Air-bearing support workstation design method

A design method and workbench technology, applied in metal processing equipment, manufacturing tools, metal processing mechanical parts, etc., to achieve the effect of low implementation requirements, saving resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

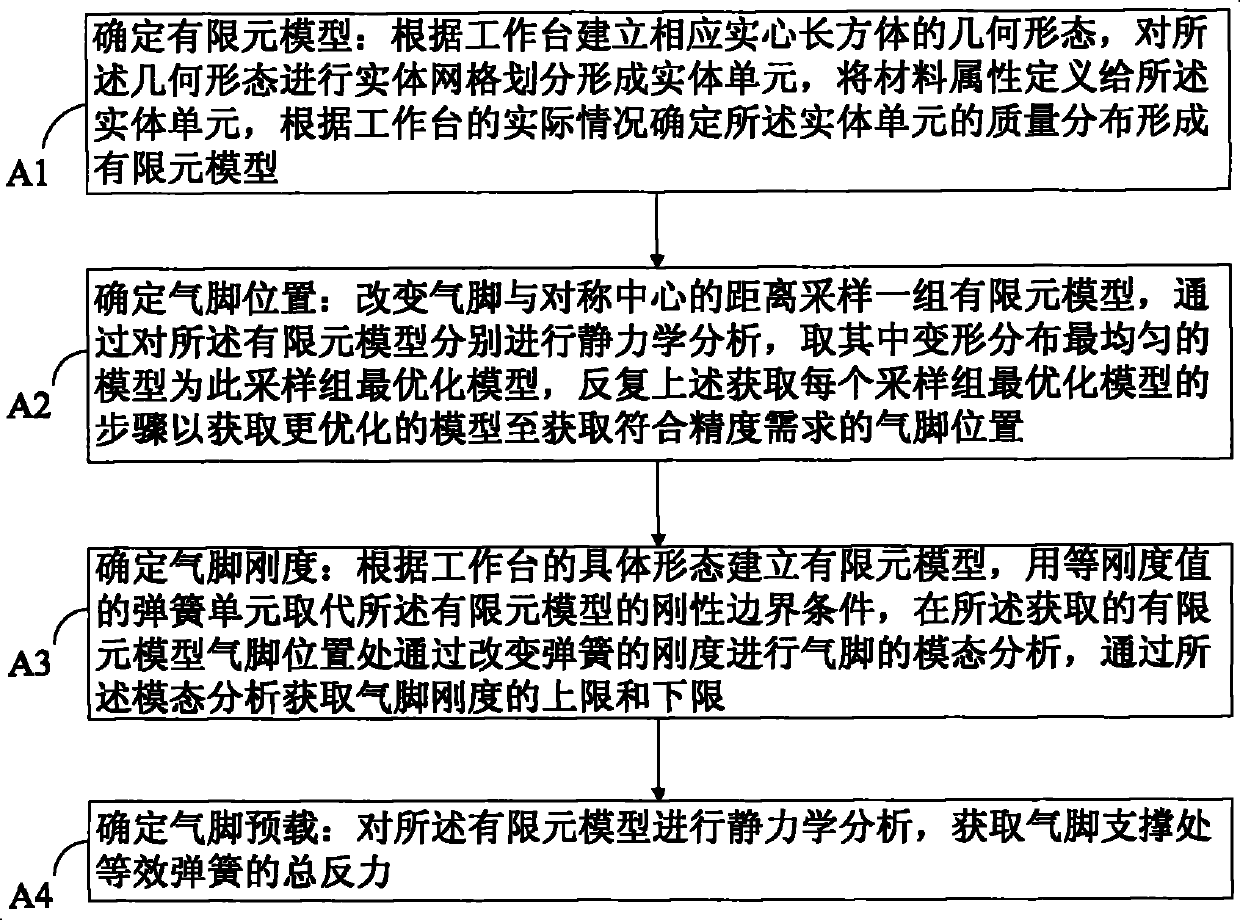

[0039] Such as figure 2 As shown, it is a flow chart of the design method of the air foot support workbench of the present invention. The method proposed by the present invention can be implemented in the entire design process of the large workbench, which not only depends on the design of the workbench but also affects the design of the workbench. Design, can be divided into two parts.

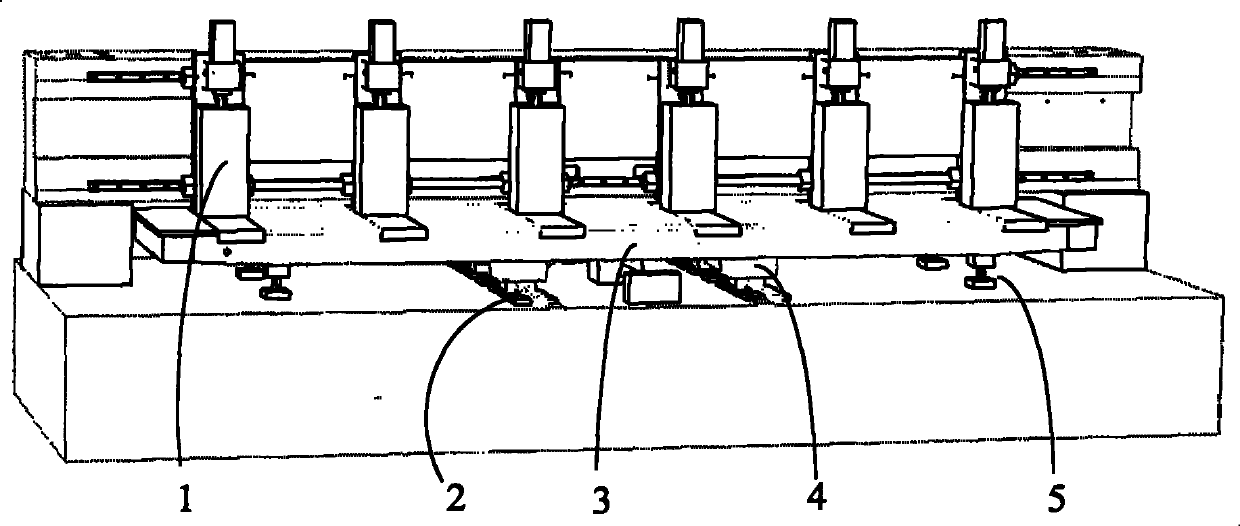

[0040] The first part is in the conceptual design stage. The internal frame structure and other details of the workbench have not yet been determined, but only the size (length, width and height), weight (total mass and concentrated mass distribution) and materials of the workbench have been initially planned. Time. At this time, it is necessary to determine the position of the guide rail slider and the air foot support before it is possible to design the specific shape inside the workbench. Relatively speaking, the position of the guide rail slider is easy to determine according to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com