Lubricant for drilling fluids and preparation method thereof

A technology for lubricants and drilling fluids, applied in the field of lubricants and their preparation, can solve the problems of easy precipitation of oil phase and difficult dispersion of oil treatment agents, etc., and achieve low adhesion coefficient, low requirements for equipment and environmental conditions, and control The effect of the coefficient of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The lubricant components are as follows:

[0024] All are parts by weight (unit: kilogram), and the total amount is 100 parts:

[0025] 99.2 parts of liquid paraffin, 0.8 parts of nonionic surfactant Span80.

[0026] Preparation:

[0027] Mix 99.2 parts of liquid paraffin and 0.8 parts of nonionic surfactant Span80 uniformly in a reactor, and keep stirring at 25°C and 300 rpm for 30 minutes to obtain a lubricant for drilling fluid.

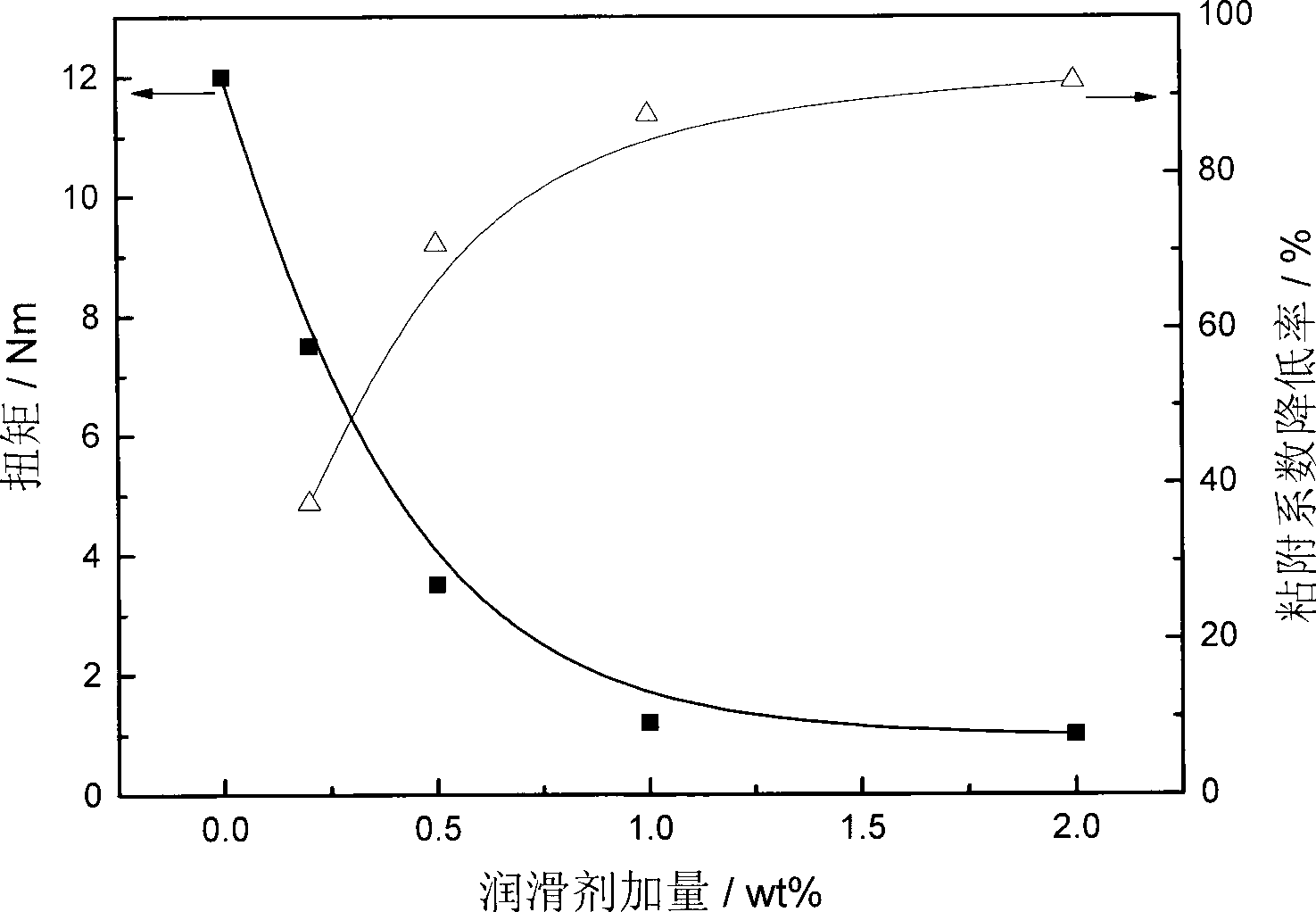

[0028] Take the lubricant prepared by the above method, and investigate the reduction rate of its adhesion coefficient, and the results are shown in the table.

[0029] Lubricant Appearance Uniform and transparent Reduction rate of adhesion coefficient (0.5wt% addition) 70-80% Filtration / mL 13-15

[0030] The adhesion coefficient measurement experiment of the lubricant that the present invention relates to is as follows:

[0031] Preparation of base slurry: Add 16g of calcareous bentonite and 0.8g of anhydrou...

Embodiment 2

[0039] Method is substantially as described in Example 1, the difference is:

[0040] The components are as follows, all in parts by weight (unit: kilogram), and the total amount is 100 parts:

[0041] 99.5 parts of 7# white oil, 0.5 parts of Brij52.

[0042] The above components were uniformly mixed in the reactor, and stirred continuously for 60 minutes under the conditions of 30° C. and 100 rpm to obtain a lubricant for drilling fluid.

[0043] Take the lubricant prepared by the above method, and investigate the reduction rate of its adhesion coefficient. The relevant experimental data are as follows:

[0044] Lubricant Appearance Uniform and transparent Adhesion coefficient reduction rate (0.2wt% addition) 30-40% Filtration / mL 13-15

Embodiment 3

[0046] Method is substantially as described in embodiment 1 or 2, the difference is:

[0047] The components are as follows, all in parts by weight (unit: kilogram), and the total amount is 100 parts:

[0048] 99 parts of 10# white oil, 1 part of Span80.

[0049] The above components were uniformly mixed in the reactor, and stirred continuously for 15 minutes under the conditions of 20° C. and 3000 rpm to obtain a lubricant for drilling fluid.

[0050] Take the lubricant prepared by the above method, and investigate the reduction rate of its adhesion coefficient. The relevant experimental data are as follows:

[0051] Lubricant Appearance Uniform and transparent Adhesion coefficient reduction rate (1wt% addition) 80-95% Filtration / mL 13-14

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com