Rechargeable air battery and manufacturing method thereof

An air battery pack and air cathode technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, lithium batteries, etc., can solve the problems of limited rechargeability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

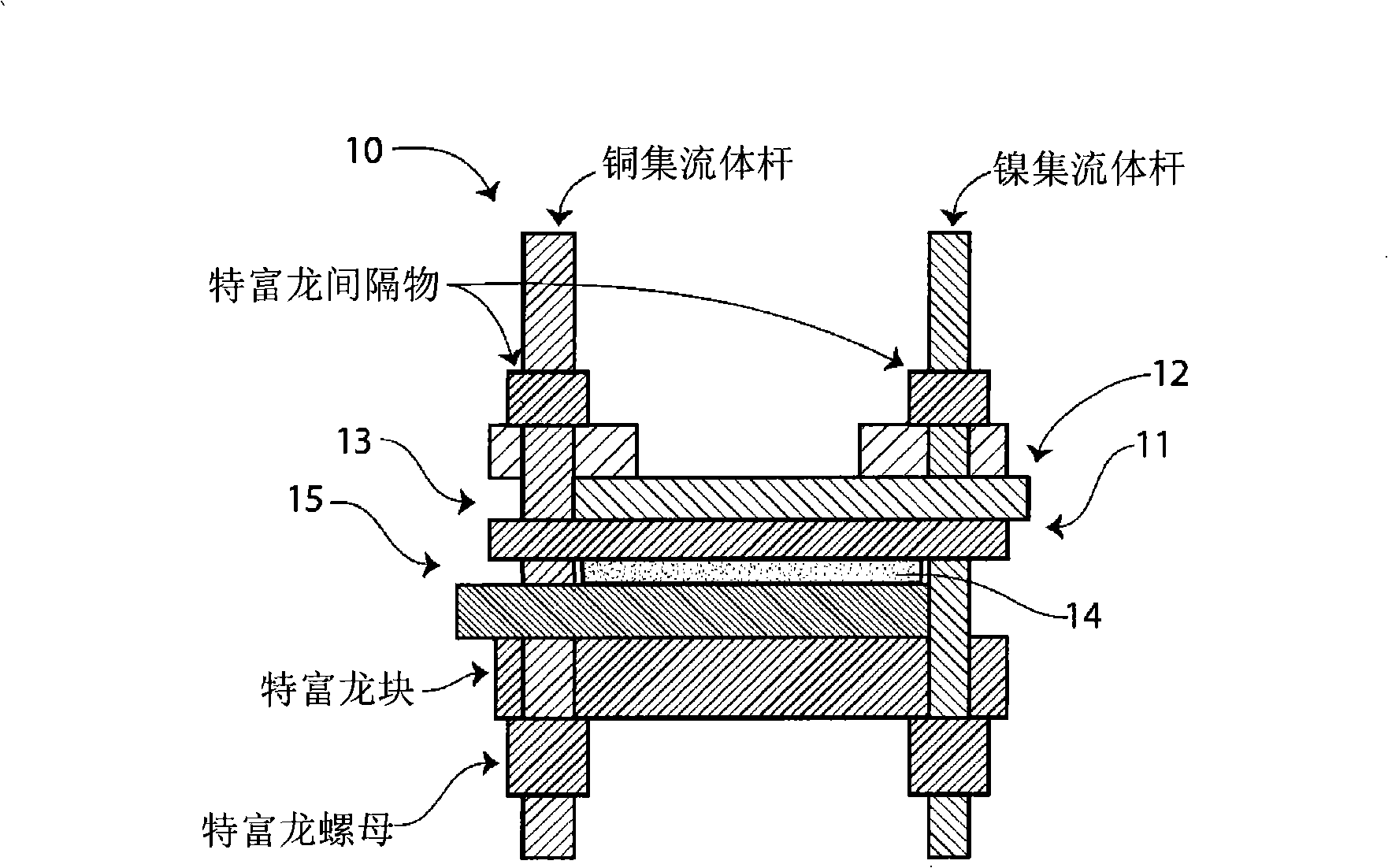

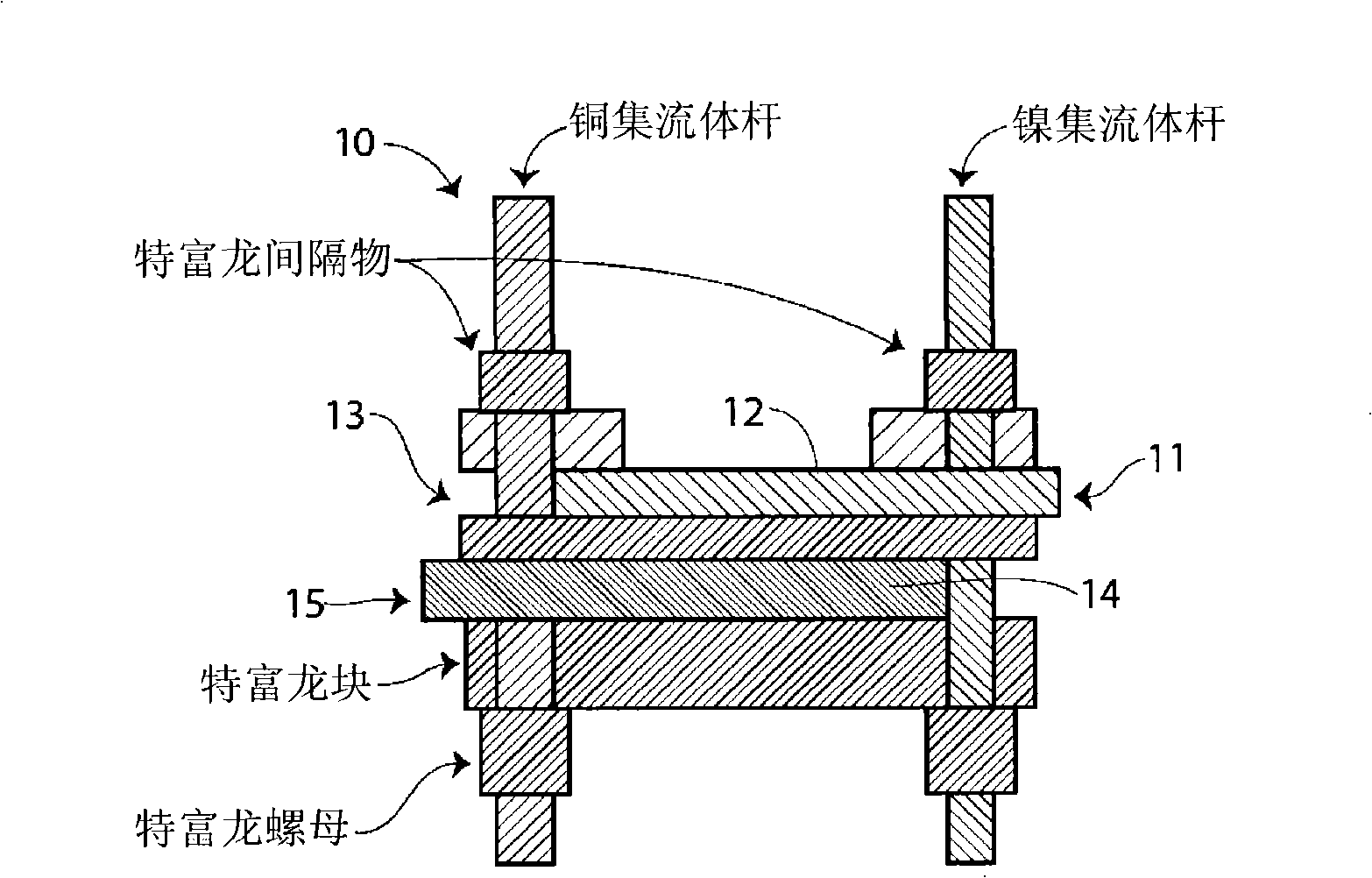

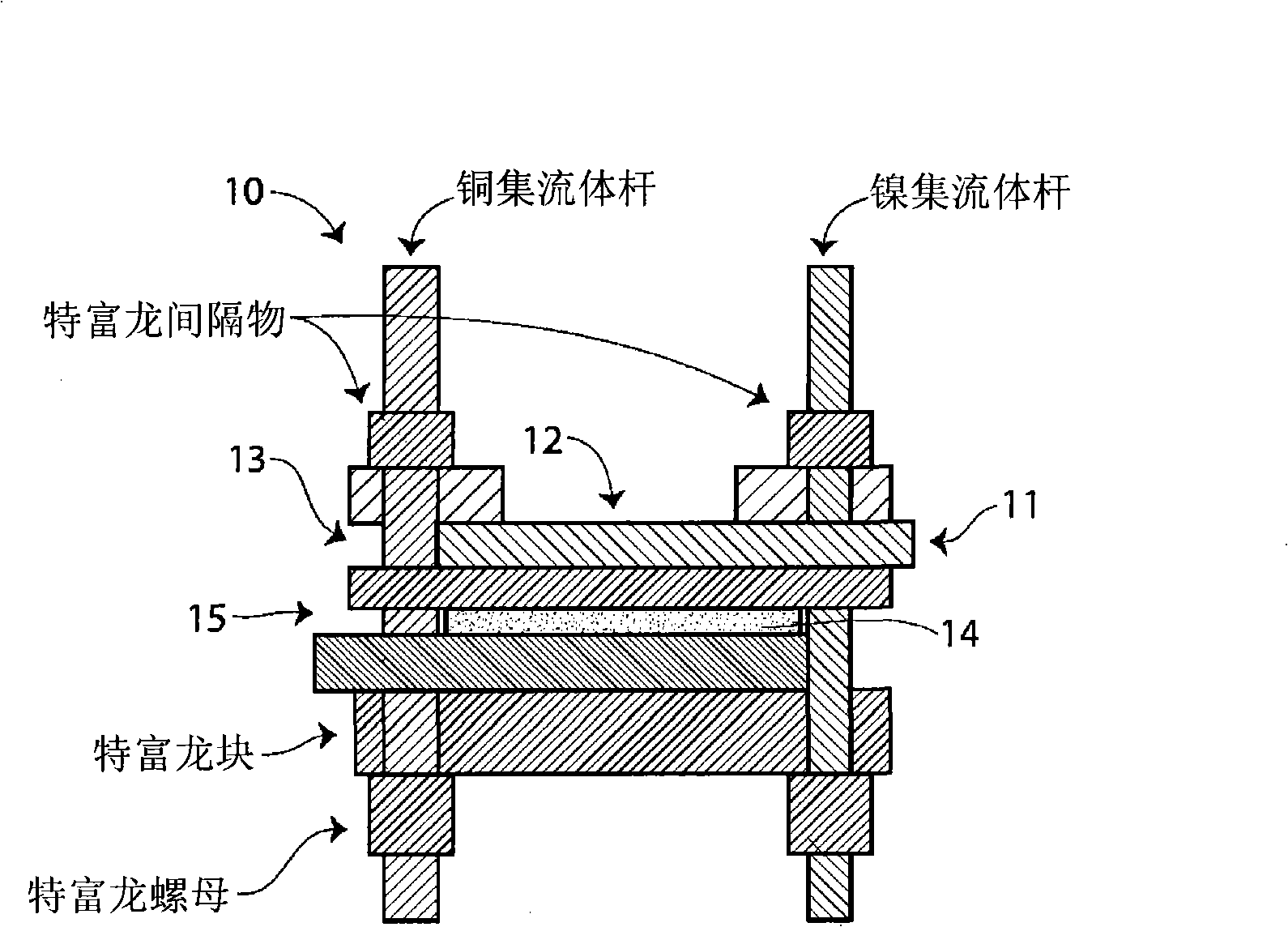

[0026] Referring next to the drawings, there is shown a battery or electrochemical cell 10 embodying the principles of the invention in a preferred form and a method of production thereof. Cell 10 includes air cathode 11 , cathode current collector 12 , separator 13 , anode 14 and anode current collector 15 .

[0027] To produce cell 10, prepare by first wetting 14.22 g of Calgon carbon, 0.56 g of acetylene black and 0.38 g of electrolytic manganese dioxide with 60 ml of a mixture of isopropanol and water (1:2 by weight) Teflon bonded Calgon carbon (activated carbon) based air cathode 11 . Electrolytic manganese dioxide is a redox catalyst, preferably provided in a concentration of 1% to 30% by weight. Alternatives to electrolytic manganese dioxide are ruthenium oxide, silver, platinum and iridium. Next, 2.92g of Teflon 30 (60% Teflon emulsion in water) was added to the above mixture, mixed, and placed in a jar with ceramic balls to mix overnight on a roller. After mixing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com