Hybrid process using ion exchange resins in the selective recovery of nickel and cobalt from leaching effluents

An ion exchange resin, ion exchange technology, applied in the direction of ion exchange, cation exchange, organic cation exchanger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that a resin (methylaminopyridine group) can be found on the market which is capable of adsorbing nickel in extremely acidic conditions and in the presence of high concentrations of impurities, although it is very expensive for most nickel projects. high. For this resin, none of the procedures that are recommended and suggested in this text apply, since no pretreatment, or even removal of impurities, nor increase of pH is required, so there are no consequences resulting from the preceding steps. inconvenient.

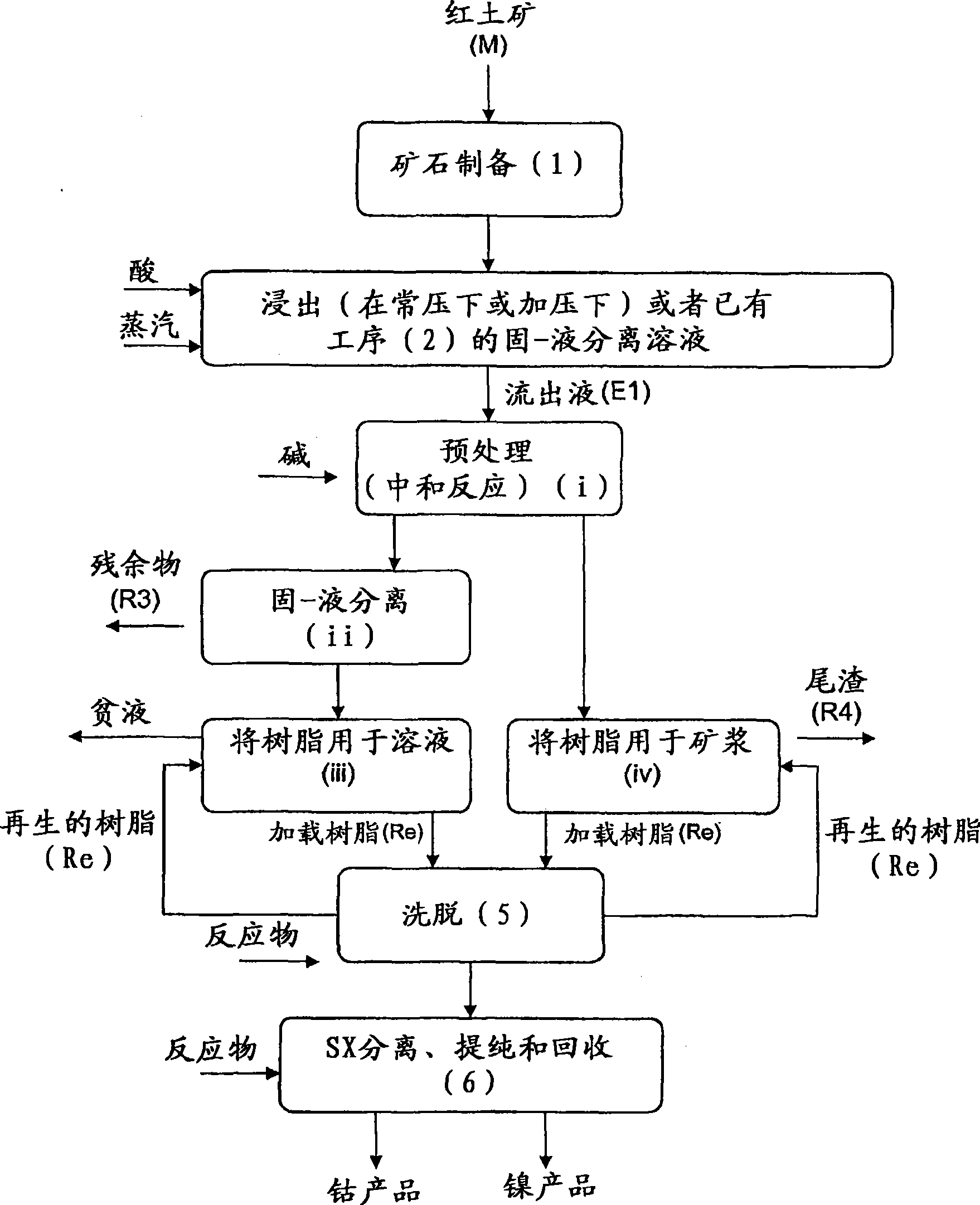

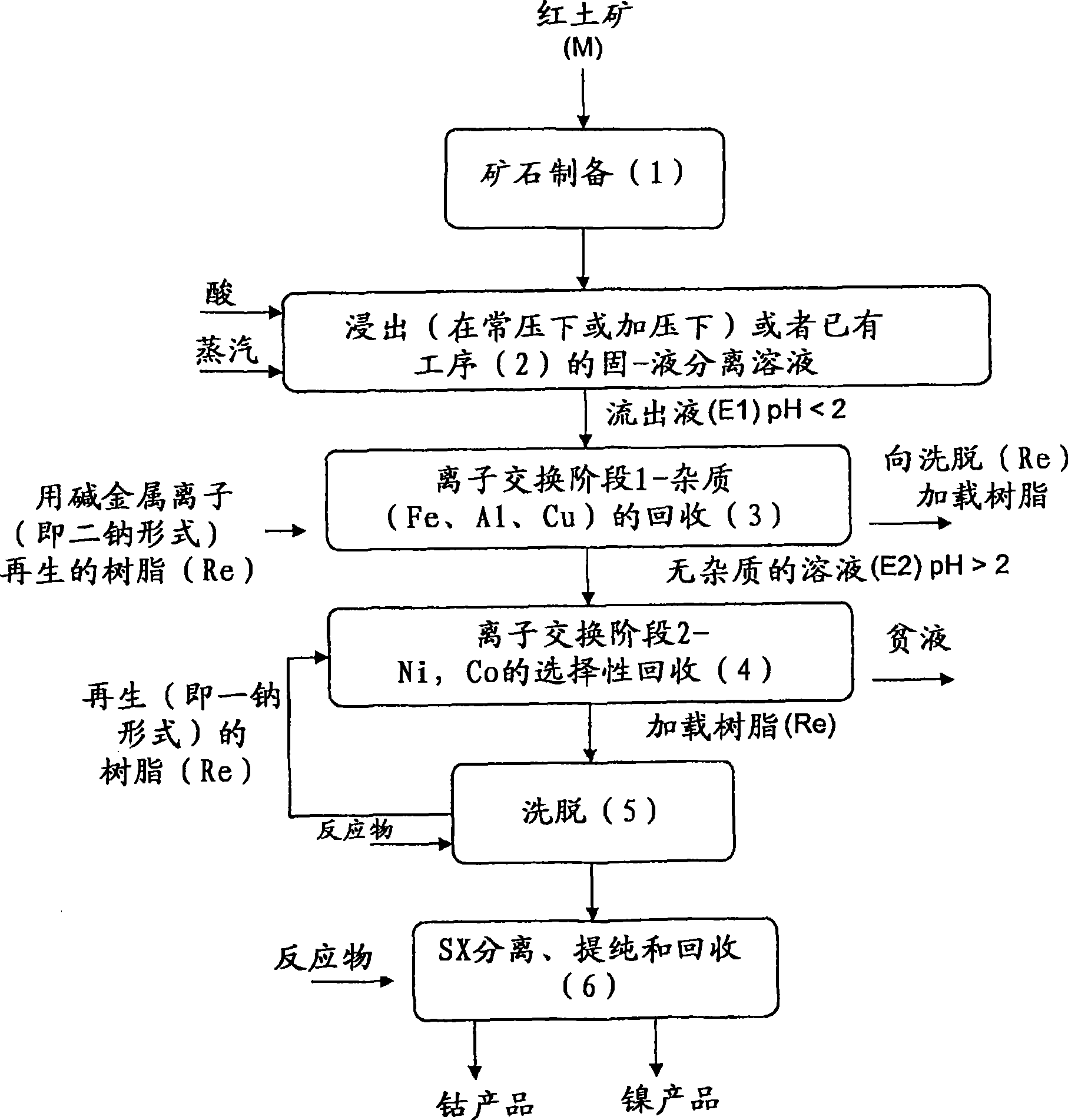

[0034] According to these figures, the proposed technical solution is to omit the pretreatment (neutralization) step of the pulp in order to increase the pH value and precipitate impurities such as iron, aluminum and copper, thereby preventing the loss of nickel in the precipitation through co-precipitation and preventing Solid-liquid separation of the pulp produced in the pretreatment step is required. This approach involves a two-step compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com