Transformer and combined construction thereof

A technology of transformers and structures, applied in the direction of transformers, fixed transformers, transformer/inductor coils/windings/connections, etc., can solve the problems of poor transformer efficiency, distance from the magnetic circuit iron core, and copper sheet displacement, etc. Efficiency, area reduction, and leakage inductance reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

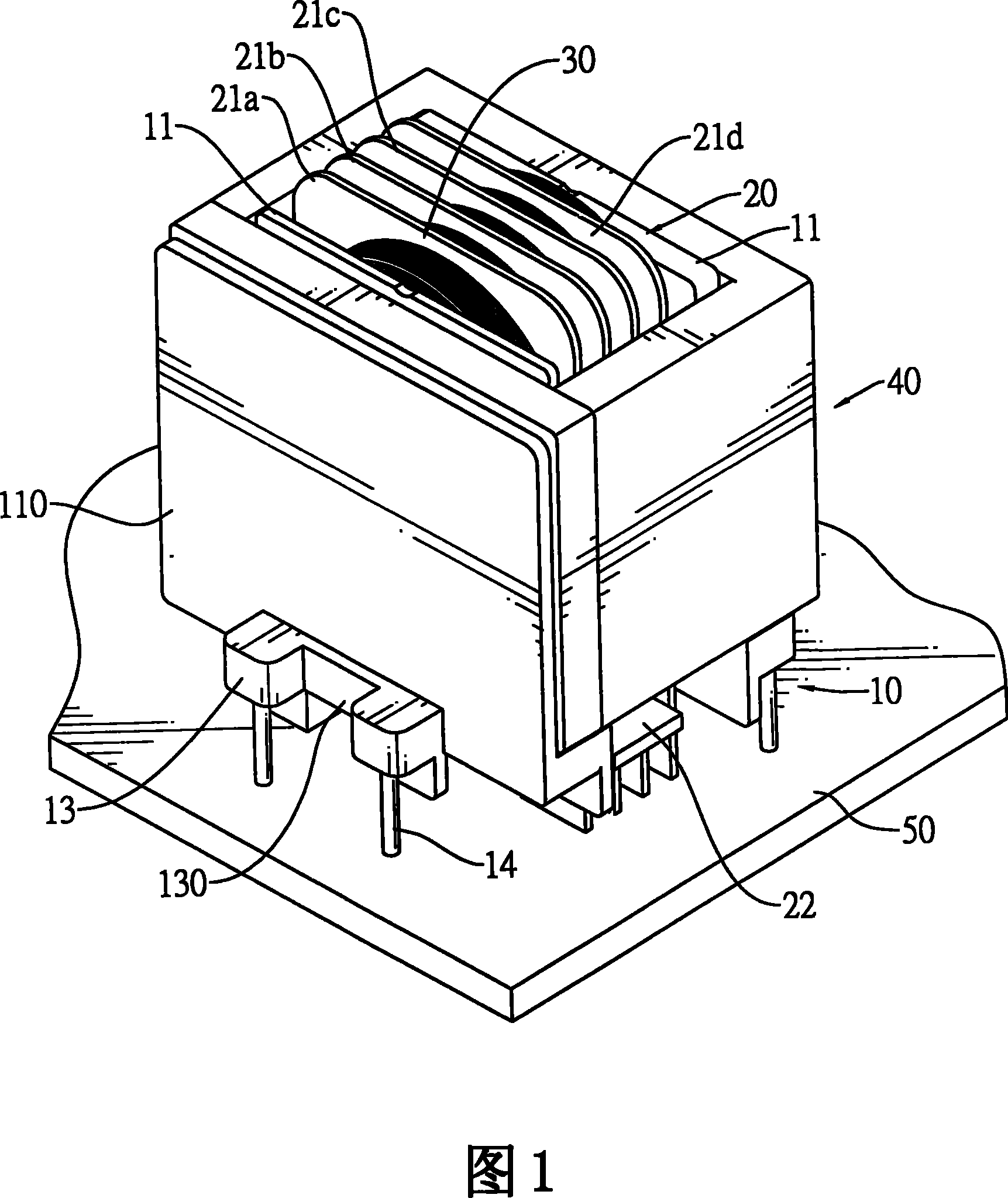

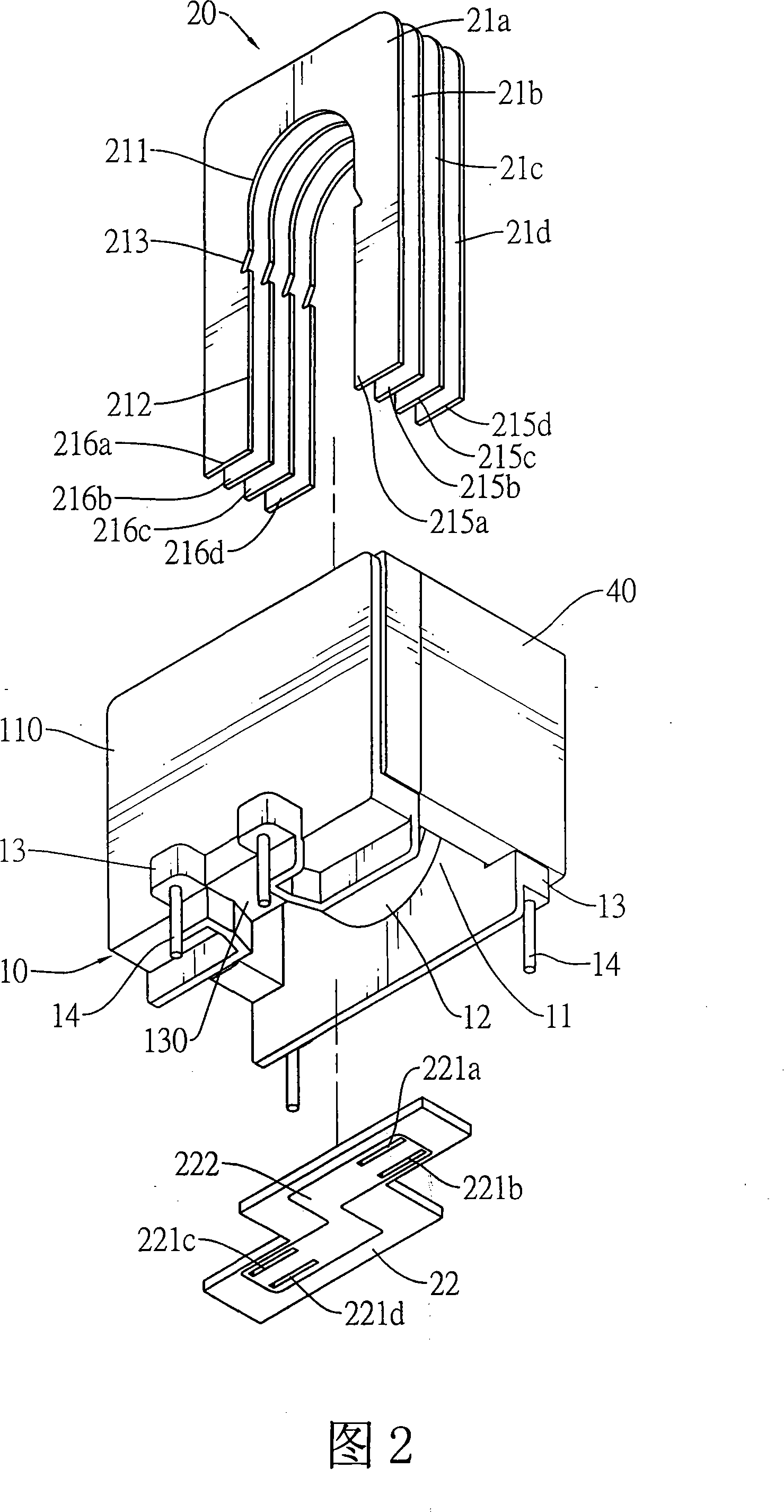

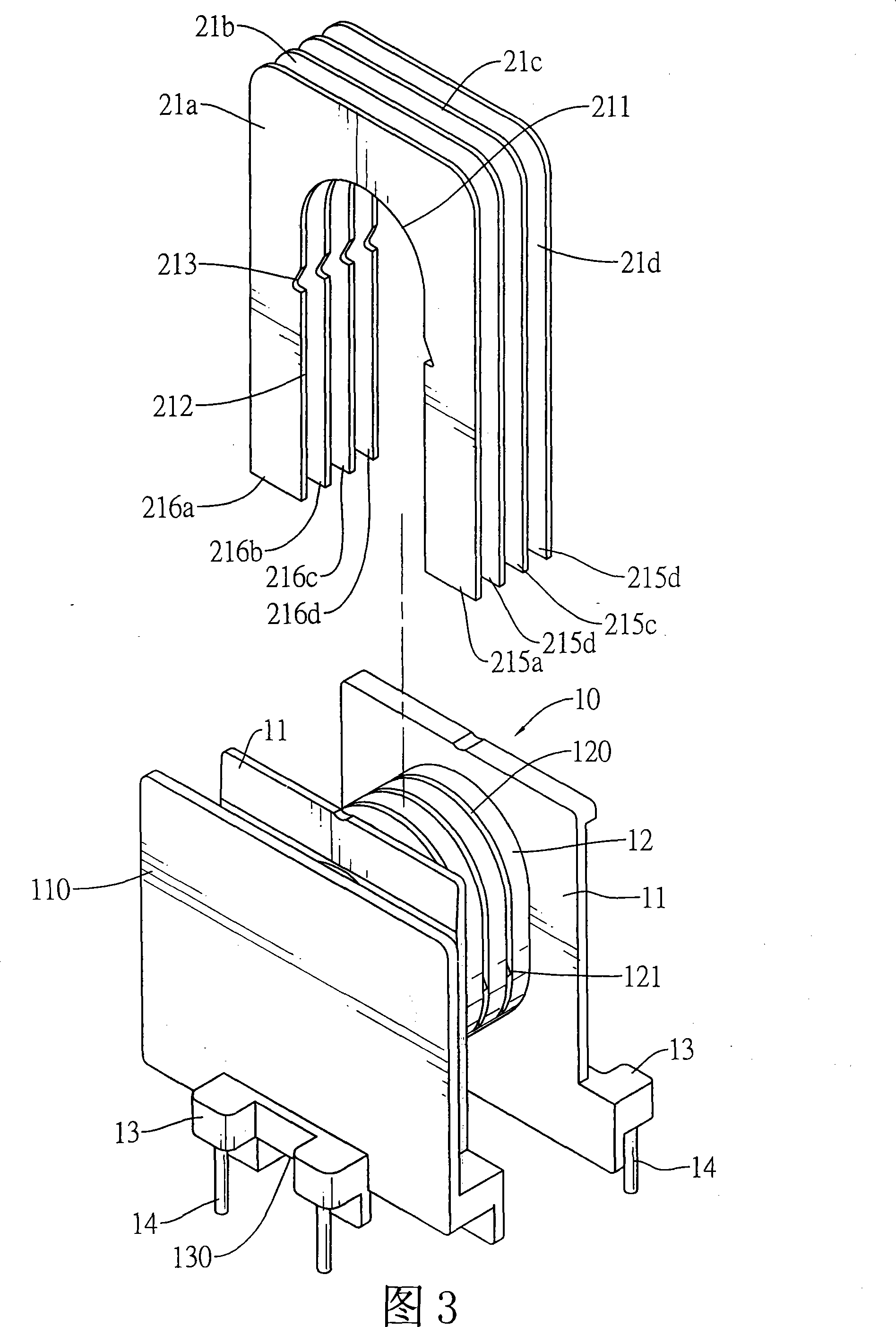

[0053]Regarding a preferred embodiment of the present invention, please refer to Fig. 1 and shown in Fig. 2 at first, mainly be to be provided with a copper sheet winding 20, a coil winding 30 and an iron core 40 on a horizontal wire stand 10; The sheet winding 20 can be used as the primary side or the secondary side, which means that when the copper sheet winding 20 is used as the primary side winding, the coil winding 30 is used as the secondary side winding; otherwise, the copper sheet winding 20 is used as the secondary side winding, and the coil winding 30 That is, the primary side winding; in addition, the present invention can be implemented in step-down transformers and step-up transformers respectively.

[0054] Please also refer to FIG. 3 , the wire frame 10 mainly forms a hollow winding part 12 in the horizontal direction between two opposite vertical side parts 11, and the bottom ends of the two vertical side parts 11 are respectively formed with pin seats 13 , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com