Mobile bracket, formwork integral system and method for constructing continuous beam

A mobile and bracket technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of poor construction turnover, poor safety performance, large amount of steel, etc., and achieve short construction period, high safety and stability, The effect of saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

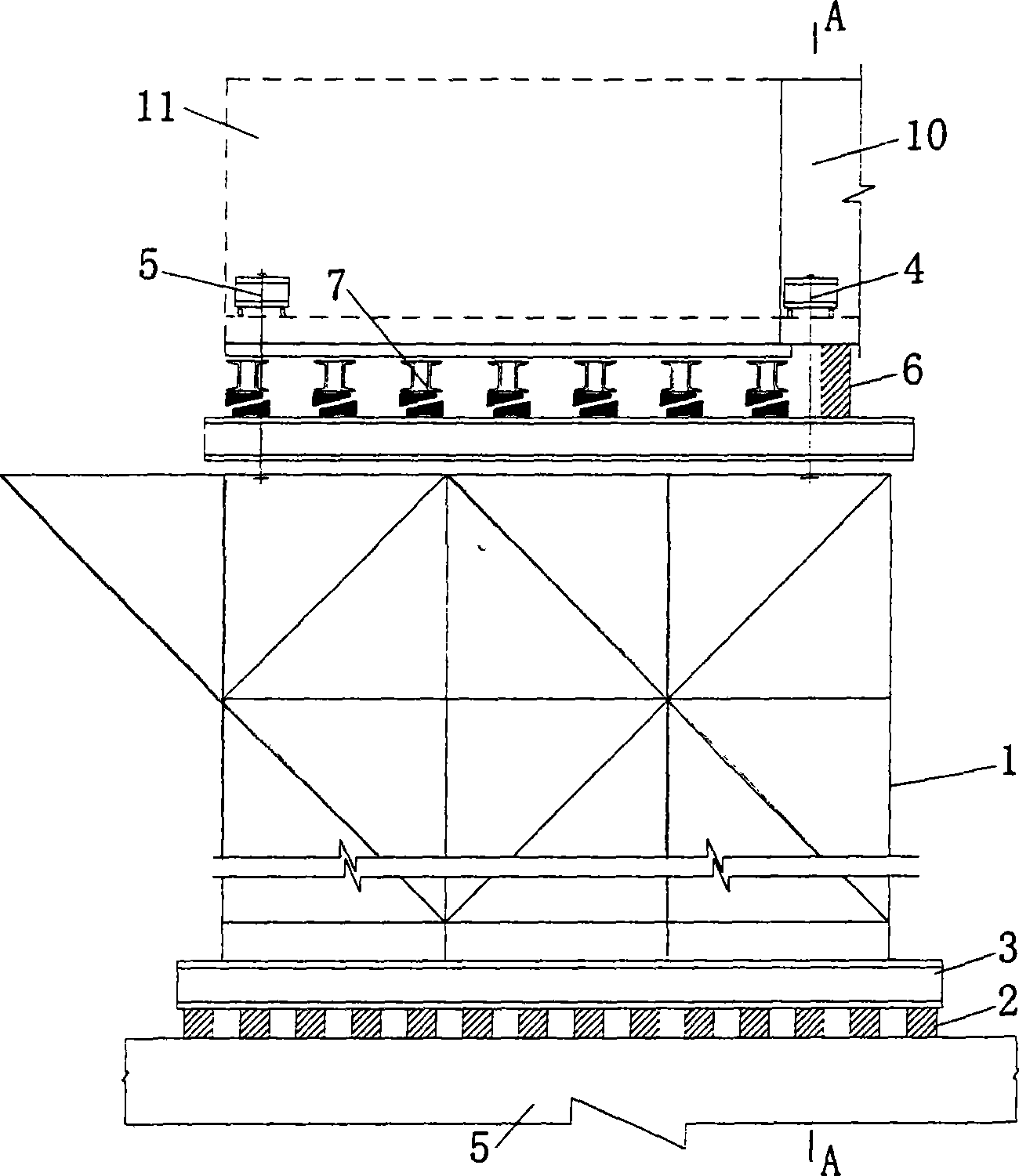

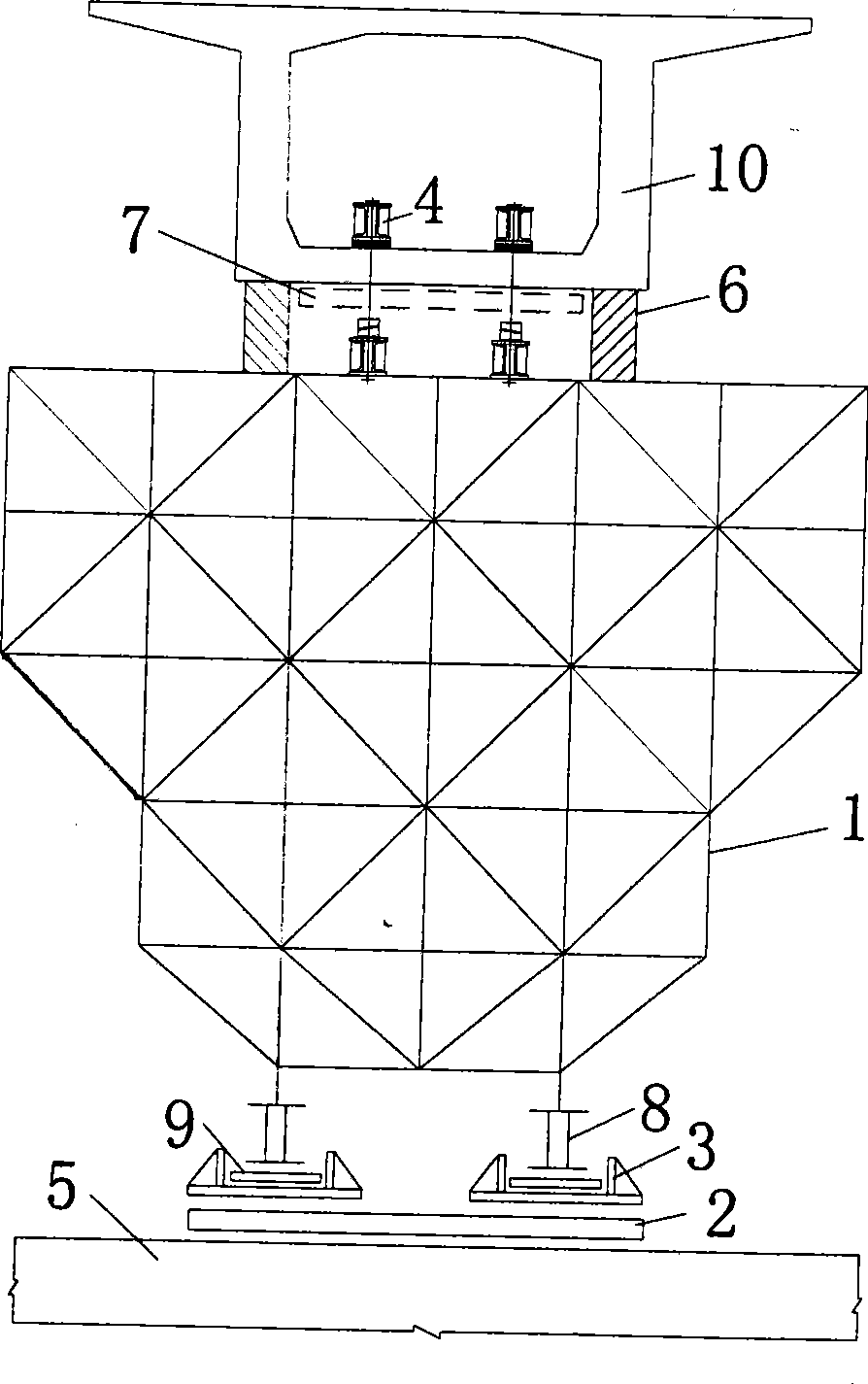

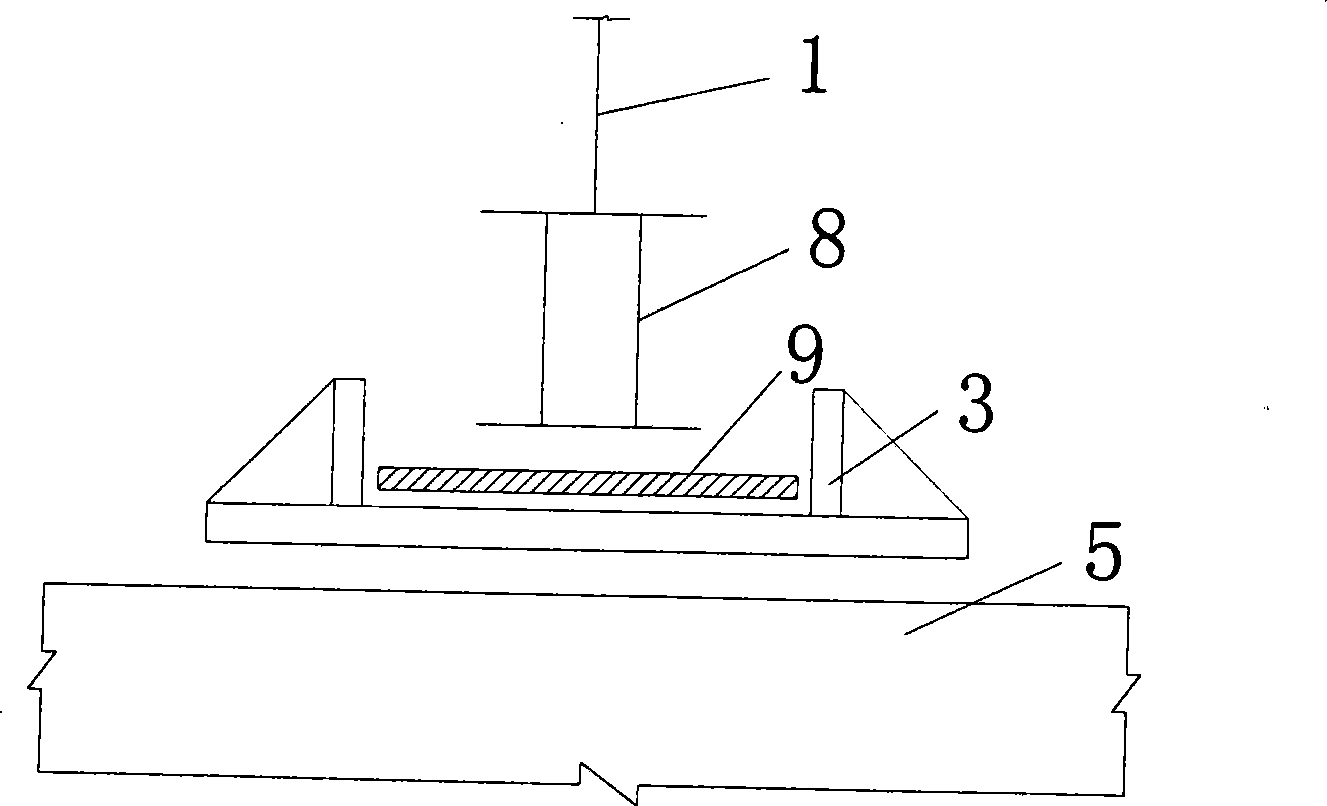

[0018] With reference to accompanying drawings 1 and 2, its structure is to lay sleeper 2 on the completed main structure 5 below the construction beam body, set chute 3 on sleeper 2, and moveable bracket 1 and chute 3 are installed on sleeper 2 Above, the distribution beam 8 at the bottom of the bracket and the movable bracket 1 are welded firmly, the distribution beam 8 at the bottom of the bracket and the chute 3 are in contact with the PTFE plate 9, and at the connecting end of the movable bracket 1 and the constructed section 10 After installation, the hanging system 4 and the steel block jacking device 6 are installed to anchor the mobile bracket 1 and the constructed segment 10, and the beam formwork 7 is installed on the top surface of the mobile bracket 1 to form a whole with the bracket, and the construction beam solid concrete.

[0019] The mobile bracket 1 is an integral construction support bracket assembled from universal rods. The universal rod mobile bracket h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com