Tridimensional allocation plan of aluminium foil mill

A technology of aluminum foil rolling mill and configuration scheme, applied in metal rolling and other directions, can solve the problems of waste of land, large area and high construction cost, and achieve the effect of reducing construction cost and maintenance cost, saving plant area and reducing the amount of earthwork.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

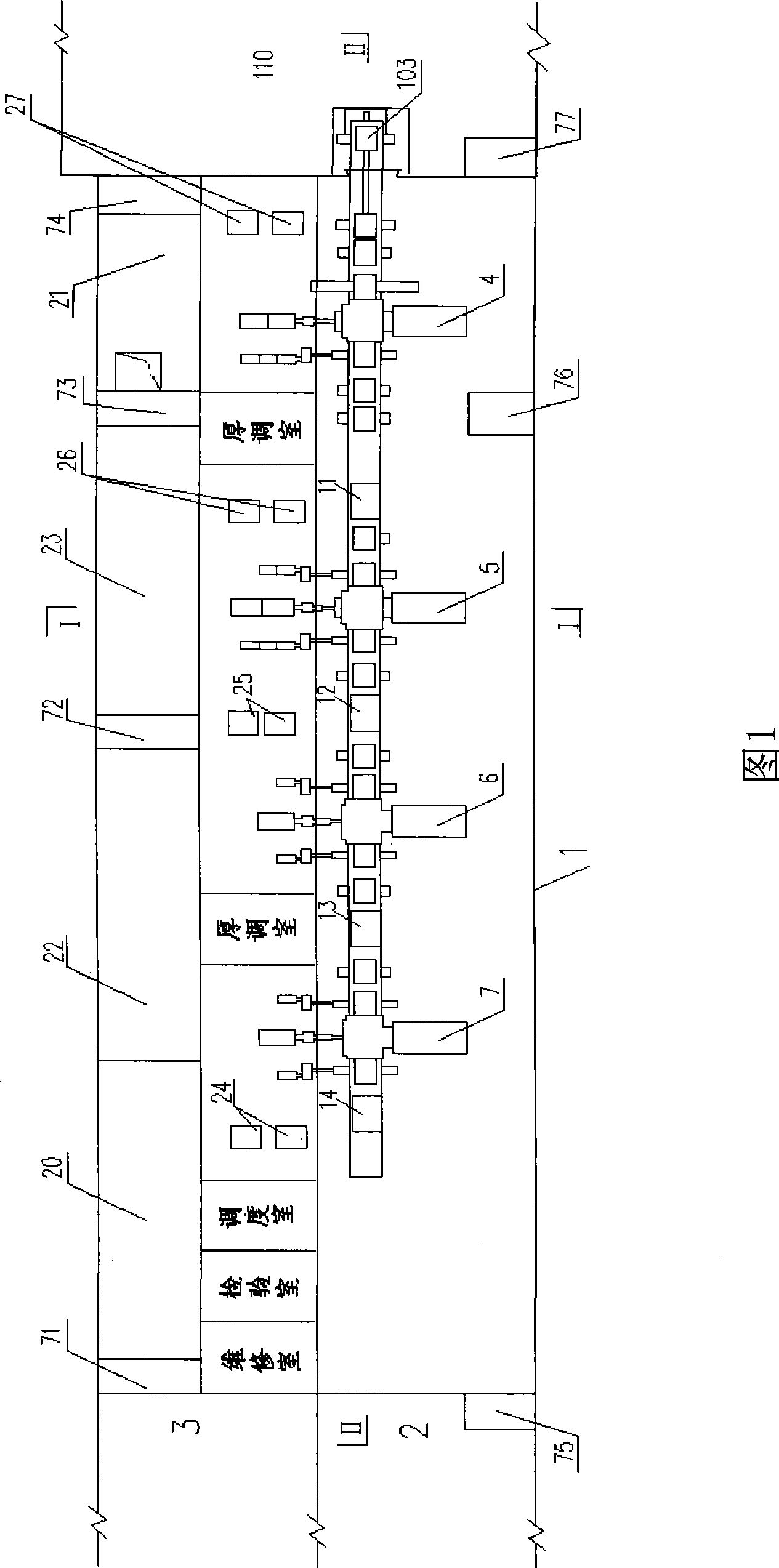

[0020] Rolling mill area 1 has a total length of 102m and a width of 36m. It is composed of rolling span 2 and rolling auxiliary span 3 with a width of 18m, both of which are two-story structures.

[0021] As shown in Figure 1, on the second-floor platform, from right to left, aluminum foil rough rolling mill 4, intermediate rolling mill 5, and two finishing mills 6, 7 are arranged in sequence. The electric control rooms 22 and 23 of the rolling mill, the hydraulic stations 24, 25, 26 and 27, and the oil mist purifiers 20 and 21 are placed in the rolling auxiliary span 3.

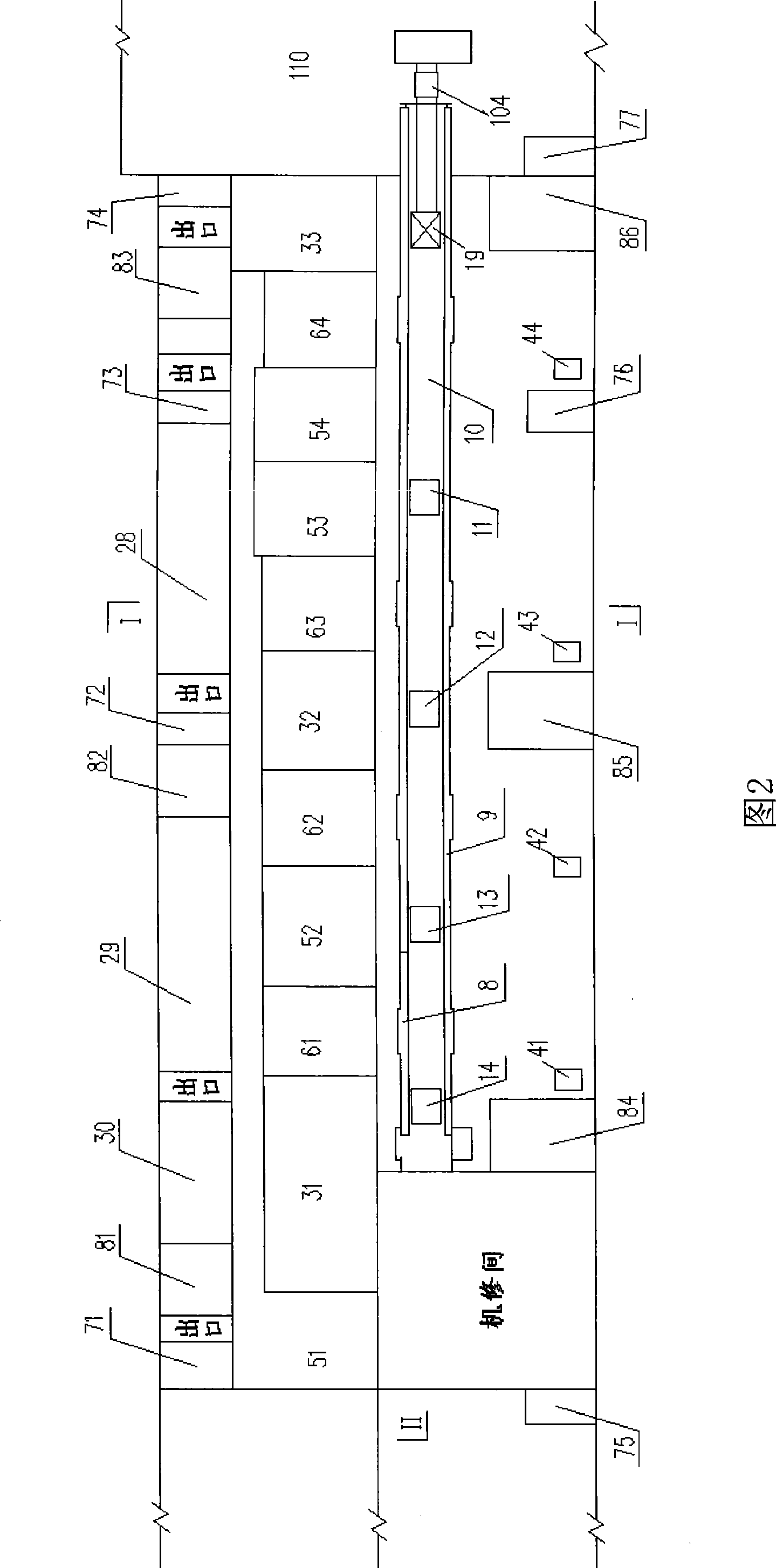

[0022] As shown in Figure 2, on the first floor plane, the transformer rooms 28 and 29 of the four rolling mills, the high-voltage distribution station 30, the process lubrication stations 31, 32 and 33, and the thin oil lubrication system stations 41, 42, 43, and 44, filter room 51, 52, 53 and 54, CO 2 Room 61, 62, 63, 64 and other auxiliary facilities.

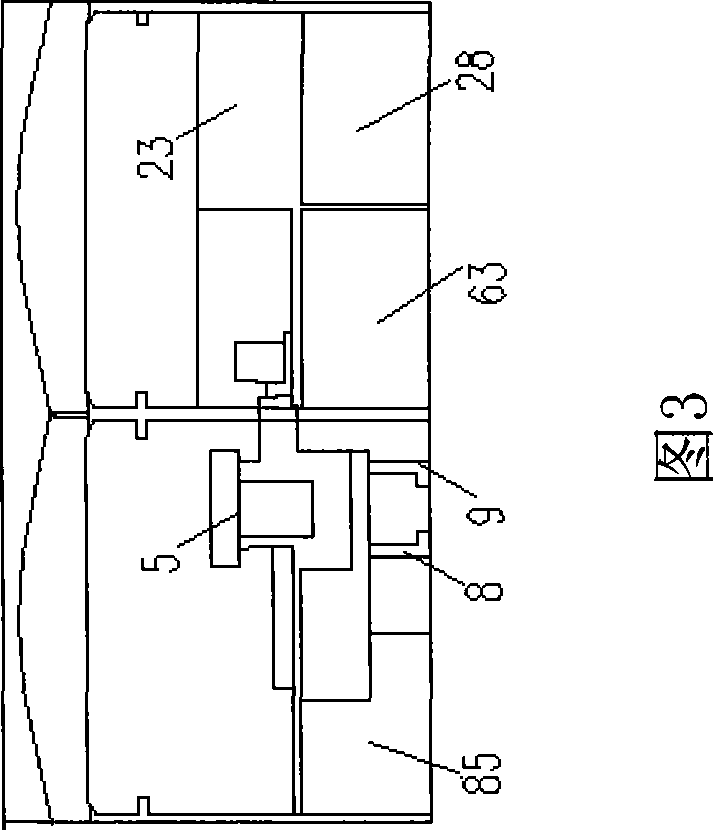

[0023] As shown in Figure 2 and Figure 3, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com