Gravity supercharging water feeding machine

A technology of gravity and water delivery, which is applied in the fields of hydropower generation and other water energy applications, high-rise water delivery, water supply, and water storage. It can solve the problems of high suction water quality requirements, low suction height, and small flow range, etc., and achieve production costs. Low, enhanced pump pressure, no cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

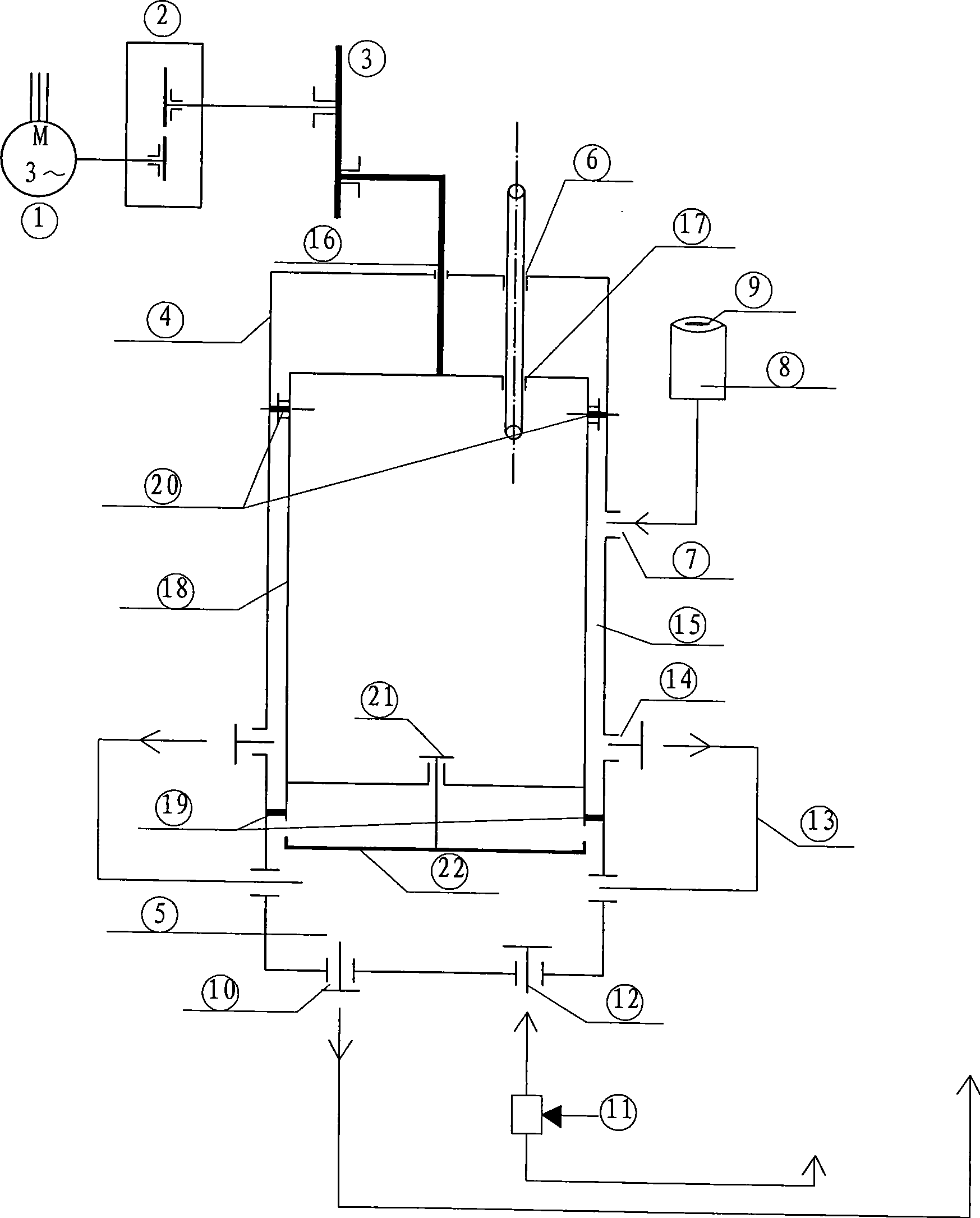

[0017] Embodiment: Gravity pressurized water feeder

[0018] refer to figure 1 : Gravity pressurized water feeder includes motor ①, transmission ②, crank wheel ③, pump cylinder ④, pump cylinder working room ⑤, pump cylinder water inlet ⑥, pump cylinder decontamination agent input port ⑦, pump cylinder decontamination agent storage Liquid cylinder ⑧, pump cylinder decontamination agent liquid storage cylinder port ⑨, drain valve ⑩, pump cylinder working room vacuum regulator (11), intake check valve (12), piston drain return pipe (13), piston drain Return check valve (14), pump clearance (15), piston assembly linkage (16), piston assembly water storage cylinder water inlet (17), water storage cylinder (18), piston ring (19), piston assembly guide Regulator (20), discharge valve axle frame (21), discharge valve (22) are made up of.

[0019] When the auxiliary motor drives the piston assembly to move upward, the volume of the working chamber of the pump cylinder expands and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com