Drying regeneration process by employing one barrel type dehumidifying drier

A dryer and drum type technology, which is applied in the direction of dryer, drying gas arrangement, drying, etc., can solve the problems of high price, complicated manufacturing process and large space occupation of rotary honeycomb dehumidification source, etc. Small space, low noise, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

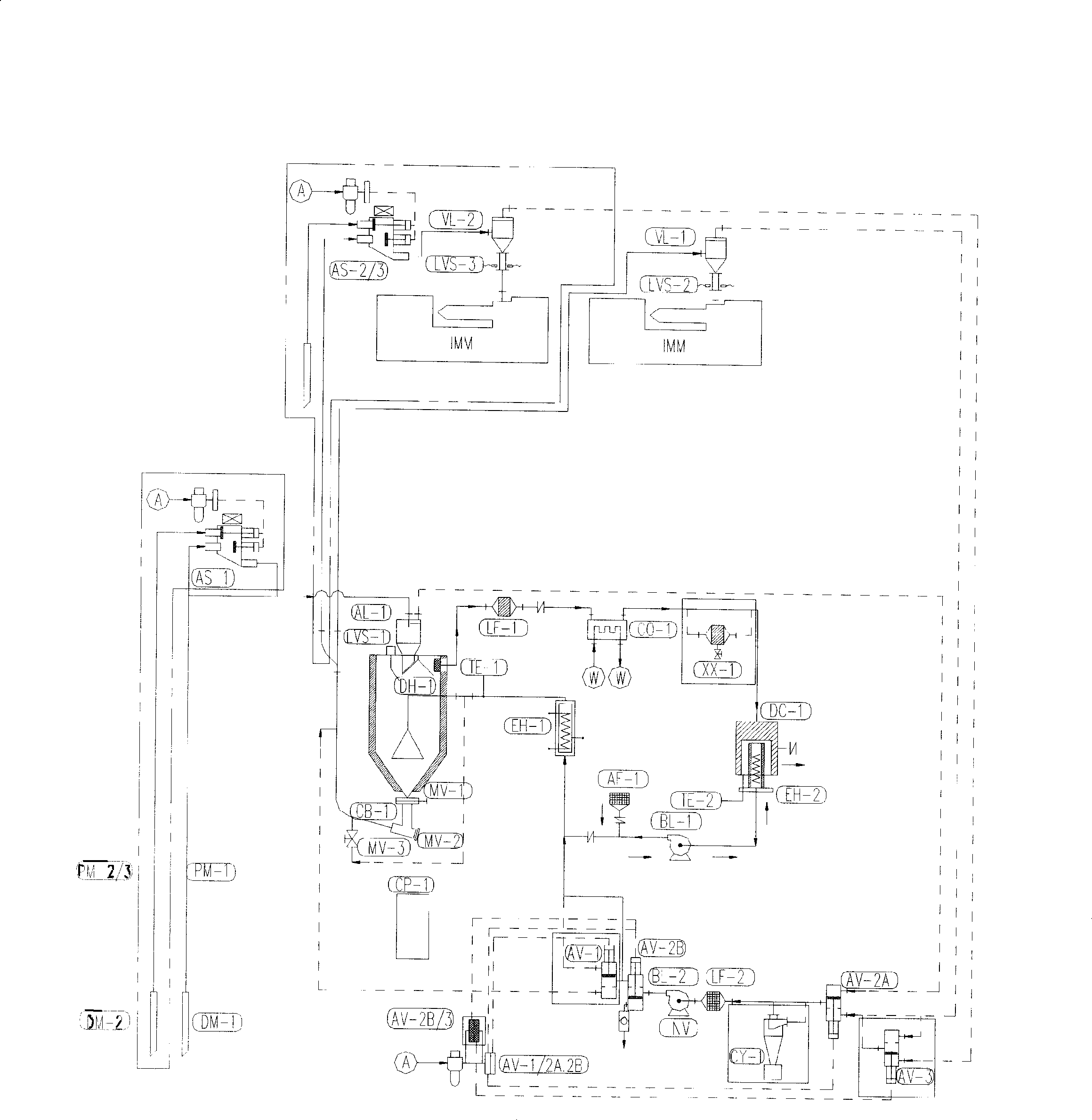

[0015] Such as figure 1 As shown, the drying and regeneration process of a drum dehumidification dryer is used, which includes a drying circulating air system and a regeneration circulating system.

[0016] The flow of the dry circulating air system is: drying cylinder DH-1→filter LF-1→cooler CO-1→one cylinder dehumidification source DC-1→drying regeneration fan BL-1→drying heating pipe EH -1→drying cylinder DH-1;

[0017] The flow of the regeneration cycle system is: filter AF-1→dry regeneration fan BL-1→regeneration heating tube EH-2→one-drum dehumidification source DC-1→empty;

[0018] The material to be processed is sucked by the conveying suction pipes DM-1 and DM-2, and conveyed to the automatic simple mixing device AS-1 through the PVC hose PM-1 and PM-2 / 3. After mixing, it enters the primary conveying hopper AL-1. Then it is discharged after being dried and regenerated by the above-mentioned drying circulating air system and regenerative circulating system. The dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com