Movable uprooting weeding robot

A mobile and robotic technology, applied in the direction of land preparation machinery, agricultural machinery and implements, etc., can solve the problems of slow moving speed of the device, large degree of soil damage, and reduced weeding efficiency, so as to reduce power demand, improve weeding effect, The effect of reducing the frequency of weeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

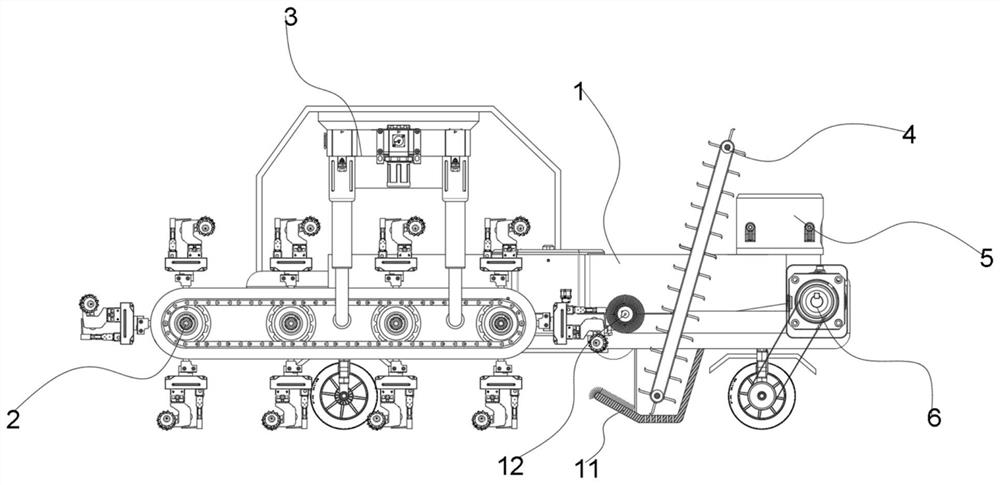

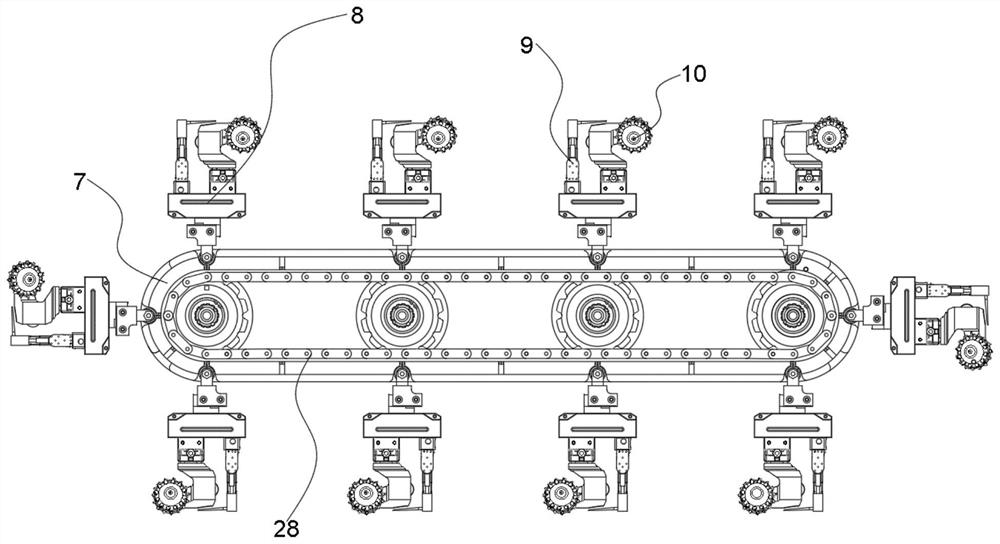

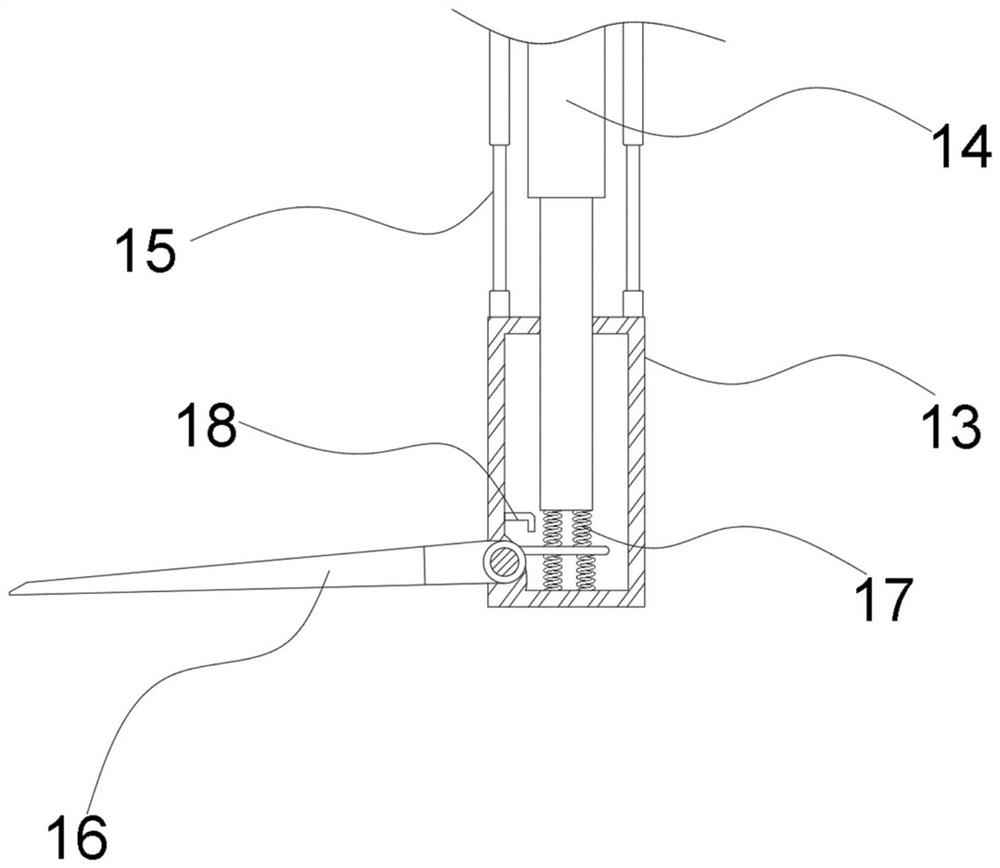

[0035] see figure 1 , in an embodiment of the present invention, a mobile rooting weeding robot, which includes a mobile bracket 1 and a weeding device 2, wherein the lower end of the mobile bracket 1 is provided with a plurality of driving wheels, and the driving wheels at the rear are composed of The high-frequency motor 6 fixed on the mobile bracket 1 is driven to rotate; the front and rear sections of the weeding device 2 are fixed on the top of the mobile bracket 1 through the double-arm cylinder 3: the right side of the weeding device 2 is provided with a The conveyor belt 4 on the 1 is used to transport the weeds falling from the weeding device 2 to the collection box 5 fixedly installed behind the mobile support 1;

[0036] The right side of the mobile support 1 is also provided with a cleaning brush 12, and the cleaning brush 12 always rotates counterclockwise at a constant speed, and is used to help the weed removal device 2 fall off and clean it.

[0037] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com