Magnetic component integrated active clamp positive and negative laser converter

A converter, forward and flyback technology, applied in the field of converters, can solve the problems of large volume and weight, and achieve the effect of reducing the magnetic flux density, reducing the total volume and total weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

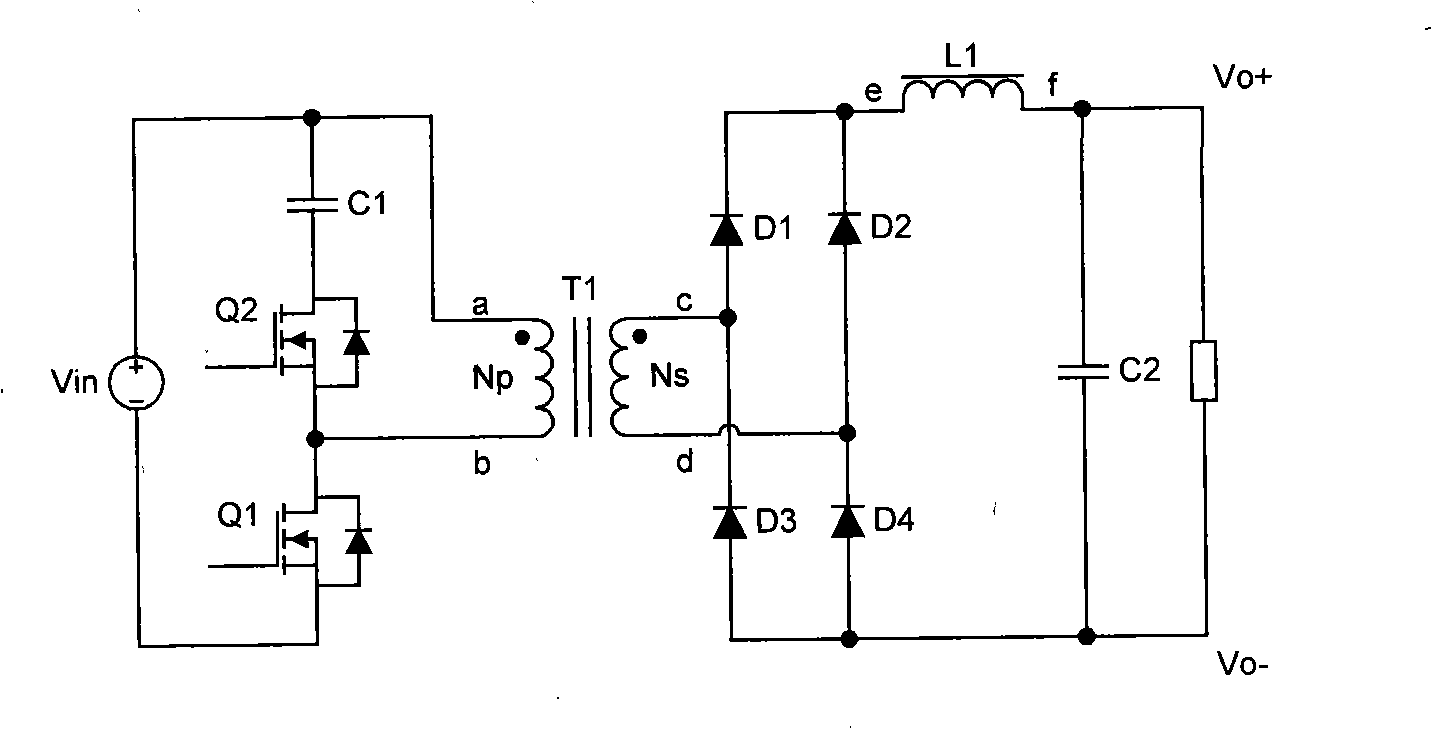

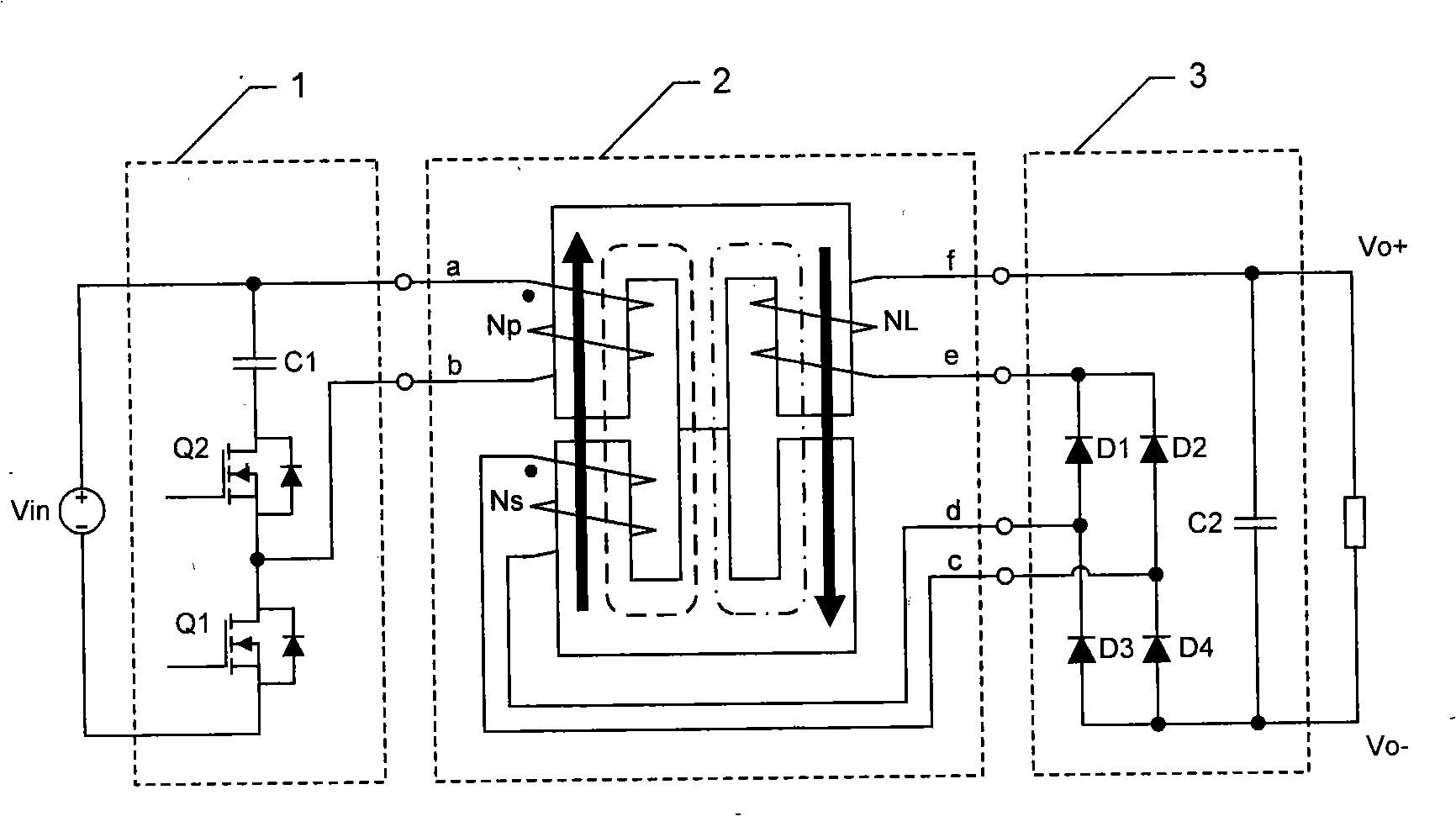

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

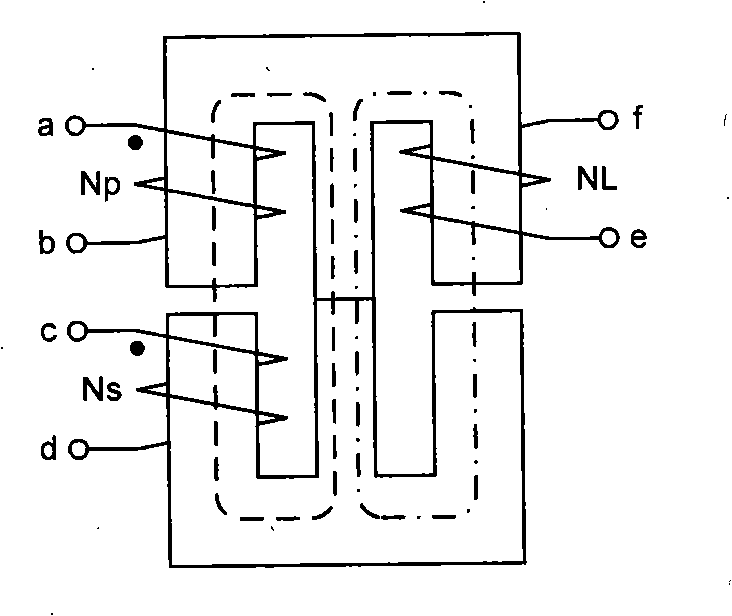

[0028] figure 2 Shown is the structural diagram of the first integrated magnetic element of the present invention, its function is equivalent to figure 1 Transformer T1 and filter inductor L1 in. The iron core of the integrated magnetic element includes at least three magnetic columns. In this embodiment, it consists of two E-shaped iron cores with opposite openings. The primary winding Np and the secondary winding are wound on one side of the iron core to form a transformer magnetic circuit. ; The inductance winding NL is wound on the iron core on the other side to form an inductive magnetic circuit; the central magnetic column of the iron core forms the common magnetic circuit of the transformer magnetic circuit and the induct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com