Purification method of solid cyanamide

A purification method, a technology of cyanamide, applied in the field of purification of solid cyanamide, can solve the problems of cyanamide production enterprises such as storage and transportation difficulties, occurrence of combustion or explosion, easy polymerization or decomposition, etc. , Low production cost, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Take 60g of methanol (purity 99.5%) into a 500mL three-necked flask equipped with a stirrer and thermometer, while stirring, add 300g of solid cyanamide (purity 93.0%) produced by cooling and crystallization of liquid cyanamide. Heat the water bath to 25°C to fully dissolve the solid cyanamide, and then filter to filter out the impurities in the cyanamide. The resulting filtrate is collected in a 500mL three-necked flask equipped with a stirrer and a thermometer, and the three-necked flask is put into frozen brine Cool and crystallize while turning on the stirrer. When the temperature drops below -5°C, continue to stir for 20 minutes, filter the precipitated crystals, and recycle the mother liquor. The filtered crystals were dried in vacuum to obtain a white stable solid cyanamide.

Embodiment 2

[0011] Take 110g of methanol (purity 99.5%) into a 500mL three-necked flask equipped with a stirrer and thermometer, while stirring, add 200g of solid cyanamide (purity 93.0%) produced by cooling and crystallization of liquid cyanamide. The water bath was heated to 40°C to fully dissolve the solid cyanamide, and then filtered. The resulting filtrate was collected in a 500mL three-necked flask equipped with a stirrer and a thermometer. The three-necked flask was placed in frozen brine to cool and crystallize, and the stirrer was turned on. When the temperature drops below 5°C, the precipitated crystals are filtered and the mother liquor is recycled. The filtered crystals were dried in vacuum to obtain a white stable solid cyanamide.

Embodiment 3

[0013] Take 150g of methanol (purity 99.5%) into a 500mL three-necked flask equipped with a stirrer and thermometer, while stirring, add 100g of solid cyanamide (purity 93.0%) produced by cooling and crystallization of liquid cyanamide, The water bath was heated to 30°C to fully dissolve the solid cyanamide, and then filtered. The resulting filtrate was collected in a 500 mL three-necked flask equipped with a stirrer and a thermometer. The three-necked flask was placed in frozen brine to cool and crystallize, and the stirrer was turned on. When the temperature drops below 0°C, the precipitated crystals are filtered and the mother liquor is recycled. The filtered crystals were dried in vacuum to obtain a white stable solid cyanamide.

[0014] In the above three embodiments, under other conditions unchanged, methanol will be replaced with ethanol, ether, and acetone respectively, and high-purity cyanamide can also be obtained.

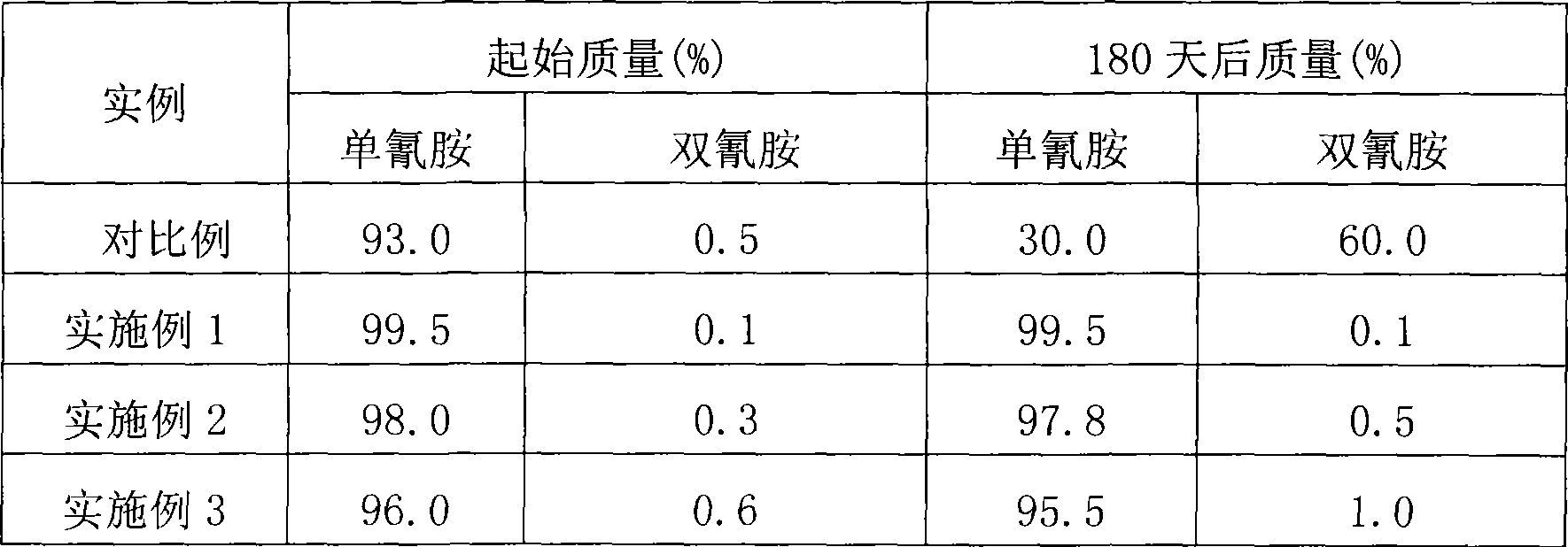

[0015] The stability of solid cyanamide purified by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com