Control method of engine electric air throttle

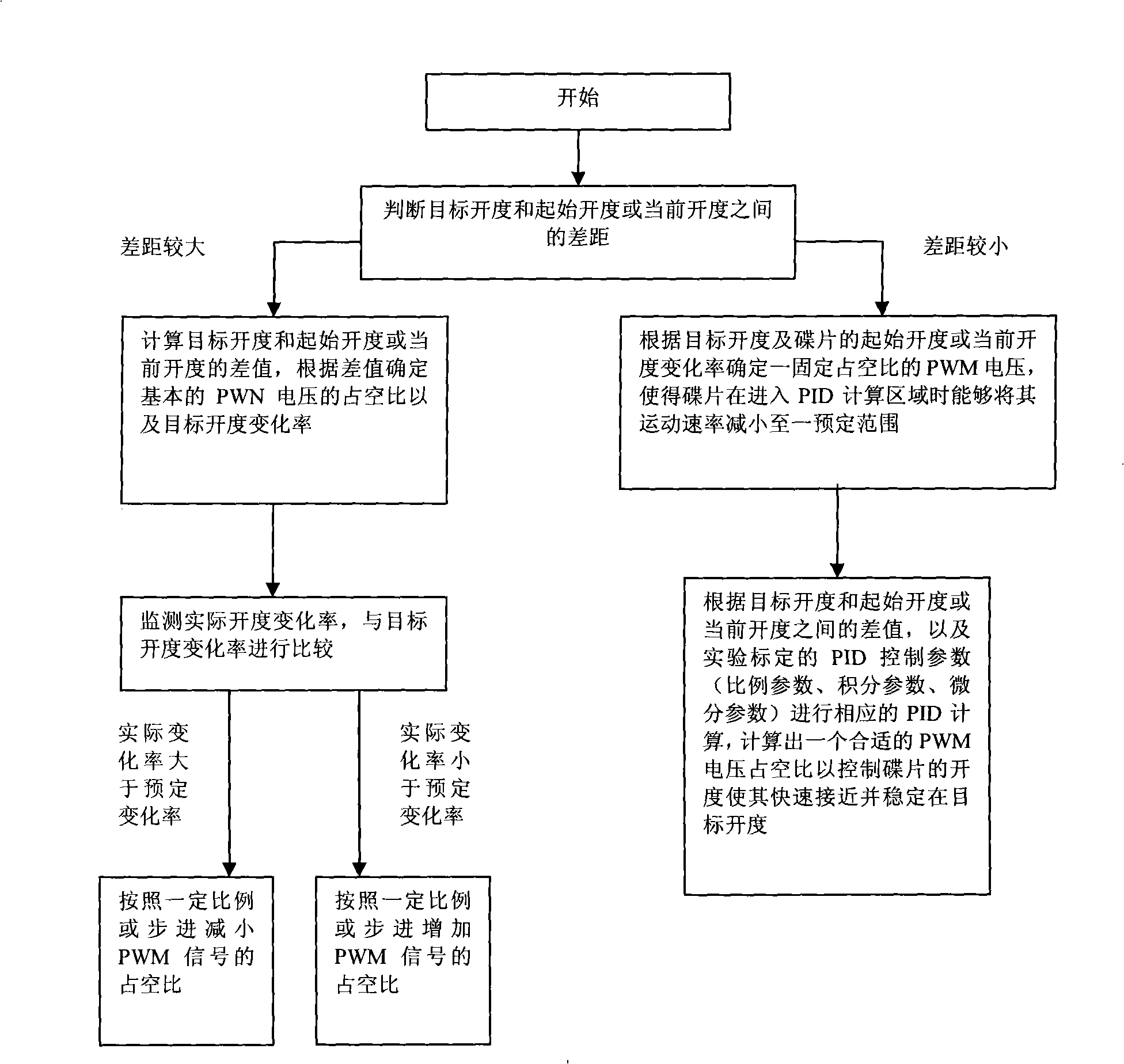

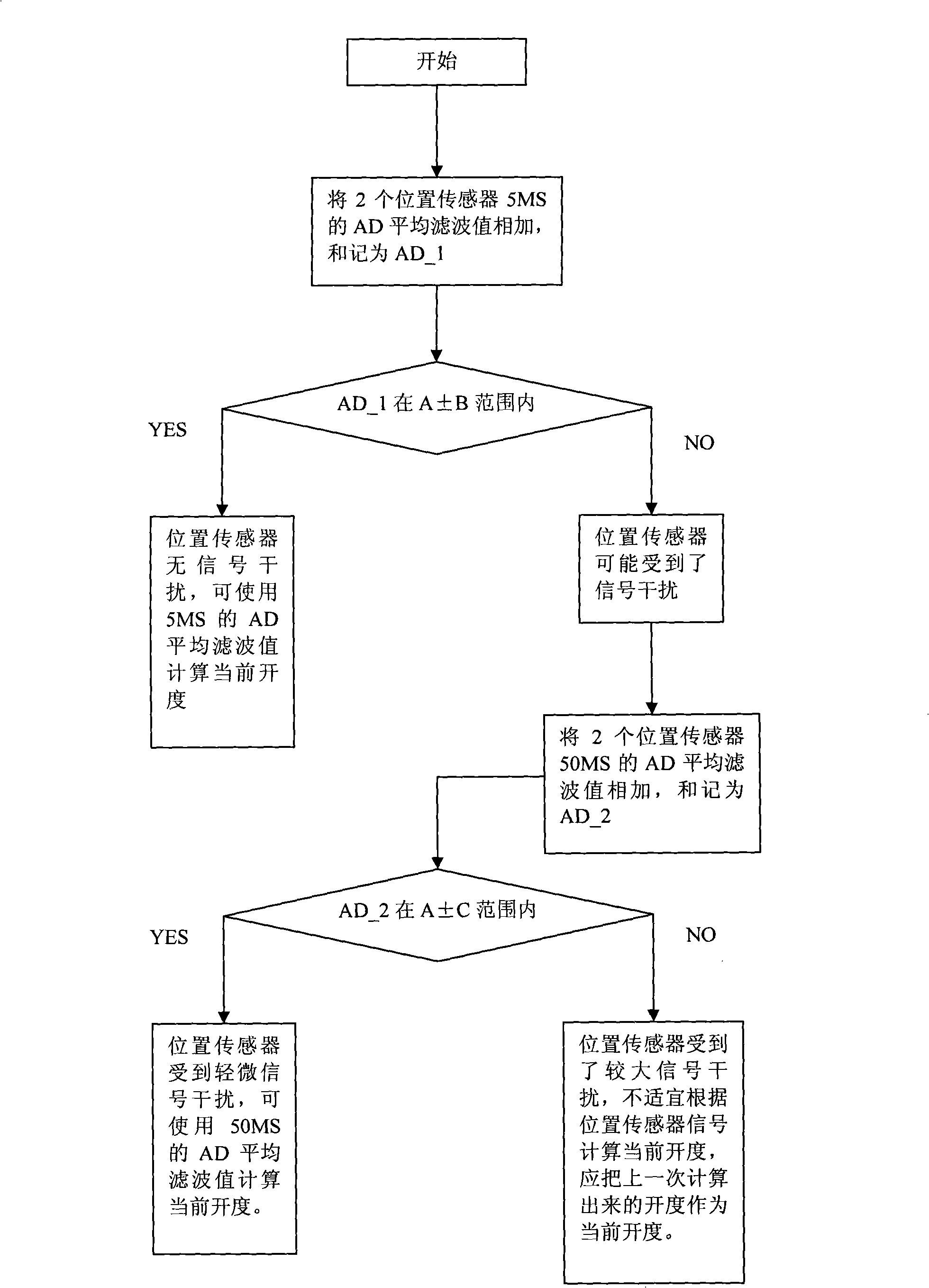

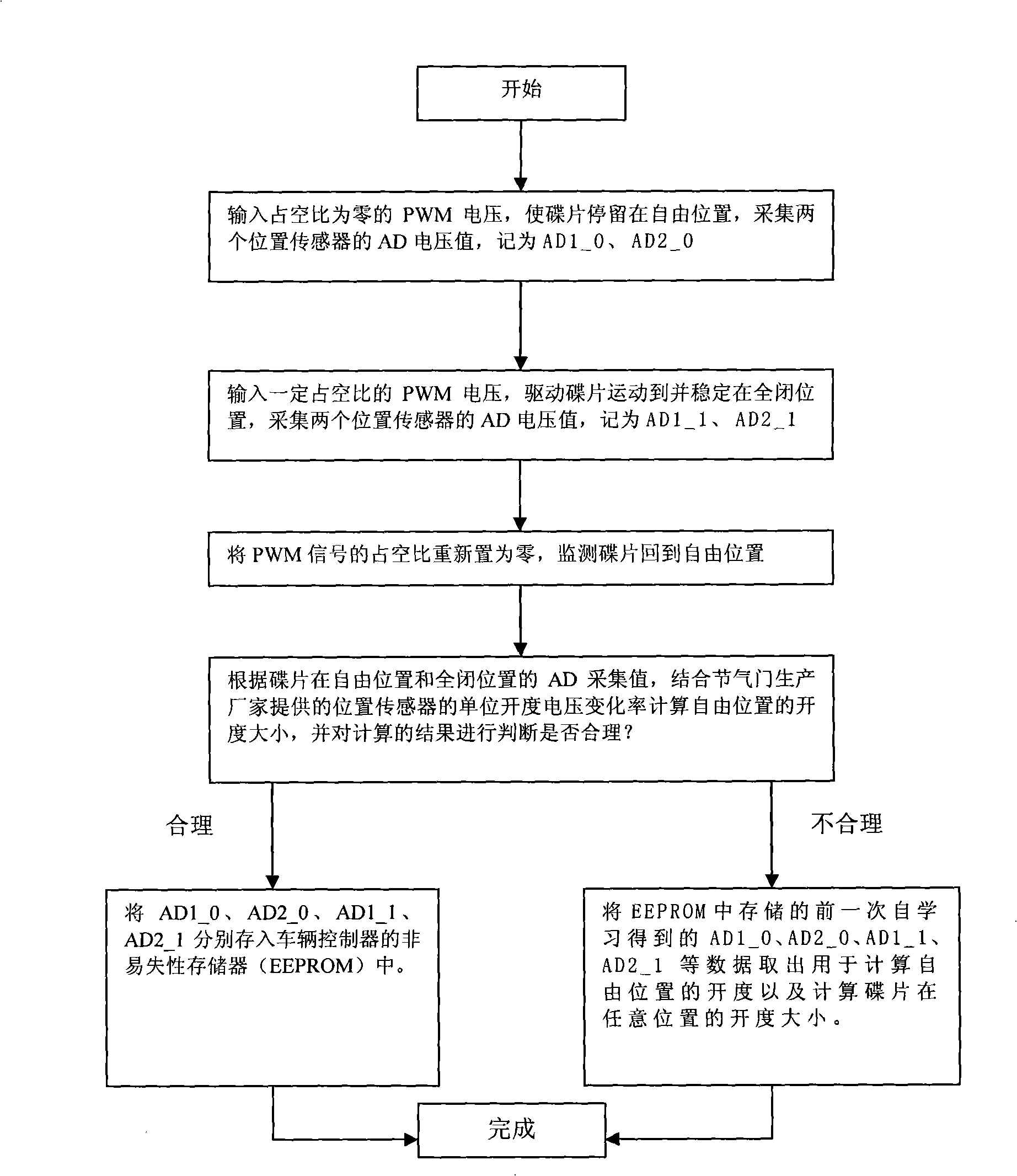

An electronic throttle valve and control method technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of complex friction, unbalanced torque, difficult influence, etc., achieve fast and stable operation, prevent overshoot, The effect of accurate overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Before describing the control method of the present invention in detail, a brief introduction to the basic structure of the electronic throttle is given first. The electronic throttle system mainly includes: accelerator pedal position sensor. The accelerator pedal position sensor is composed of two non-contact linear potentiometer sensors working at the same reference voltage. The reference voltage is provided by the ECU. As the position of the accelerator pedal changes, the potential The resistor value also changes linearly, thus generating a voltage signal that reflects the amount of movement of the accelerator pedal and the rate of change of the accelerator pedal to input the ECU; the throttle position sensor, the throttle position sensor is also composed of two non-contact linear potentiometer sensors Composed, and the same reference voltage is provided by the ECU, when the throttle position changes, the resistance of the potentiometer also changes linearly, thus gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com