Valve assembly for connecting a heat exchanger of a hot water discharging device to a district heating system

A technology of valve device and heat exchanger, which is applied in the field of valve device and can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

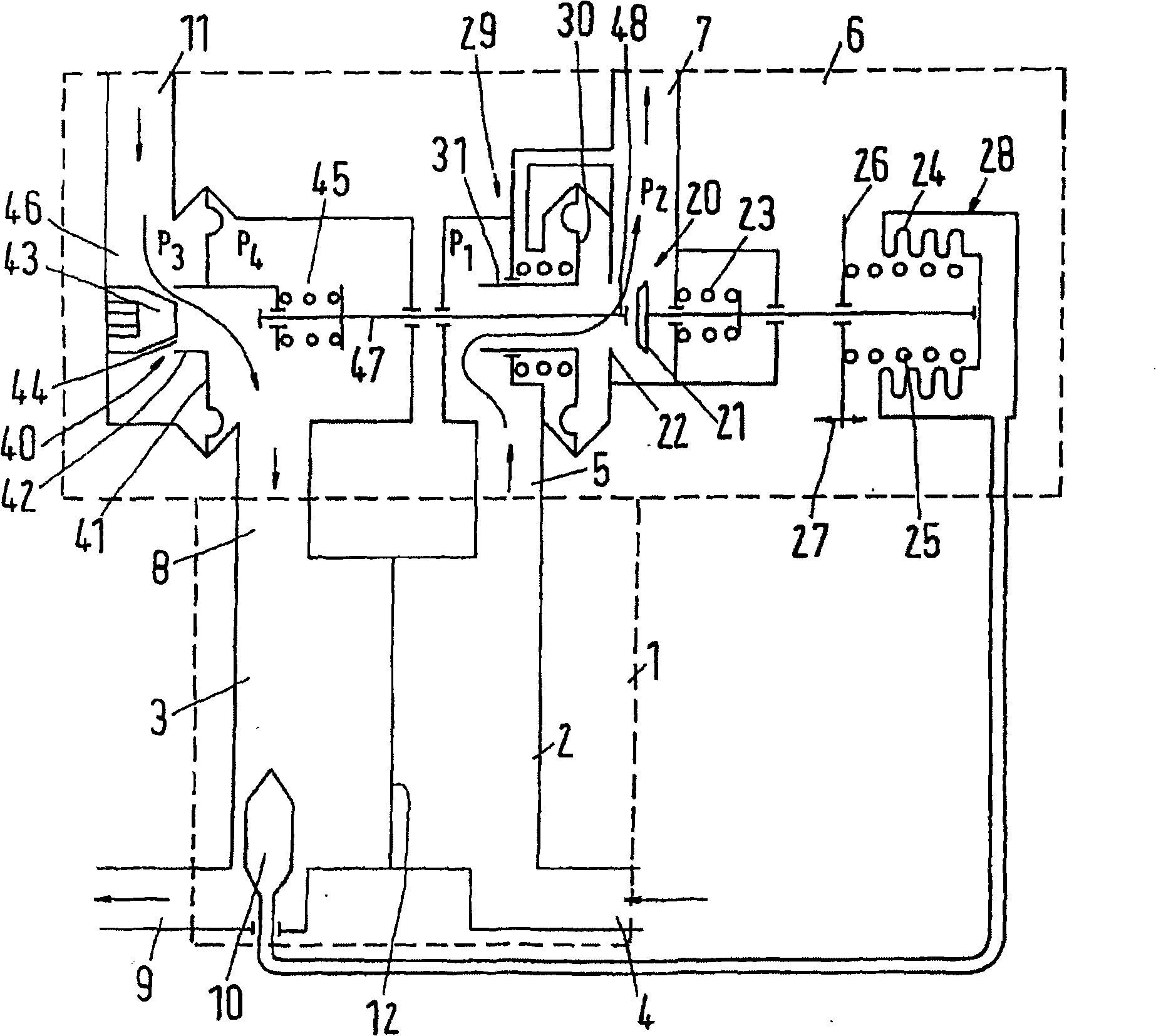

[0024] figure 1 A heat exchanger 1 with a primary side 2 and a secondary side 3 is shown schematically. The primary side 2 has an inlet 4 which is connected to a district heating system, not shown in detail. The primary side 2 also has an outlet 5 which is connected via a valve arrangement 6 to a return connection 7 of the district heating network.

[0025] The secondary side 3 has an inlet 8 for the inflow of water and an outlet 9 from which heated water can be drawn off. In the area of the outlet 9 there is a temperature sensor 10, the function of which will be explained further below. The inlet 8 of the secondary side 3 is connected via a valve arrangement 6 to a water connection 11 for supplying cold water.

[0026] The heat exchange surface 12 is arranged between the primary side 2 and the secondary side 3 in a manner known per se, the principle of which is only shown here. In practice the heat exchange surface 12 has a much greater extension.

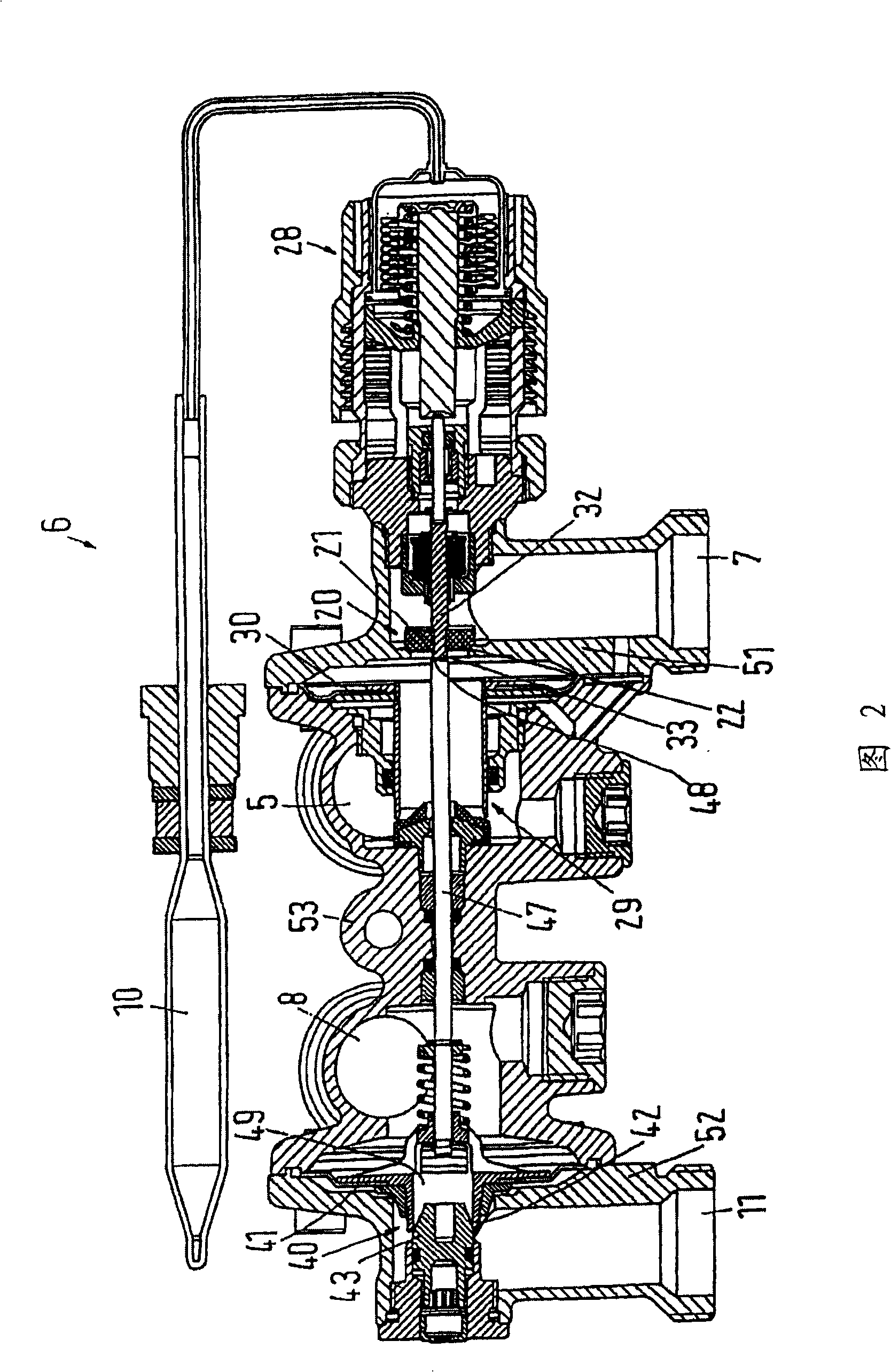

[0027] The valve de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com