RFID interface controller of discrete manufacturing business machining assembly line

An interface controller and assembly line technology, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of different interface methods of RFID readers and difficult application of RFID technology, and achieve the effect of facilitating system maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

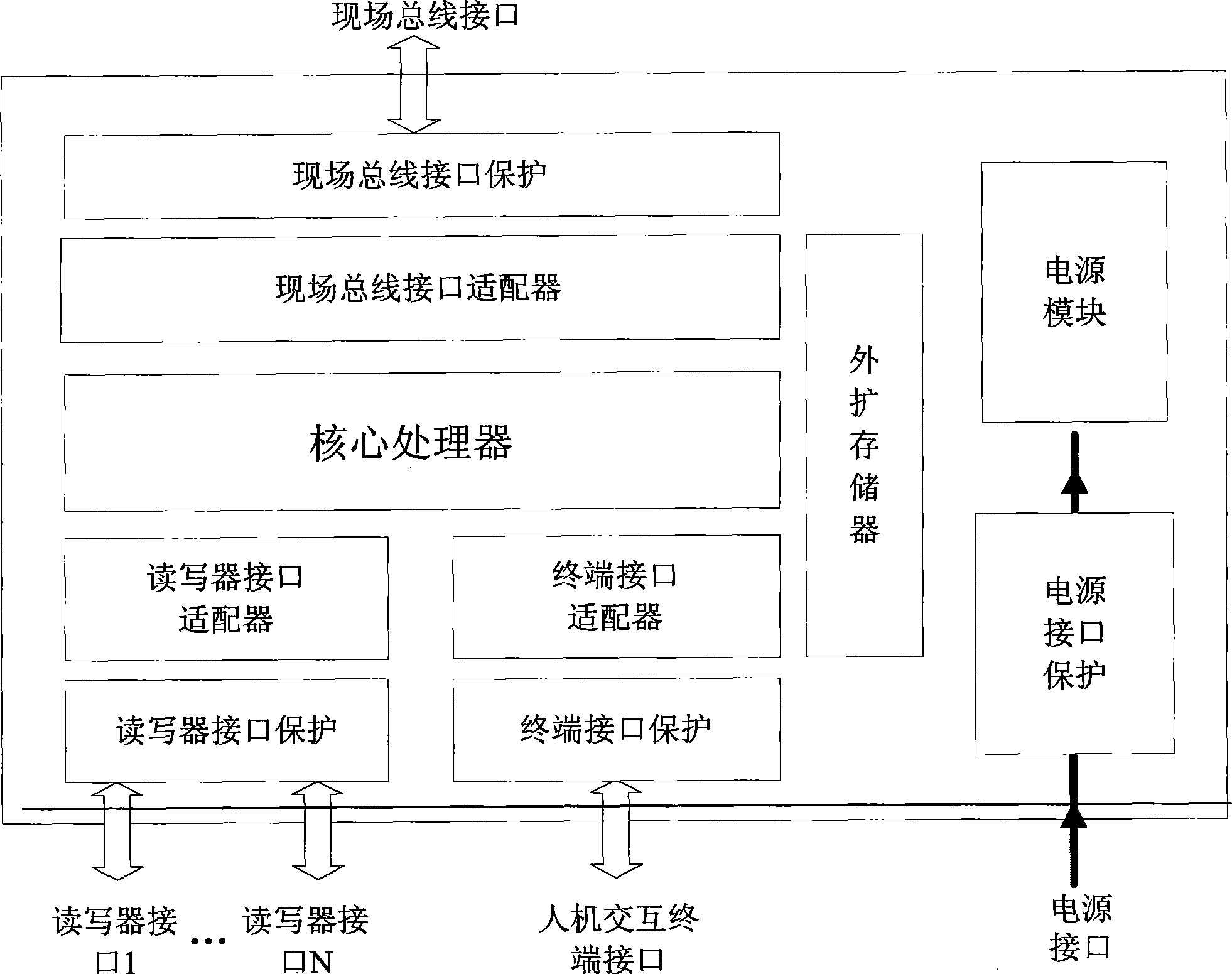

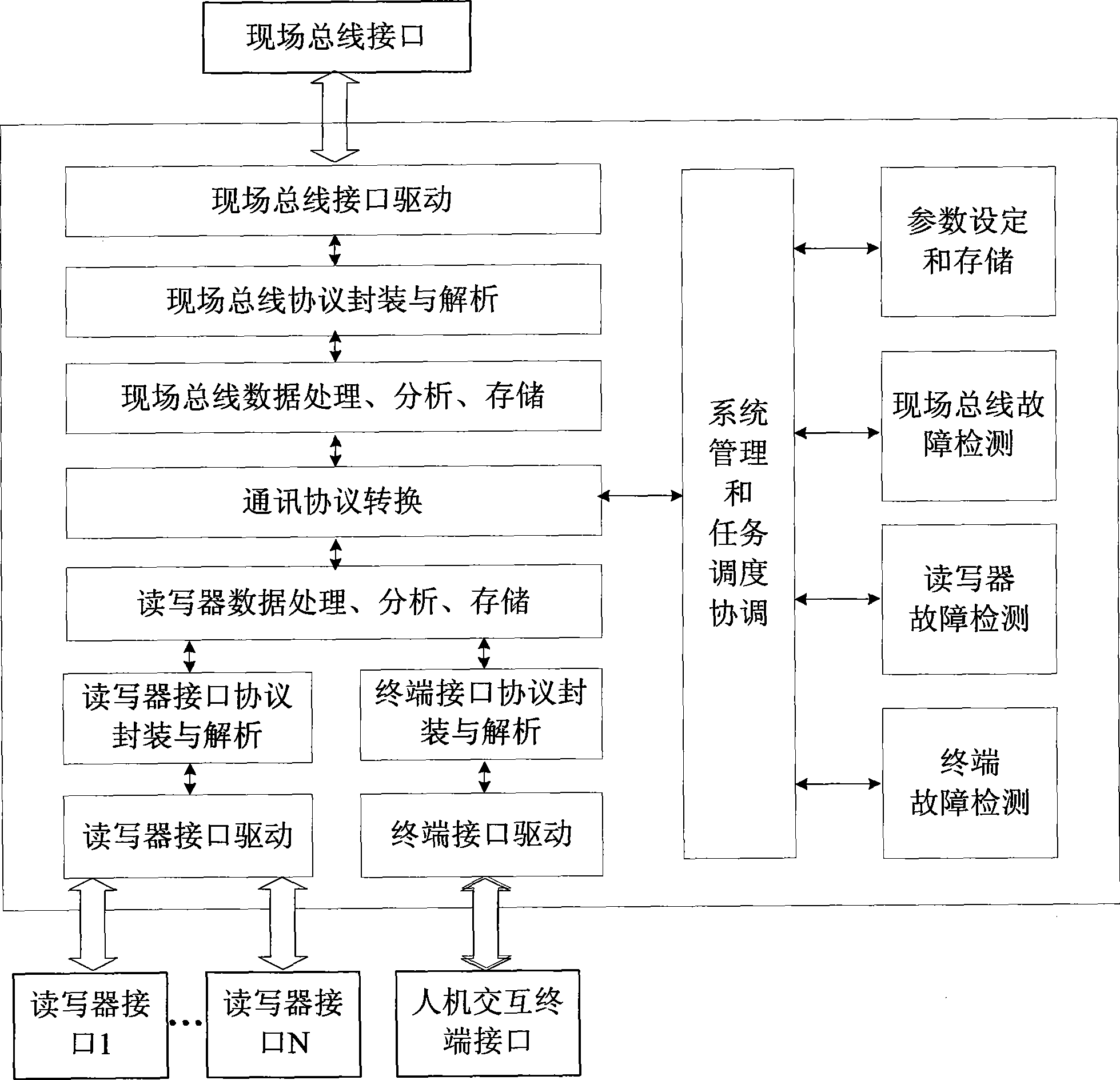

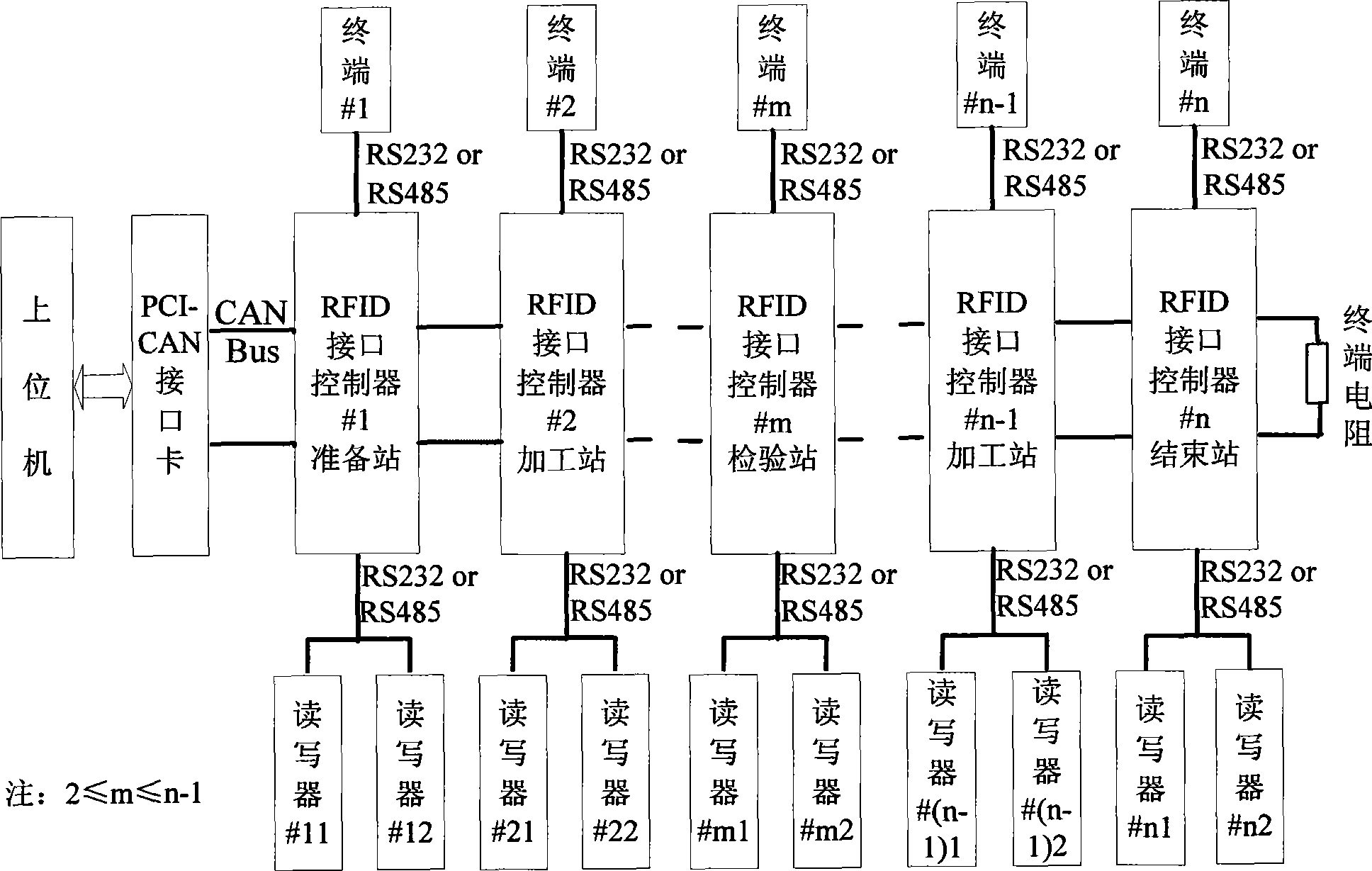

[0029] Such as figure 1 As shown, an RFID interface controller for a discrete manufacturing process line is a device with hardware middleware functions between the host computer software and the RFID reader, including an RFID for power supply and communication between the controller and the external reader. Reader interface; human-computer interaction terminal interface for power supply and communication between the controller and the external terminal; fieldbus interface for communication between the controller and the host computer; power-down storage for the controller setting parameters The external expansion memory; the processor that can realize the driver of each communication interface, protocol encapsulation, analysis and conversion, task scheduling and coordination; and the power supply and protection circuit for reliable power supply for the processor, communication interface and peripherals. The RFID reader interface adopts RS232 interface or RS485 interface. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com