Tilt-rotor plane operated and propelled by thrust scull and slipstream rudder

A technology of tilt rotor and slipstream rudder, which is applied in rotorcraft, aircraft parts, aircraft control, etc. It can solve the problem that the aeroelastic characteristics are difficult to meet the design requirements, the propulsion efficiency is not very high, and the lift and drag characteristics of forward flight are not very good, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

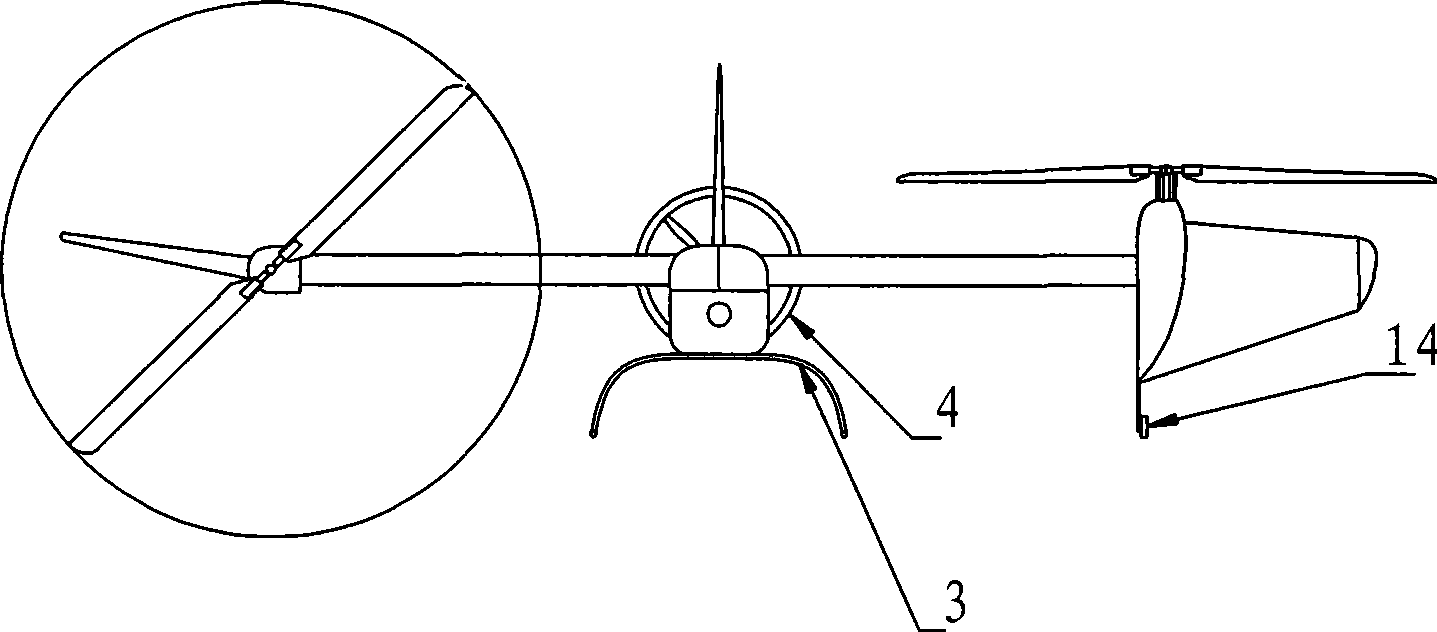

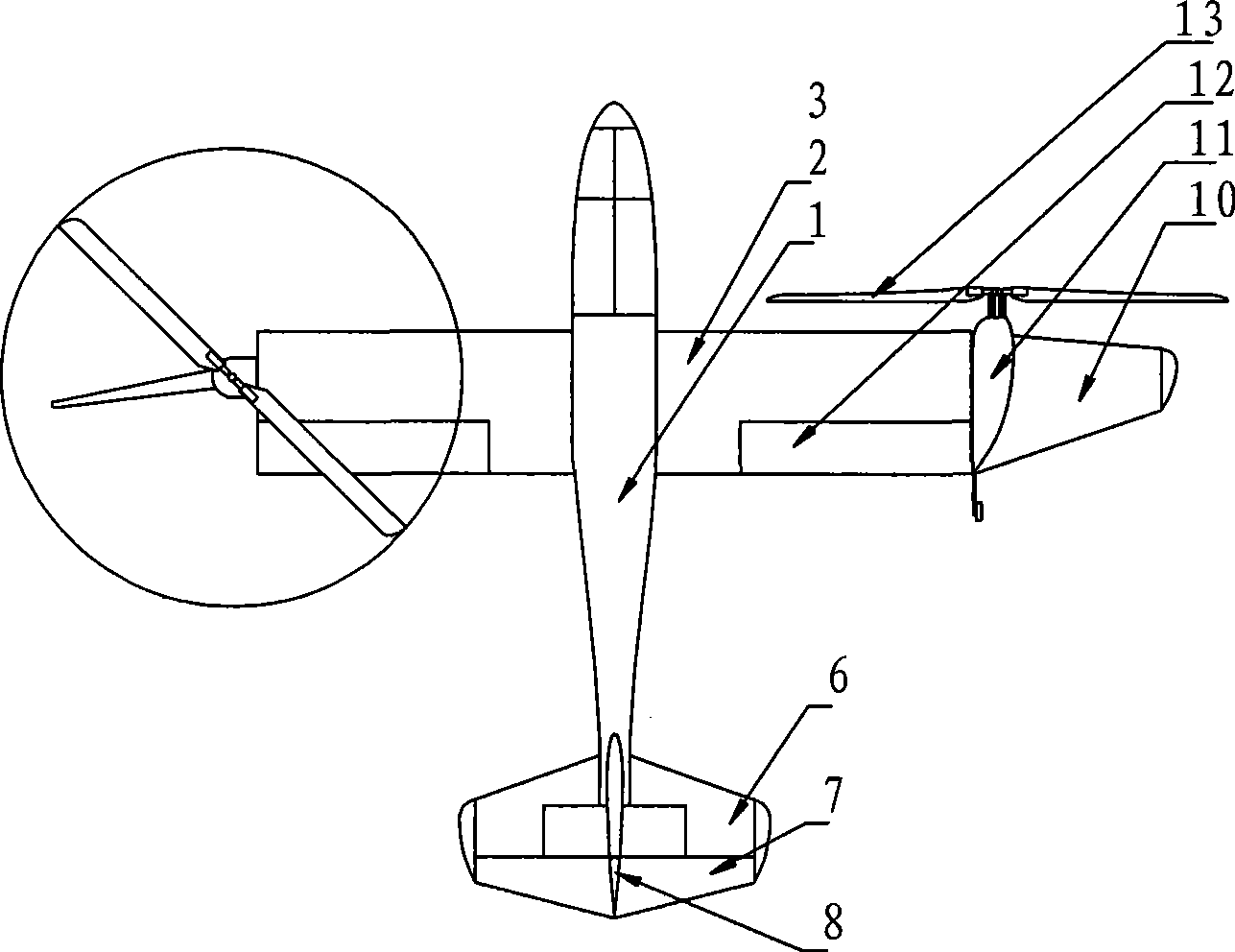

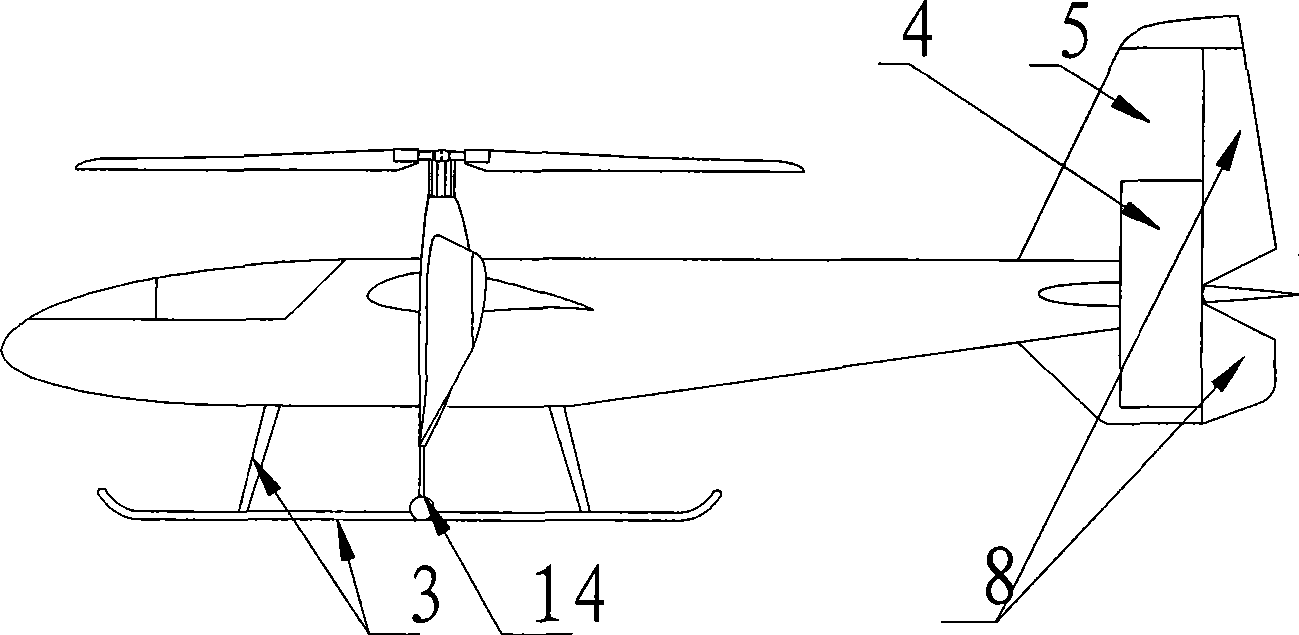

[0043] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , shown in Figure 9, its specific implementation is as follows:

[0044] The invention is a tilt rotor aircraft controlled and propelled by a thrust tail rotor and a slipstream rudder, and adopts a design of parallel double rotors and a conventional aerodynamic layout. It is composed of fuselage 1, wing 2, empennage, thrust tail rotor and slipstream rudder system, landing gear, power and fuel system, transmission system, rotor system, rotor nacelle, and rotor nacelle tilting system. The wing 2 is installed on both sides of the middle section of the fuselage 1, the empennage is installed on the tail of the fuselage 1, the thrust tail rotor and the slipstream rudder system are installed on the empennage, the main body of the landing gear is located on the belly of the fuselage 1, and the power and fuel systems are installed on the fuselage 1. The inside of the middle se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com