High-temperature material handling spiral

A technology for conveying spirals and high-temperature materials, which is applied in the field of circular rotary hearth furnace discharge spirals and high-temperature material conveying spirals. It can solve the problems of increasing the difficulty of blade manufacturing, low propulsion efficiency, and short service life, and achieves good water cooling effects and improved Abrasive wear resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

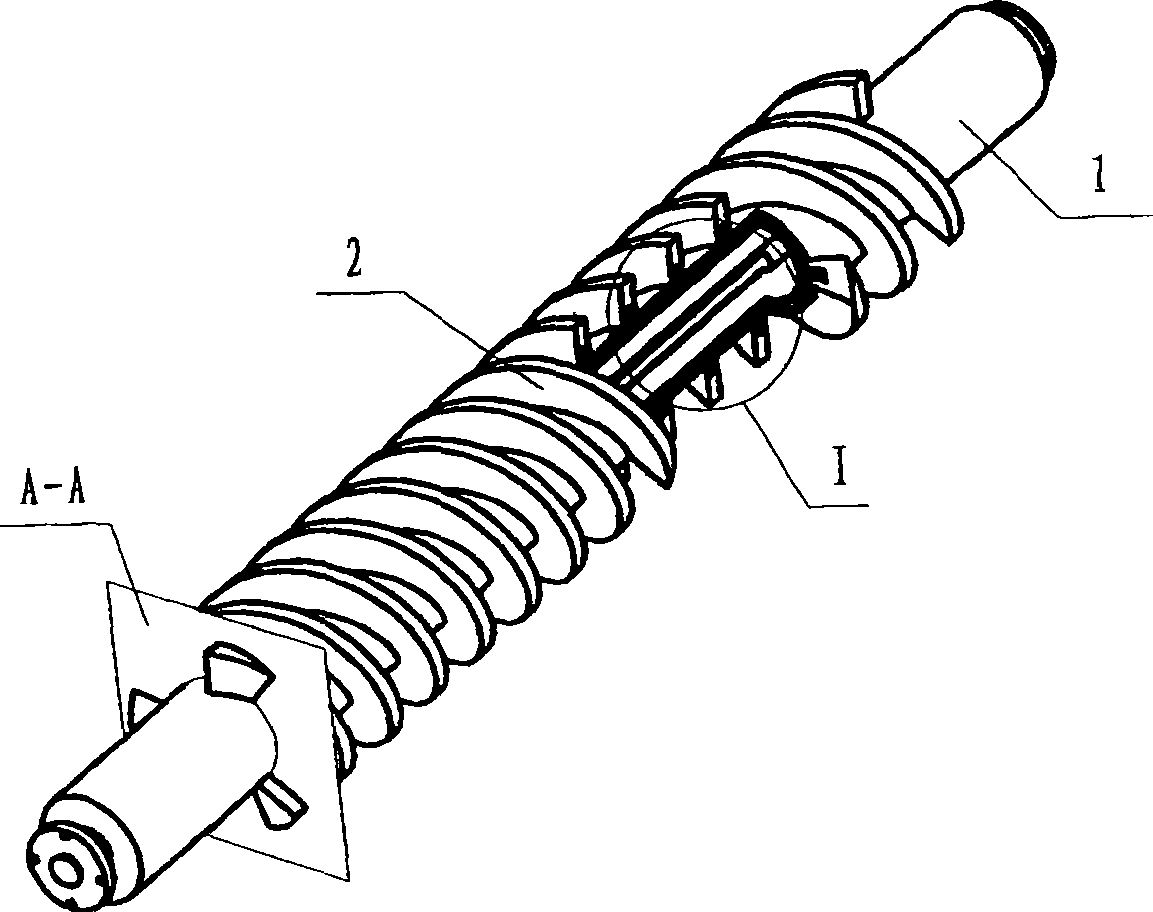

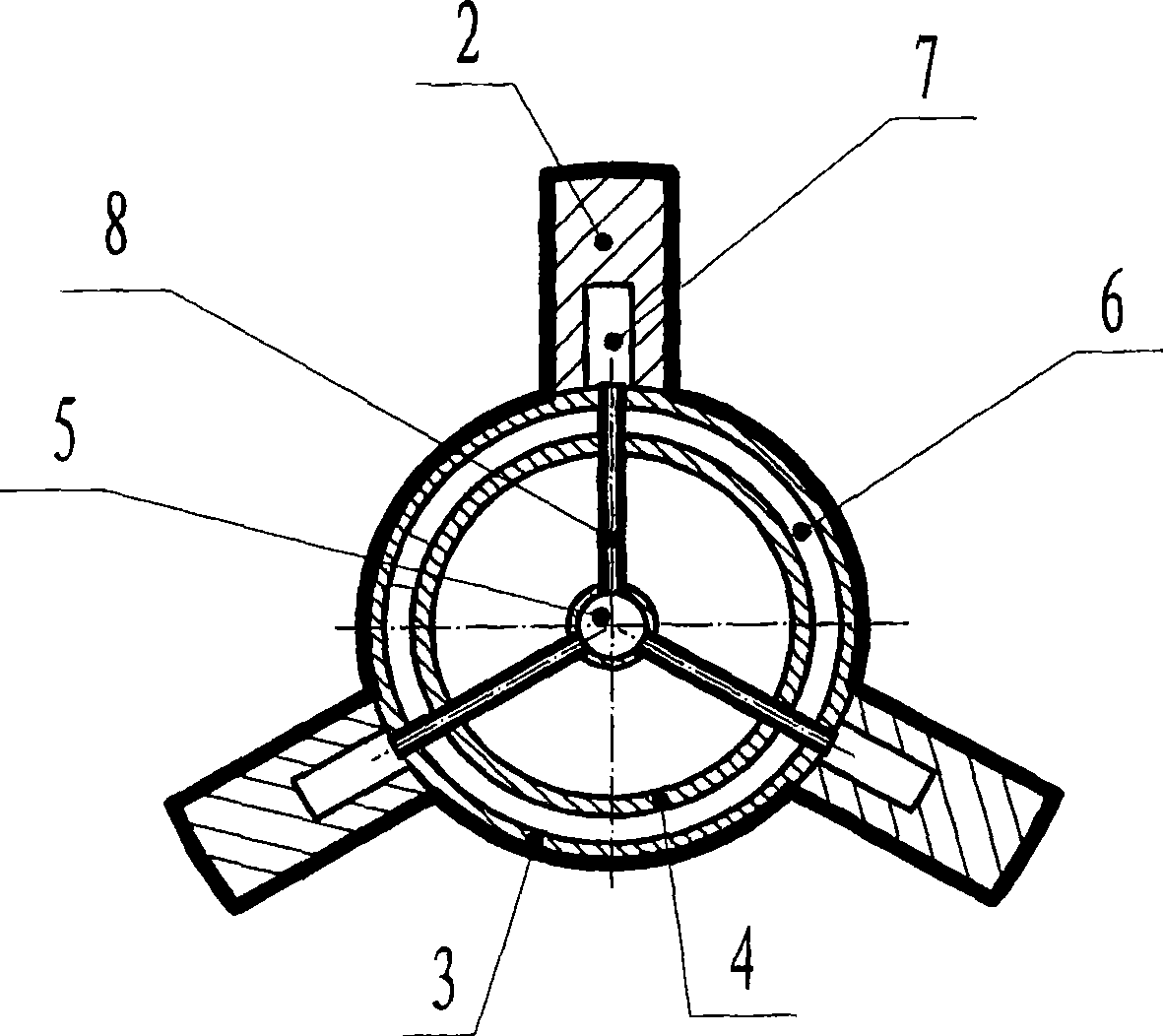

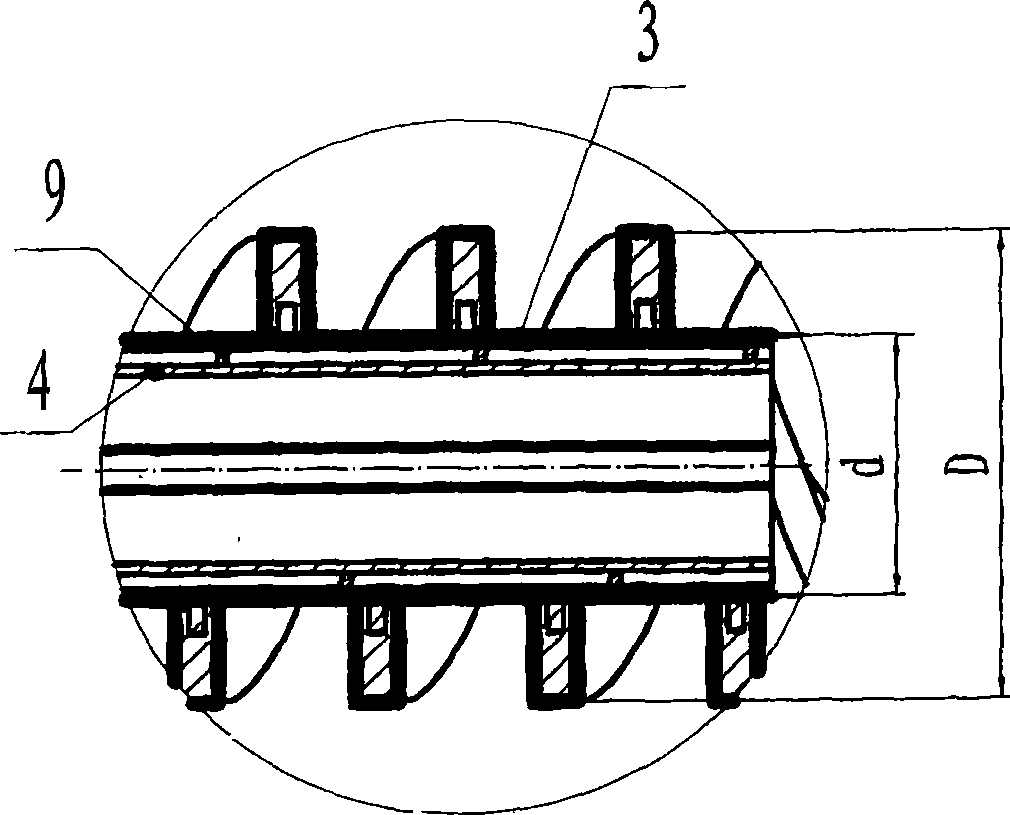

[0016] from figure 1 , figure 2 , image 3 It can be seen from the figure that the present invention is a high-temperature material conveying screw, which includes a main shaft 1 and several conveying screw blades 2 welded and fixed on the outside of the main shaft. The screw blades 2 and the main shaft 1 are integrally structured. The main shaft 1 of the present invention is a hollow shaft with double sleeves, and the outer sleeve 3 of the main shaft and the helical blade 2 are integrally made by surfacing welding technology. The present invention uses a high-temperature abrasive wear-resistant surfacing welding alloy material to carry out surfacing welding on the surface of the spiral blade 2 and the main shaft 1 to resist wear from high-temperature metallized pellets. The anti-high temperature abrasive wear surfacing alloy material used in the present invention is the surfacing alloy material disclosed in Chinese patent 011352310, which is mainly a high-carbon and high-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com