Ion exchange and recrystallization combined preparation apparatus and method for high-purity boric acid

An ion exchange and combined preparation technology is applied in the field of ion exchange recrystallization combined preparation device for high-purity boric acid, which can solve the problems of low electrolysis efficiency, long time required for electrolytic purification, high price, etc., and achieves convenient operation and high purification efficiency. Quantitative control is convenient and the device mechanism is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

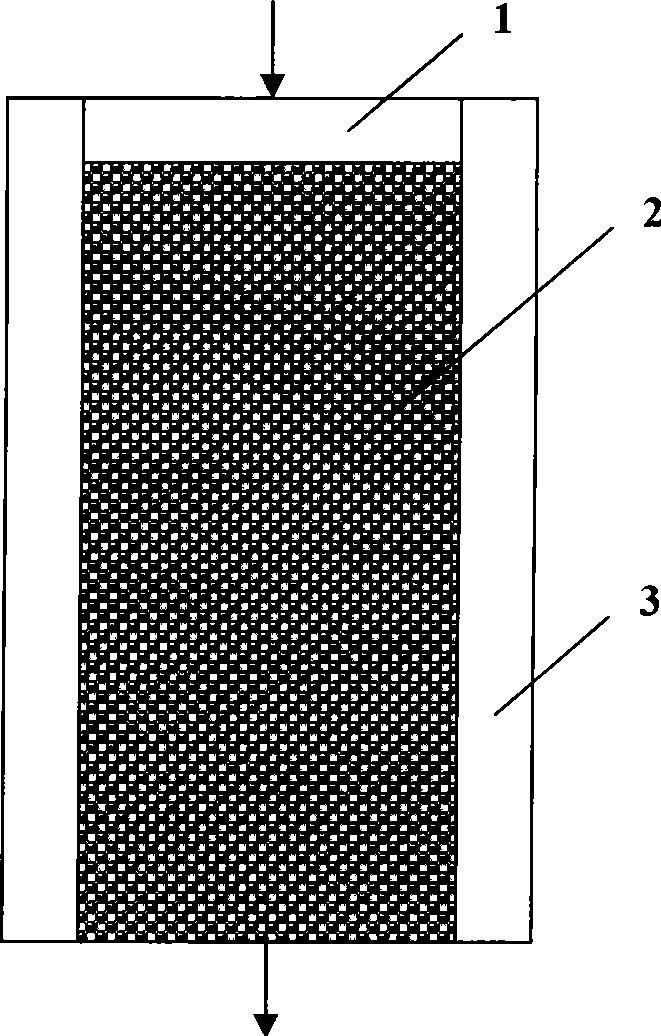

[0018] Embodiment 1: as figure 1 As shown, a high-purity boric acid ion exchange recrystallization combined preparation device includes an ion exchange column and a cooling tank. The ion exchange column includes an inner cavity 1 and a heating water jacket 3. The inner cavity 1 is placed in a strong acid type cation exchange Resin particles 2, the cooling tanks are a group of continuous cooling tanks, and the cooling tanks are provided with cooling devices. A combined preparation method of ion exchange and recrystallization of high-purity boric acid, the method is as follows: since the solubility of boric acid is very small at normal temperature, in order to increase the concentration of boric acid solution, 50 ° C boric acid solution is passed into an ion exchange column; the inner cavity of the ion exchange column is placed Strong-acid cation exchange resin particles remove metal ions in boric acid solution through ion exchange. The content of anion impurities in boric acid ...

Embodiment 2

[0019] Embodiment 2: It differs from Example 1 in that the number of ion-exchange columns is 2 connected in series, and the temperature of the ion-exchange columns is maintained at 55°C. When the room temperature was above 20°C, the boric acid solution was cooled by the cooling tank cooling device.

Embodiment 3

[0020] Embodiment 3: It differs from Embodiment 1 in that the heating device of the ion-exchange column is a heating wire, the number of ion-exchange columns is 4 connected in series, and the temperature of the ion-exchange column is maintained at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com