Speed variator with variable flow impeller

A transmission and impeller technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of easy failure, high price, complex structure, etc. Efficiency, low manufacturing cost, good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

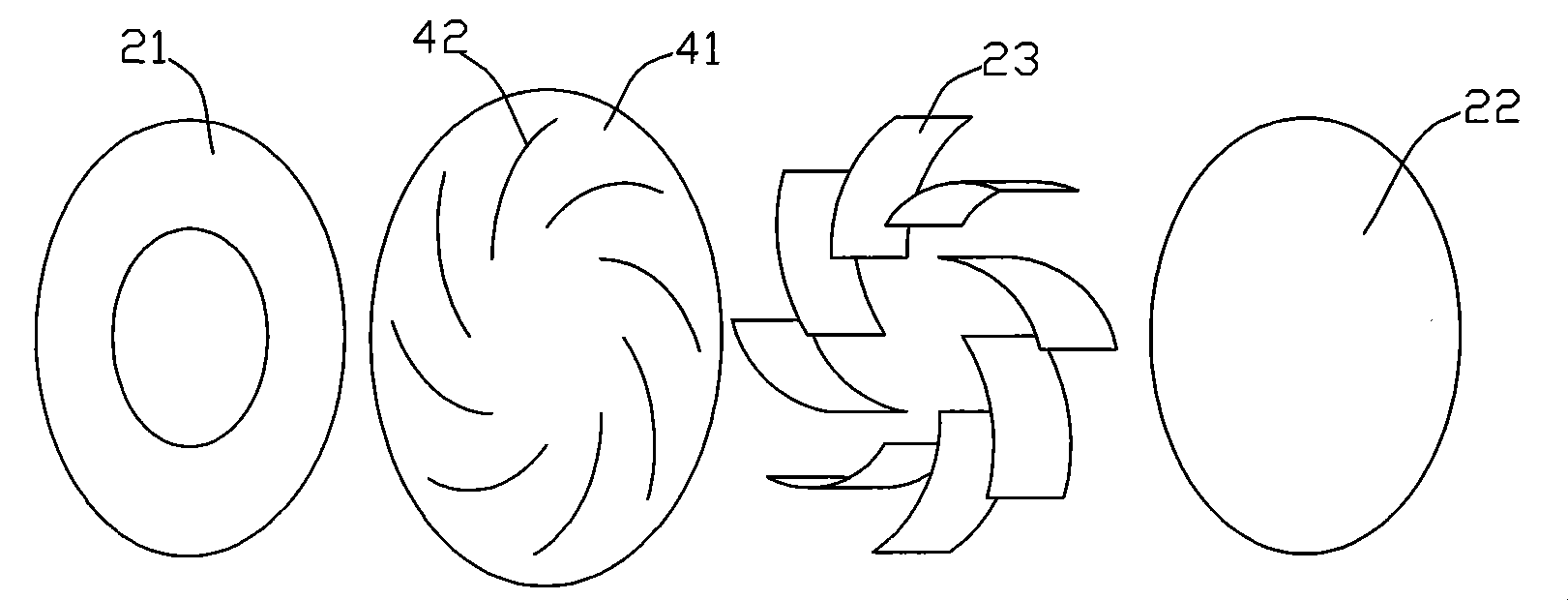

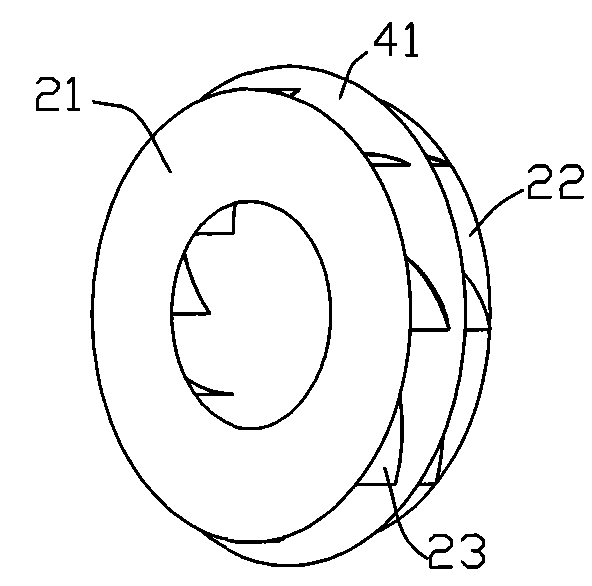

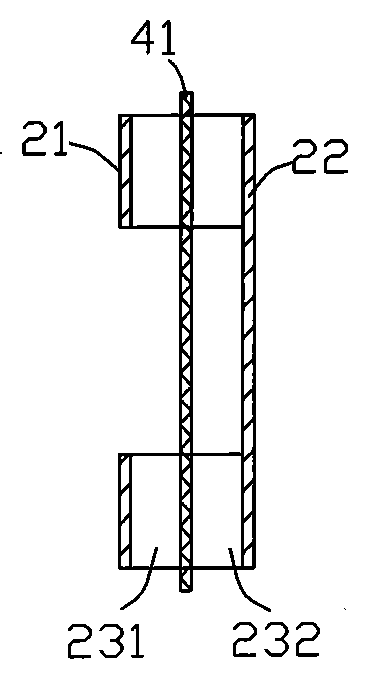

[0020] refer to Figures 1 to 3 , Figure 8 , Figure 9 , a transmission with a variable flow impeller, including a variable flow impeller, the impeller includes a front disk 21, a rear disk 22 and a blade 23 installed in the pump housing 1, the rear disk 22 is installed on the rotating shaft 31, and the blade 23 is covered A restrictor is provided, and the restrictor includes a partition 41, a slot 42 adapted to the thickness and shape of the blade 23 is provided on the partition 41, the blade 23 penetrates into the slot 42, and the partition 41 is connected with An adjustment device, the partition 41 can move forward and backward in the axial direction of the blade 23 driven by the adjustment device, and the partition 41 divides the blade 23 into an effective working area 231 and an ineffective working area 232 .

[0021] For a centrifugal impeller, if its diameter, blade length, curvature, thickness and other parameters are the same, the width of the blade determines the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com