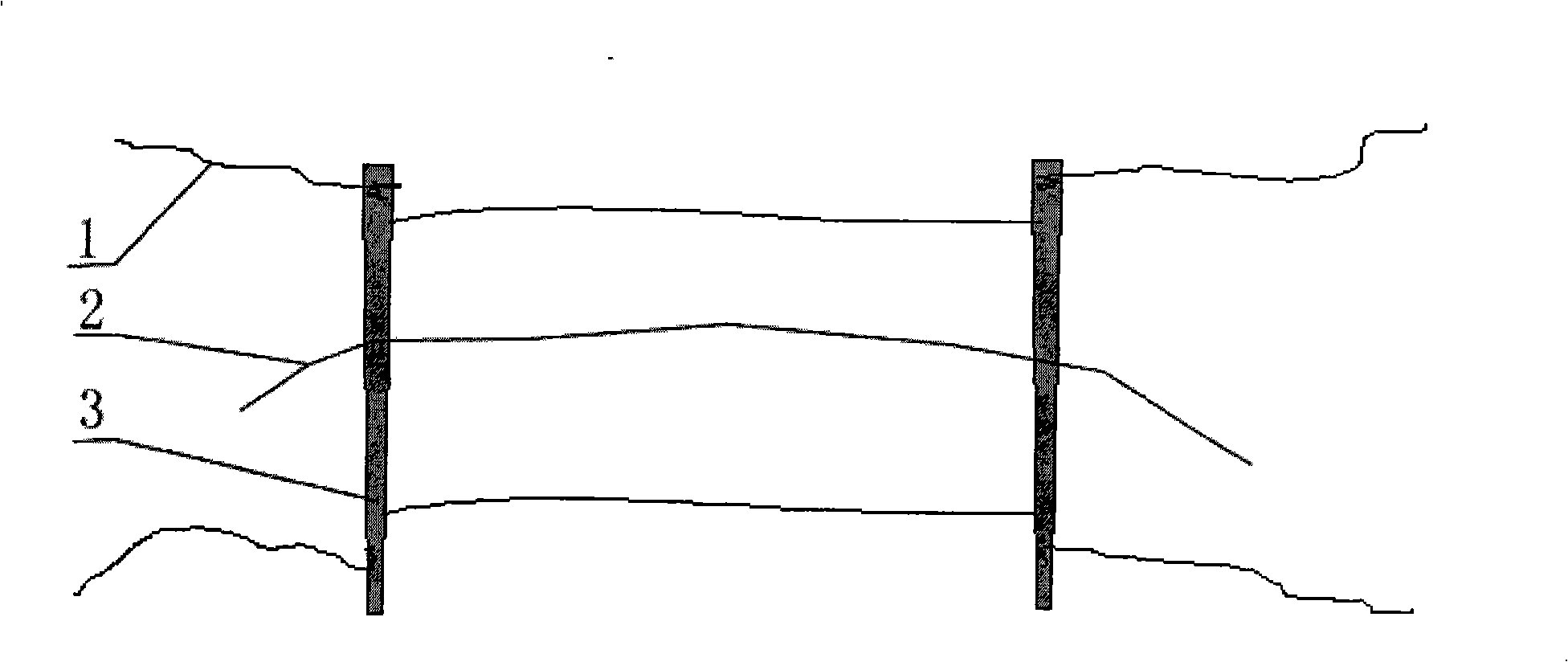

[0019] Embodiment 1. On-site survey: survey the height, width, crossing angle, terrain of the crossing point, etc. of the crossing power line, and determine the setting plan without erecting the spanning frame.

[0020] 1. First, assemble a temporary spanning frame on the ground according to the distance between the two sides of the original line and the spanning distance between the live line and the two sides;

[0021] 2. Assembly of the temporary spanning frame: connect two scaffolding poles with insulating ropes to form a rectangular spanning structure, and then connect one insulating rope for fixing to the two ends of each scaffolding pole. Reserve an insulated traction rope, reserve the traction rope to ride on the two scaffolding poles, and reserve the traction rope long enough to touch the ground at both ends;

[0022] 3. According to the installation position of the temporary spanning frame, nail 4 fixed ground anchors on the ground.

[0023] 4. After the temporary s...

Embodiment 2

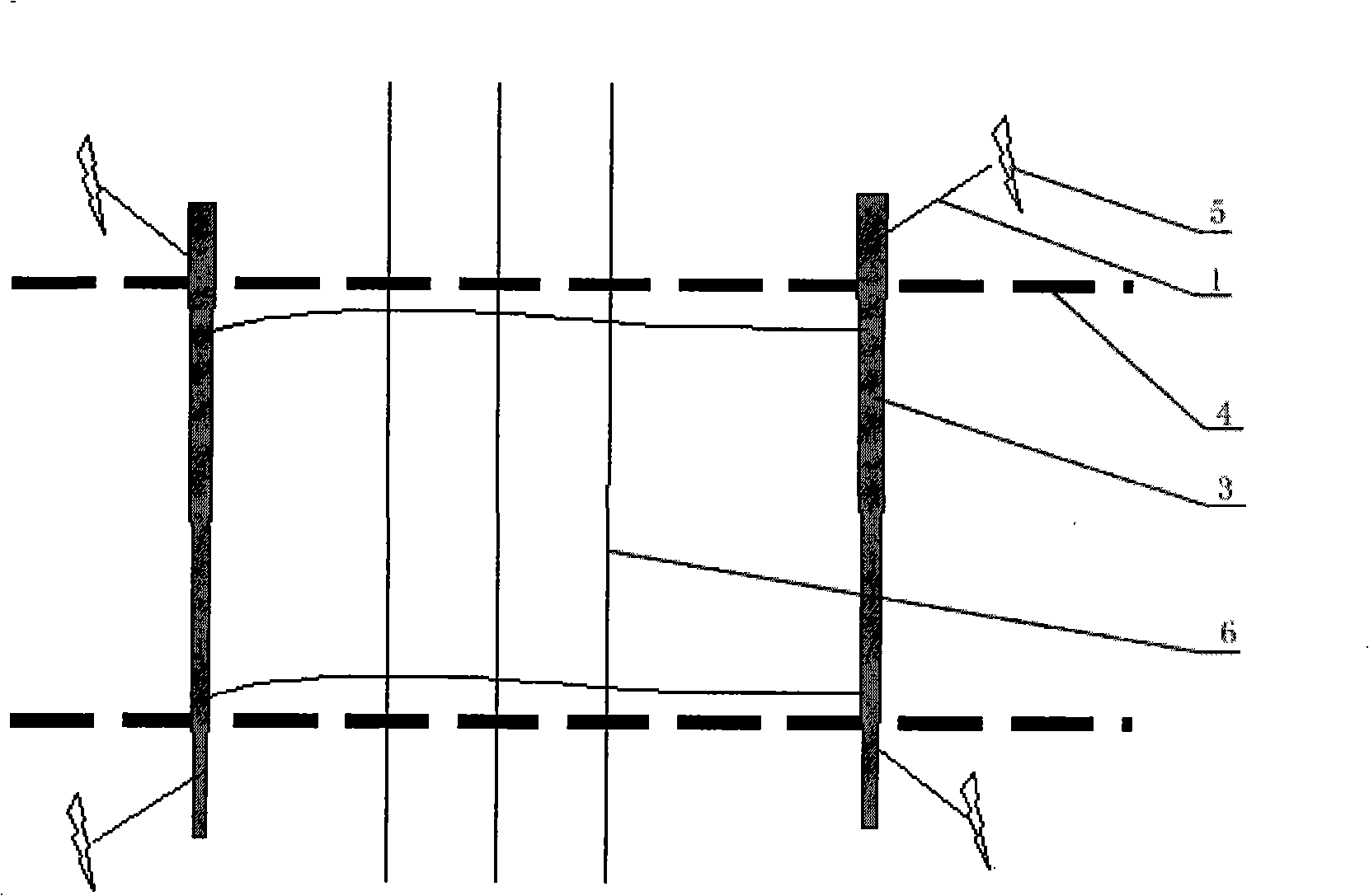

[0028] Embodiment 2, take crossing the railway as an example:

[0029] 1. First, according to the distance between the two sides of the original line, assemble a temporary spanning frame on the ground: connect the two scaffolding rods with insulating ropes to form a rectangular spanning structure, and then connect 4 fixed insulating wires to the two ends of the two scaffolding rods. An insulated traction rope is reserved between the two scaffolding poles. As shown in the picture:

[0030] 2. According to the installation position of the temporary spanning frame (that is, the width of the railway), drive 4 fixed ground anchors on the ground.

[0031] 3. After the temporary spanning frame is assembled, first use the insulating measuring rope (thinner) to throw over the side phase of the newly built line, and use this insulating measuring rope to pull the insulating ropes on the side of the two scaffolding poles across the two sides of the original line. The two sides of the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com