Five-axle automatic sequence cycling production line

An automatic sequence, production line technology, applied in the field of brush production, to achieve the effect of improving work efficiency, work efficiency, quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below with reference to the accompanying drawings, but they do not constitute a limitation of the present invention, but are merely examples. At the same time, the advantages of the present invention will become clearer and easier to understand by illustrating the advantages.

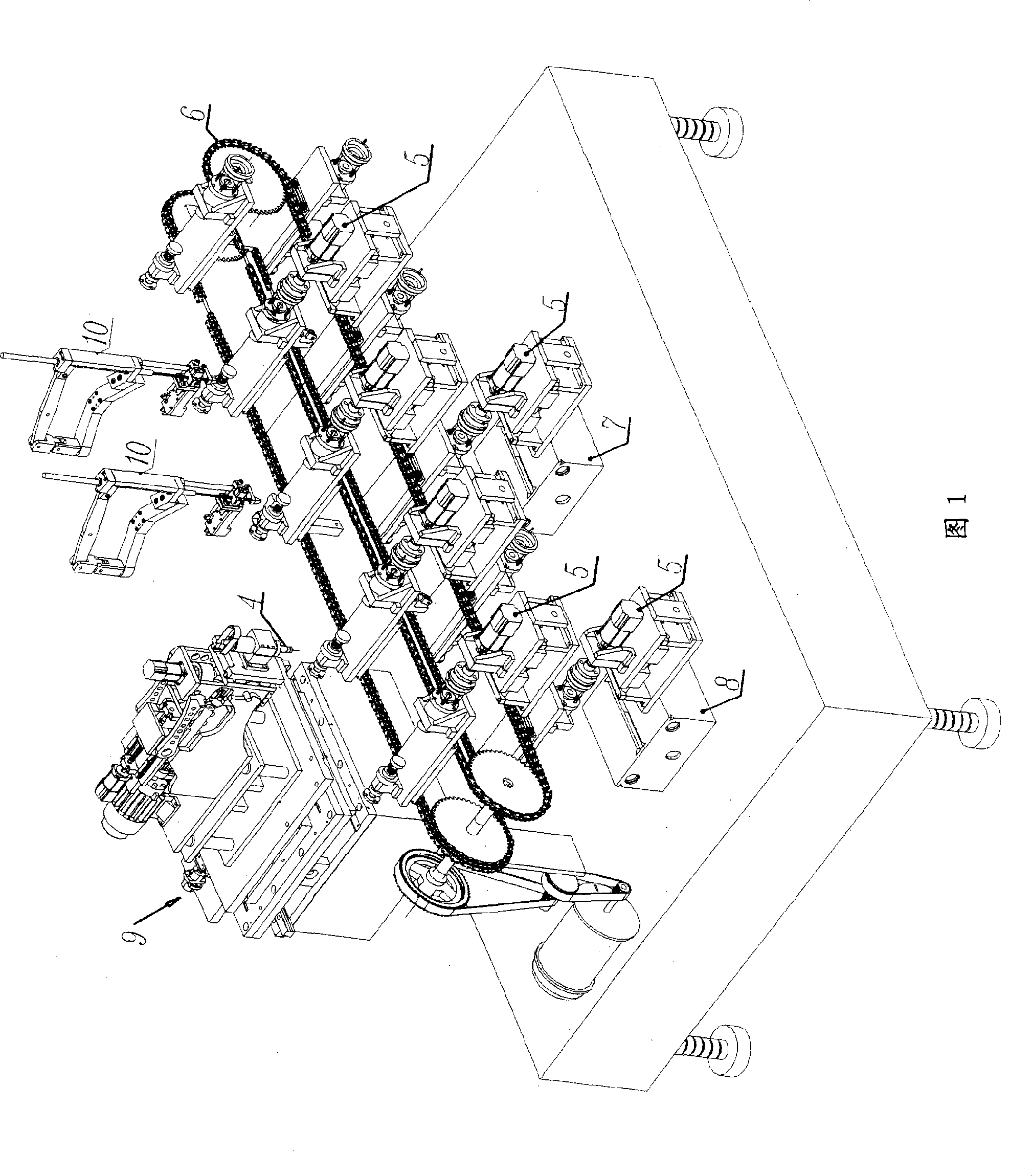

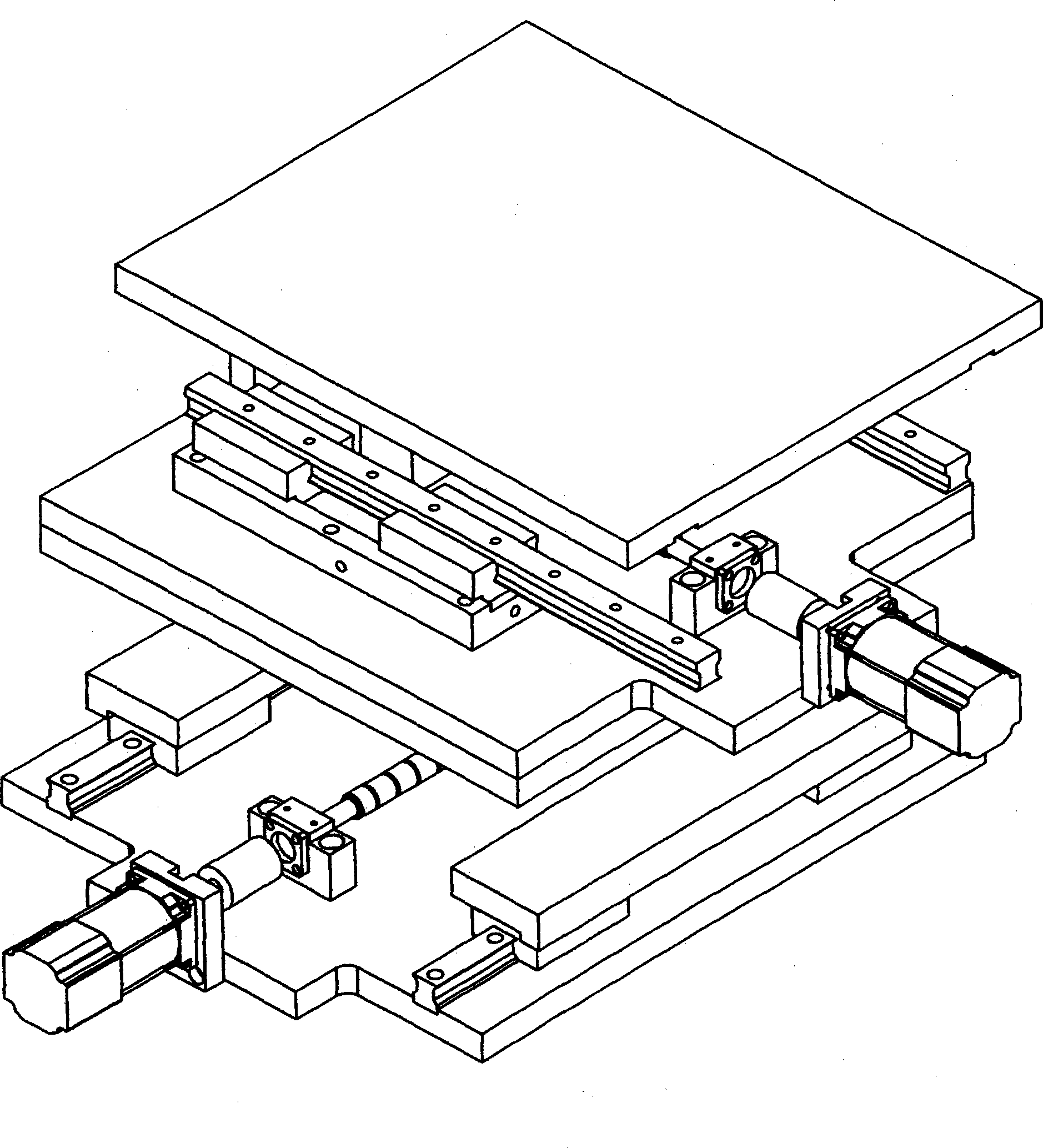

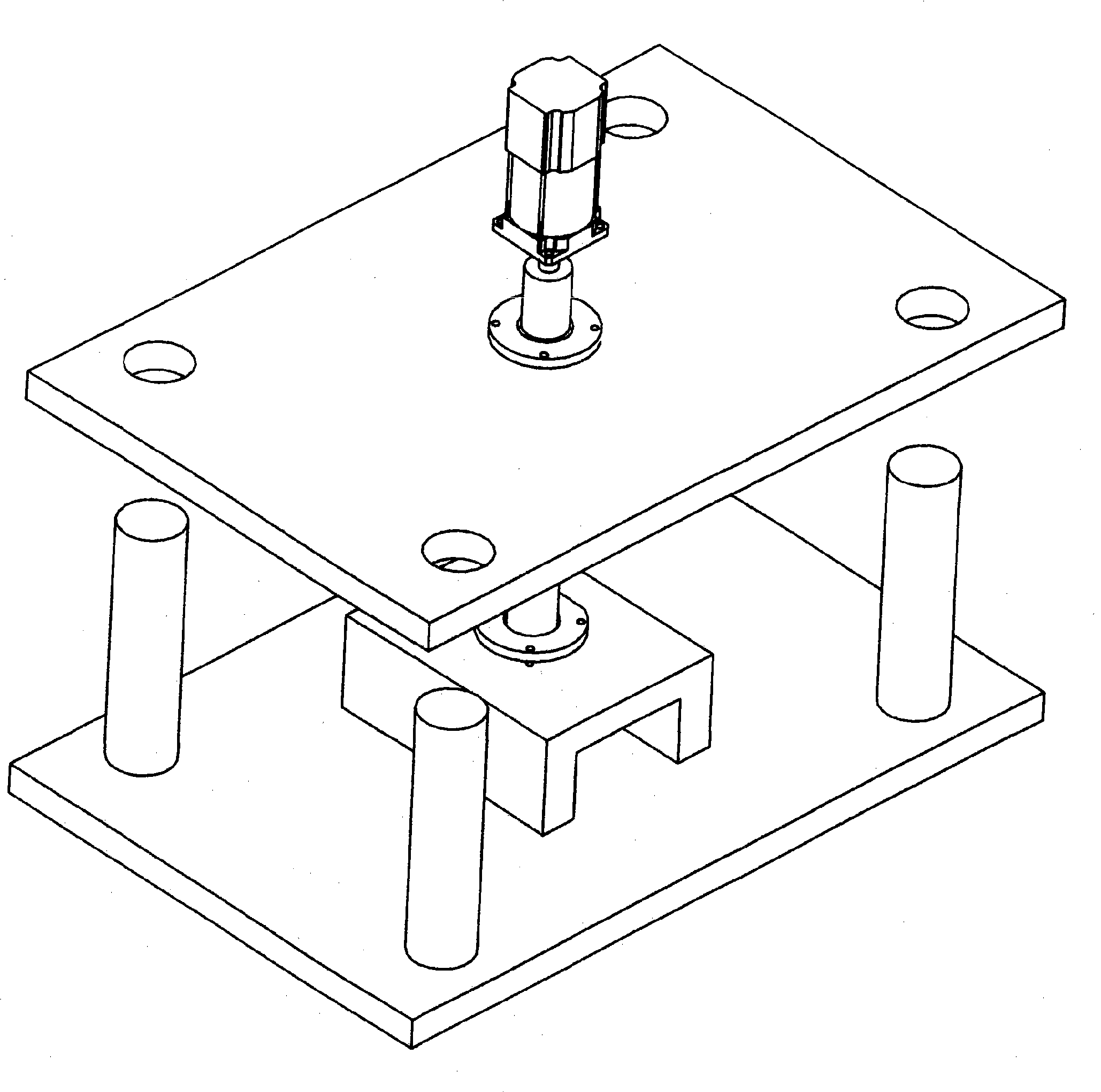

[0022] Referring to the accompanying drawings, it can be known that the five-axis automatic sequential circulation production line of the present invention comprises a body 1, a conveying device 6 for the sequential circulation production line, a drilling machine 4 and a hair planting machine 10 located at the upper end of the conveying device 6, and located at the lower end of the conveying device 6. The shearing machine 7 and the hair grinding machine 8, it also includes a clamp table 5 that can be self-locking and can be circularly moved to match each shearing machine 7, hair grinding machine 8, drilling machine 4 and hair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com