Anti-crack Construction Method for No.0 Block of Long-span Continuous Rigid Frame Bridge with High Pier

A construction method and rigid-frame bridge technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as easy cracks, hidden dangers, and great safety, and achieve the effect of preventing harmful cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

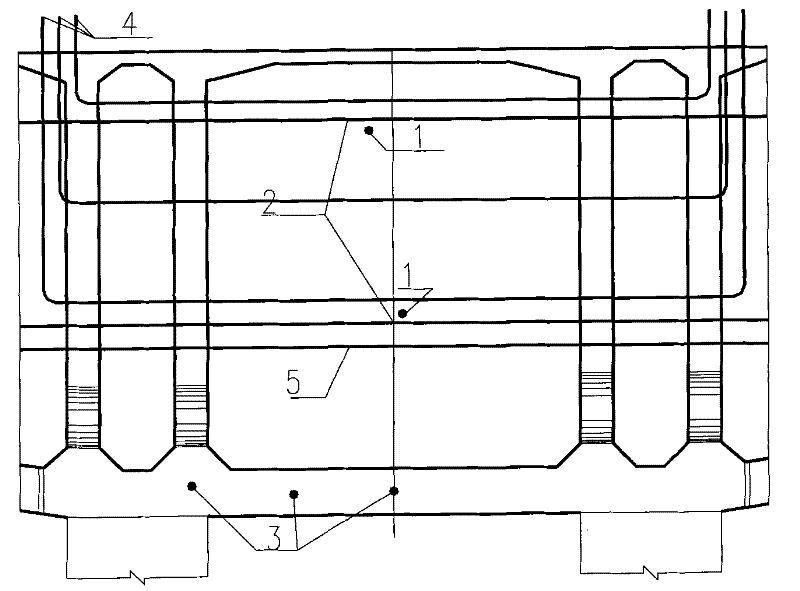

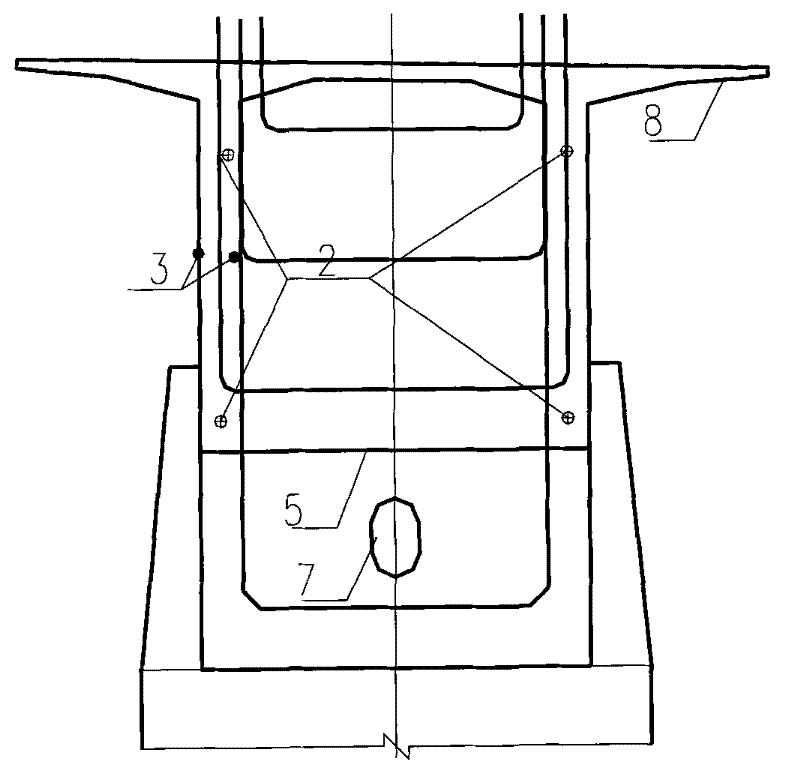

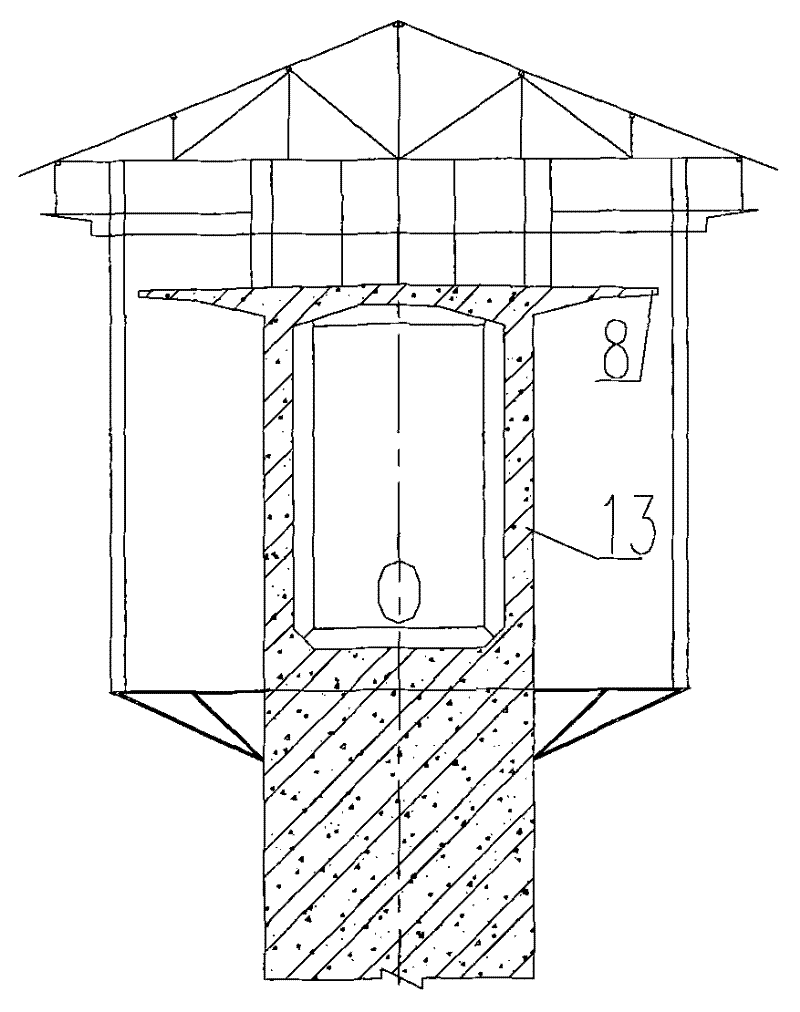

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 The anti-cracking construction method of No. 0 block of a high-pier long-span continuous rigid-frame bridge shown in the Image 6 Concrete is poured twice on the construction platform, the first pouring is to the compartment line 5 (0.3 to 0.6 times the web height), and the remaining part is pouring the second time. The age of the concrete on the second floor is controlled within 15 days, including the following step:

[0021] The first pour of concrete. a. Construction preparation, installation of bottom formwork, installation and fixation of outer formwork, installation and fixation of vertical prestressed tendons of web and diaphragm. b. Install cooling water pipes and temperature sensors. Cooling water pipe installation: Cooling water pipe 4 adopts Φ50*3.0mm thin-walled pipe, the distance between the horizontal bridges is 50cm, and a layer is arranged in the middle of the bottom plate. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com