High sensitivity nondestructive detection method of array type flexible vortex flow probe and probe apparatus thereof

An eddy current probe, high-sensitivity technology, used in measuring devices, electrical devices, instruments, etc., can solve the problems of low resolution of probes, reduced flexibility, insufficient individual inductance of coil units, etc., to achieve high sensitivity without loss. The effect of detection, improved sensitivity, and increased individual inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The high-sensitivity non-destructive testing method of the array type flexible eddy current probe of the present invention is to place a back pad made of ferrite and the like on the back of the conventional array type flexible eddy current probe relative to the detection side, and adopt the conventional The eddy current testing method performs eddy current testing on the components; the back pad completely covers all the small coils in the conventional array flexible eddy current probe, and increases the individual inductance of each coil unit during testing.

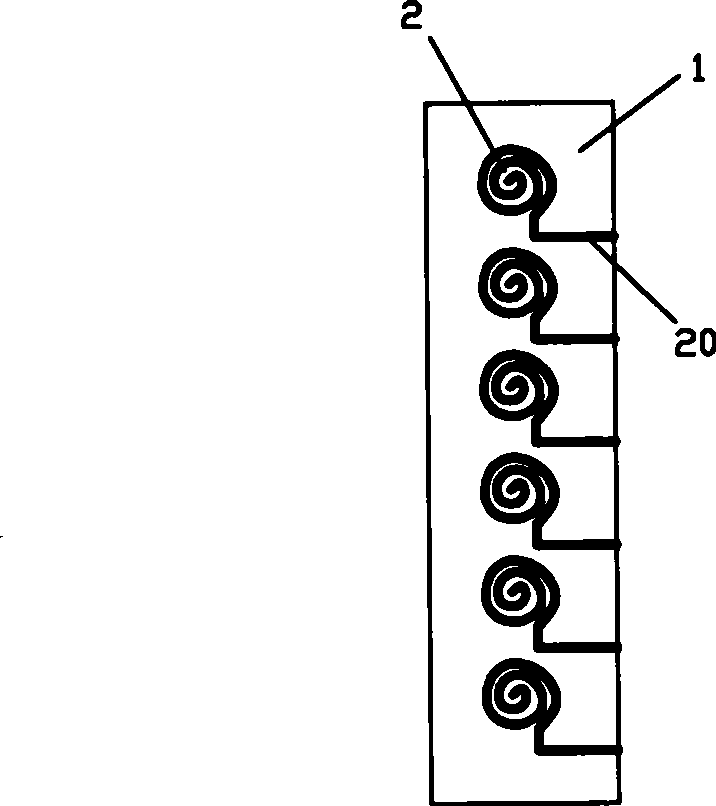

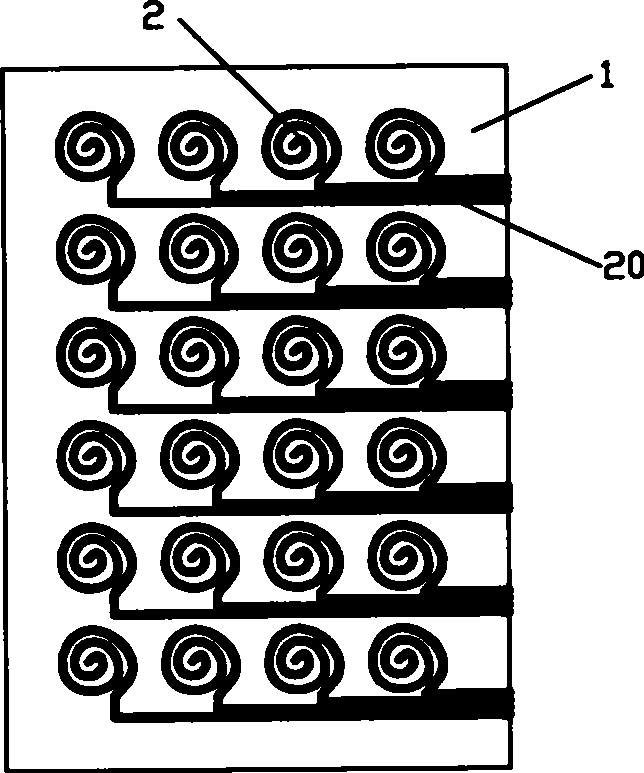

[0031] Referring to the accompanying drawings, the high-sensitivity array flexible eddy current probe device of the present invention includes:

[0032] A flexible circuit board 1, the flexible circuit board 1 is provided with a plurality of spiral printed coils 2 arranged in a certain array; each printed coil is provided with a printed lead 20 to connect with an external processing circuit;

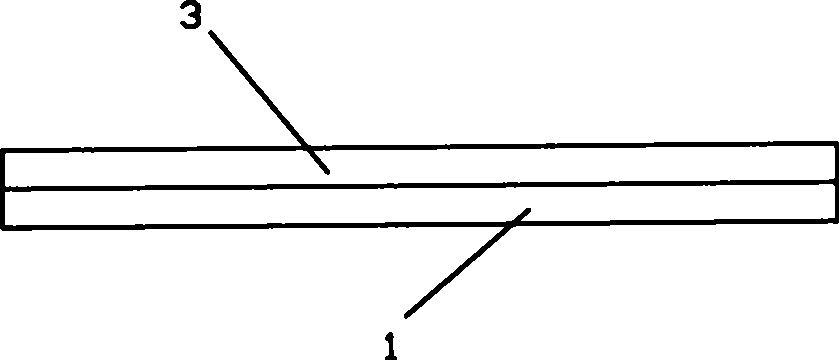

[0033] A back pad 3 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com