Filter with self-cleaning rotating filter element

A filter and self-cleaning technology, which is applied in the direction of mobile filter element filter, filter separation, chemical instrument and method, etc., can solve the problems such as the inability to automatically clean the filter element and the failure of the filter element, so as to reduce the cost of cleaning or replacing the filter element, prevent Clogging, the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

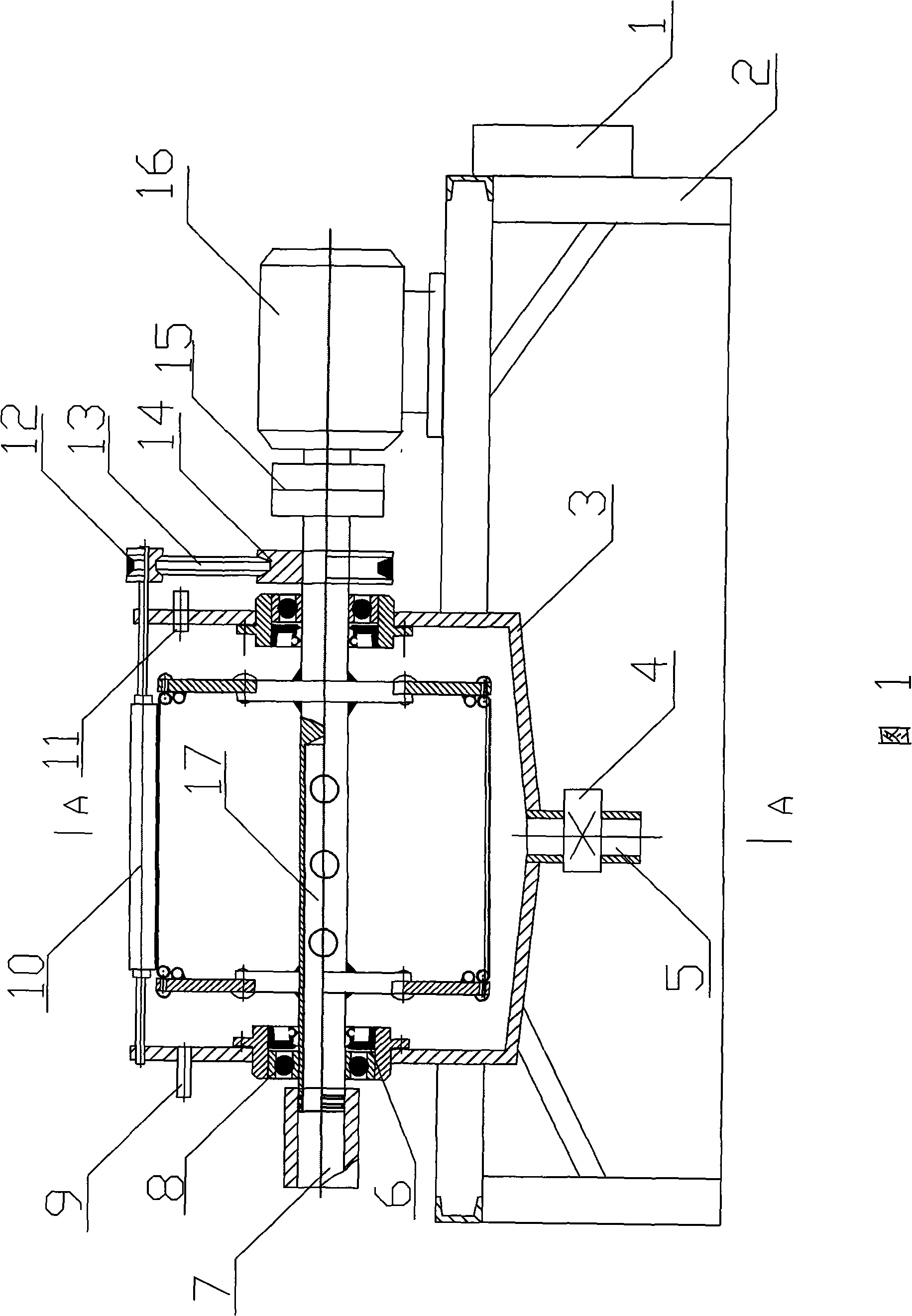

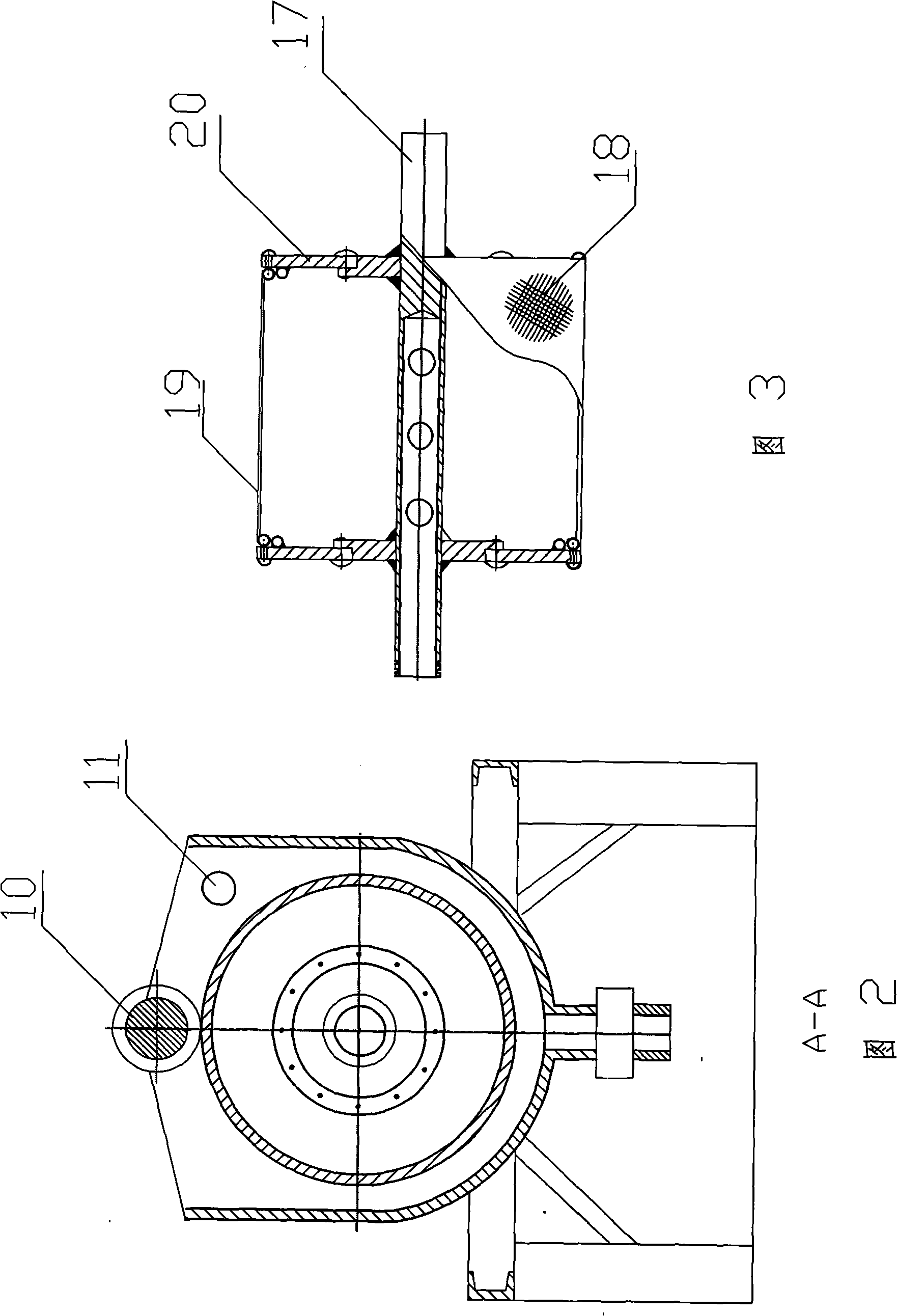

[0019] The technical solution of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0020] Referring to shown in Fig. 1, the present invention is made of filter main body (3), filter core (17) with hollow shaft, bearing (8), seal (6), swivel joint (7), cleaning roller brush (10), Electro-pneumatic valve (4), sewage pipe (5), electrical control box (1), motor (16), coupling (15), overflow device (9), liquid inlet pipe (11), frame ( 2), belt (13), large pulley (14), small pulley (12) steel frame (20), steel wire mesh (19), filter material (18) and other accessories are formed.

[0021] See Figure 1:

[0022] The electrical control box (1) is an electrical system control box with a time setting control system.

[0023] The electrical control box (1) controls the operation of the electric motor (16) and the electro-pneumatic valve (4) respectively.

[0024] The electrical control box (1), the filter main body (3), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com