Method and apparatus for detecting stress field of hoister roller

A detection method and hoist technology, applied in the direction of measuring device, measuring force, transmission system, etc., can solve the problems of inconvenient installation of sensors, inconvenient installation and maintenance of sensors, and difficult installation, etc., and achieve high communication speed and communication reliability. Power supply problems, the effect of convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

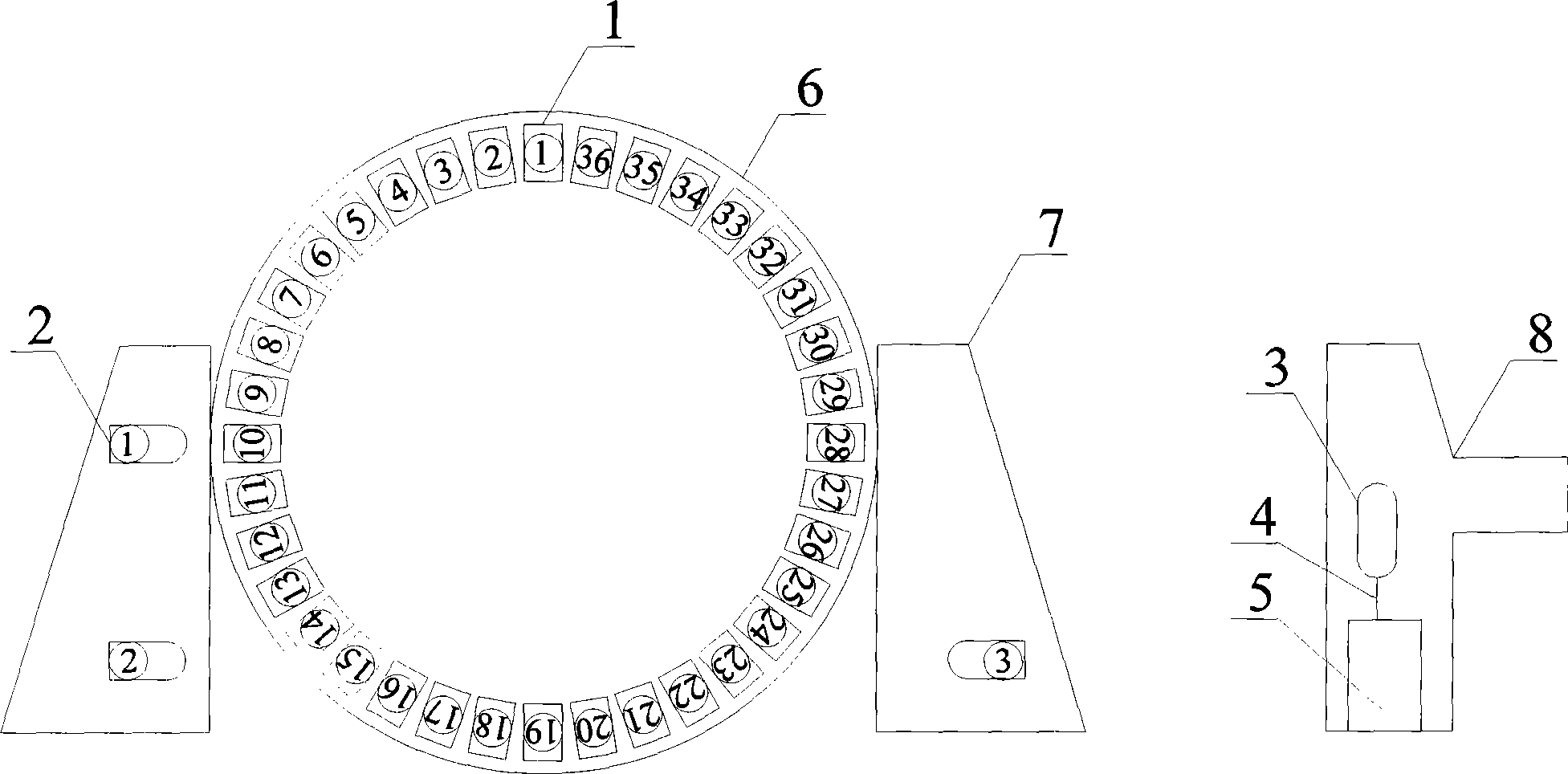

[0016] Embodiment 1: The device of the present invention includes a hoist drum, a brake seat, a stress wireless sensor node 1, an anchor node 2, a convergence node 3, a USB interface 4 and an industrial computer 5, and the brake seat is located on the outside of the hoist drum , the stress wireless sensor node is fixed on the hoist roller, the anchor node is fixed on the brake seat, the converging node is fixed on the shell of the hoist console, and the converging node is connected to the industrial computer through the USB interface.

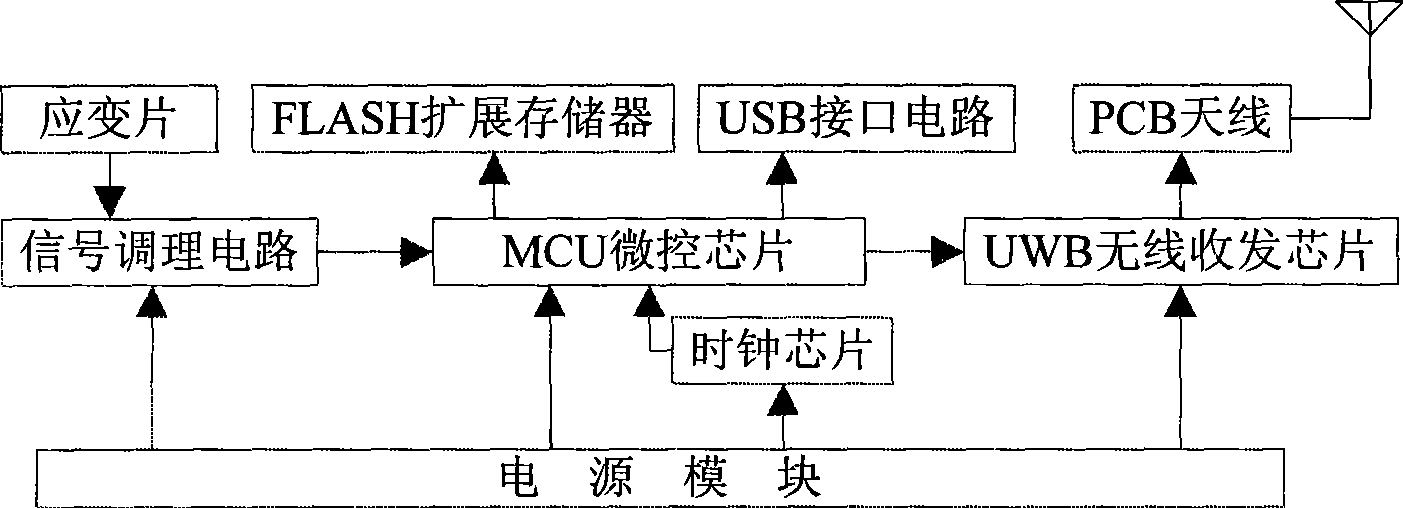

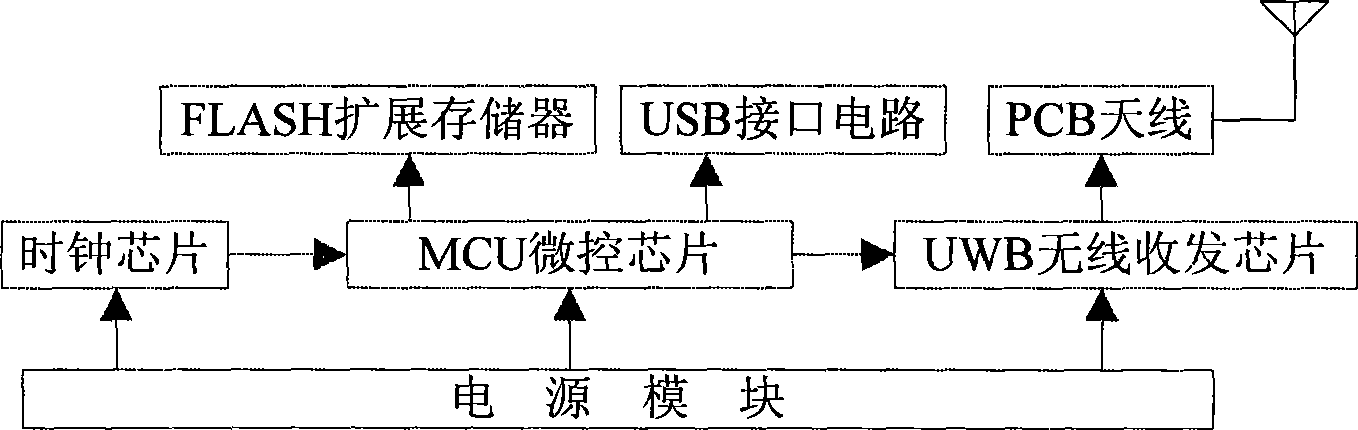

[0017] The stress wireless sensor node is composed of strain gauge, signal conditioning circuit, MCU micro-control chip, UWB wireless transceiver chip, FLASH expansion memory, USB interface circuit, PCB antenna, clock chip and power module, and the strain gauge is connected to the signal conditioning circuit , the output end of the MCU micro-control chip is connected to the UWB wireless transceiver chip, FLASH expansion memory and USB interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com