Automatic temperature-control metal electric heating membrane

A metal electric heating film and self-controlling temperature technology, applied in electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of random heating of local temperature, exceeding the standard, etc., and achieve a simple structure, low cost, and improved reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

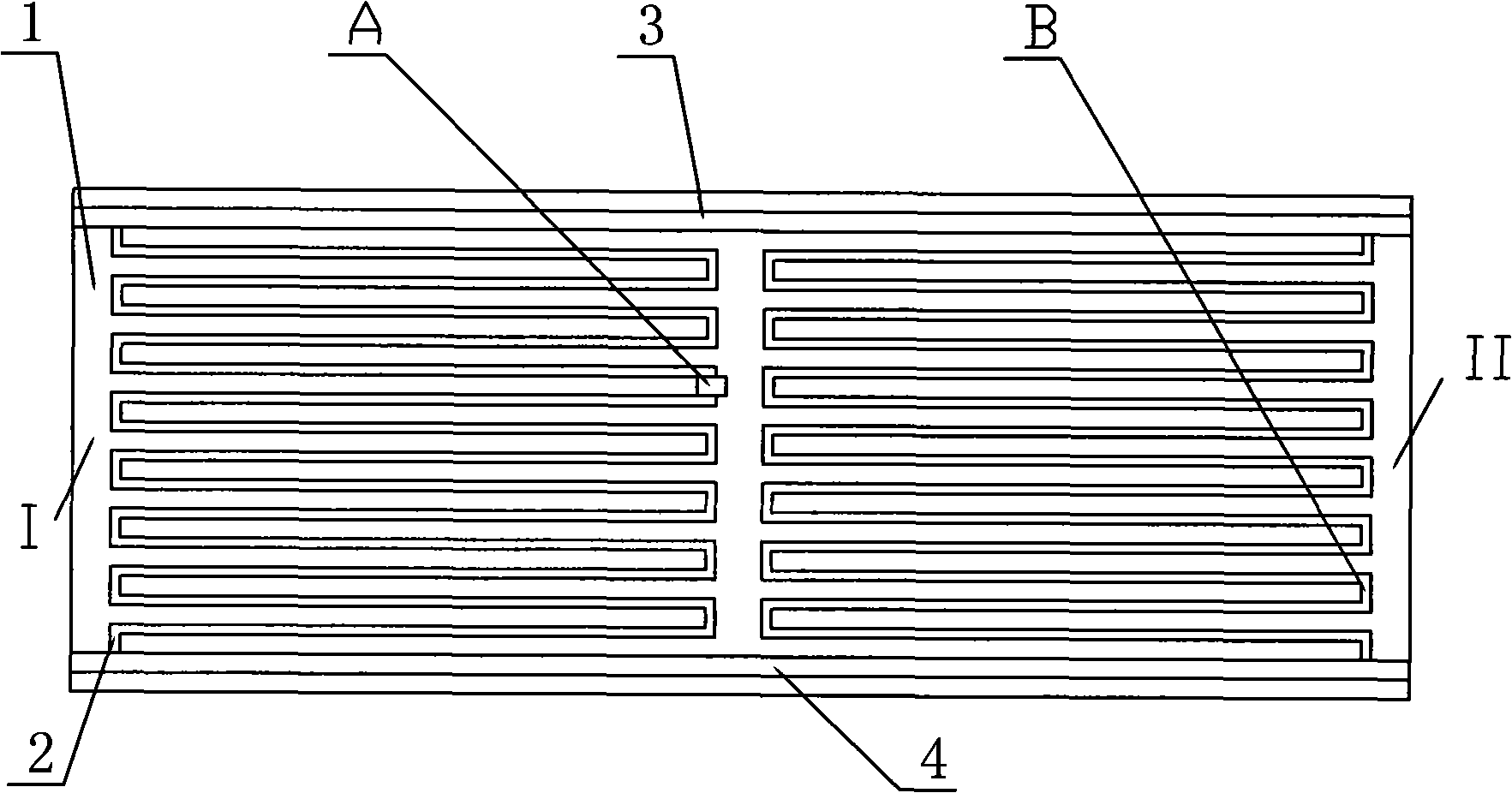

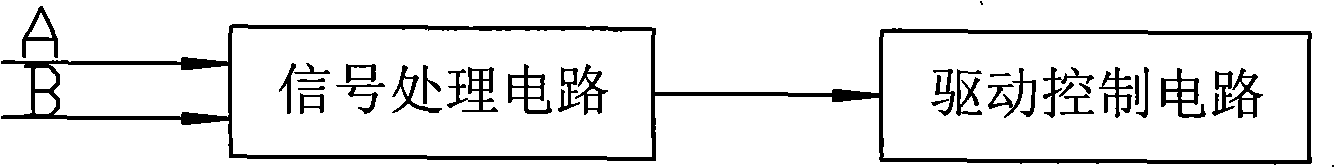

[0014] Example 1 as figure 1 , figure 2 Shown: Same as the prior art, there is a double-layer insulating film 1, a conductive line 2 is built in the double-layer insulating film 1, and an input bus 3 and an input bus 4 are connected to the conductive line 2, which are different from the prior art It is to directly lead out the wire on the conductive line 2 of unit I as the potential detection point A, and the potential reference point B only provides a reference value for the potential detection point A, which can be as follows figure 1 As shown, it is arranged on the conductive line 2 of another unit II, and may also be arranged on the insulating film 1, the input bus 4, etc. of another unit II. The signal processing circuit can be the same as the prior art, such as signal comparison circuit, signal amplification circuit, analog / digital conversion circuit, microprocessor and OR gate and other circuits; the driving execution circuit can be circuits such as relays. When the ...

Embodiment 2

[0015] Example 2 as image 3 Shown:

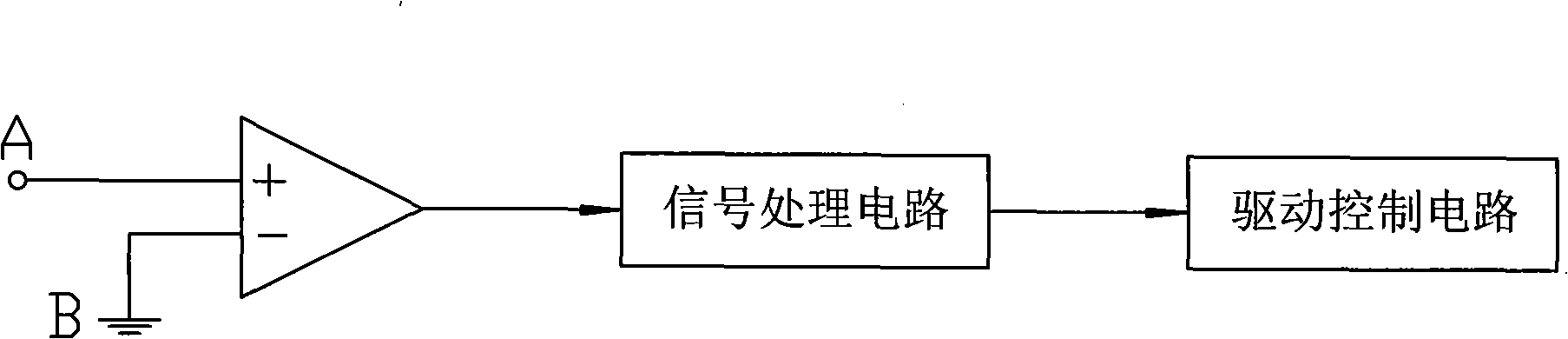

[0016] Same as the prior art, there is a double-layer insulating film 1, and a conductive circuit 2 is built in the double-layer insulating film 1, and an input bus 3 and an input bus 4 are connected to the conductive circuit 2. What is different from the prior art is that it is conductive The potential detection point A is directly set on the line 2, the potential detection point A is connected to the input terminal of the comparator I in the signal processing circuit, and the potential reference point B is the comparison voltage set at the other input terminal of the comparator I, the potential detection point A and potential reference point B are compared by a comparator, and its output is connected to the drive execution circuit through other circuits of the signal processing circuit (signal amplification circuit, analog / digital conversion circuit, microprocessor and OR gate).

Embodiment 3

[0017] Example 3 as Figure 4 , 5 Shown:

[0018] Same as the prior art, there is a double-layer insulating film 1, and a conductive circuit 2 is built in the double-layer insulating film 1, and an input bus 3 and an input bus 4 are connected to the conductive circuit 2. What is different from the prior art is that it is conductive There is a potential detection point A on the line 2, and the voltage reference point B is the contact point of the series resistor R1 and the adjustable resistor R2, the other end of the resistor R1 is connected to the input bus 3, and the other end of the adjustable resistor R2 is connected to the input bus 4 connected. The outputs of the potential detection point A and the potential reference point B are connected with the drive execution circuit through the signal processing circuit as in the first embodiment.

[0019] Potential detection point A divides the conductive line 2 of the metal electrothermal film into two sections to form resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com