Compensation process for detecting temperature for temperature sensor

A temperature sensor and compensation method technology, applied in thermometer testing/calibration, thermometers, thermometers using electric/magnetic elements that are directly sensitive to heat, etc., can solve the problem of inability to realize automation, informatization, low efficiency, and inability to realize process control And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

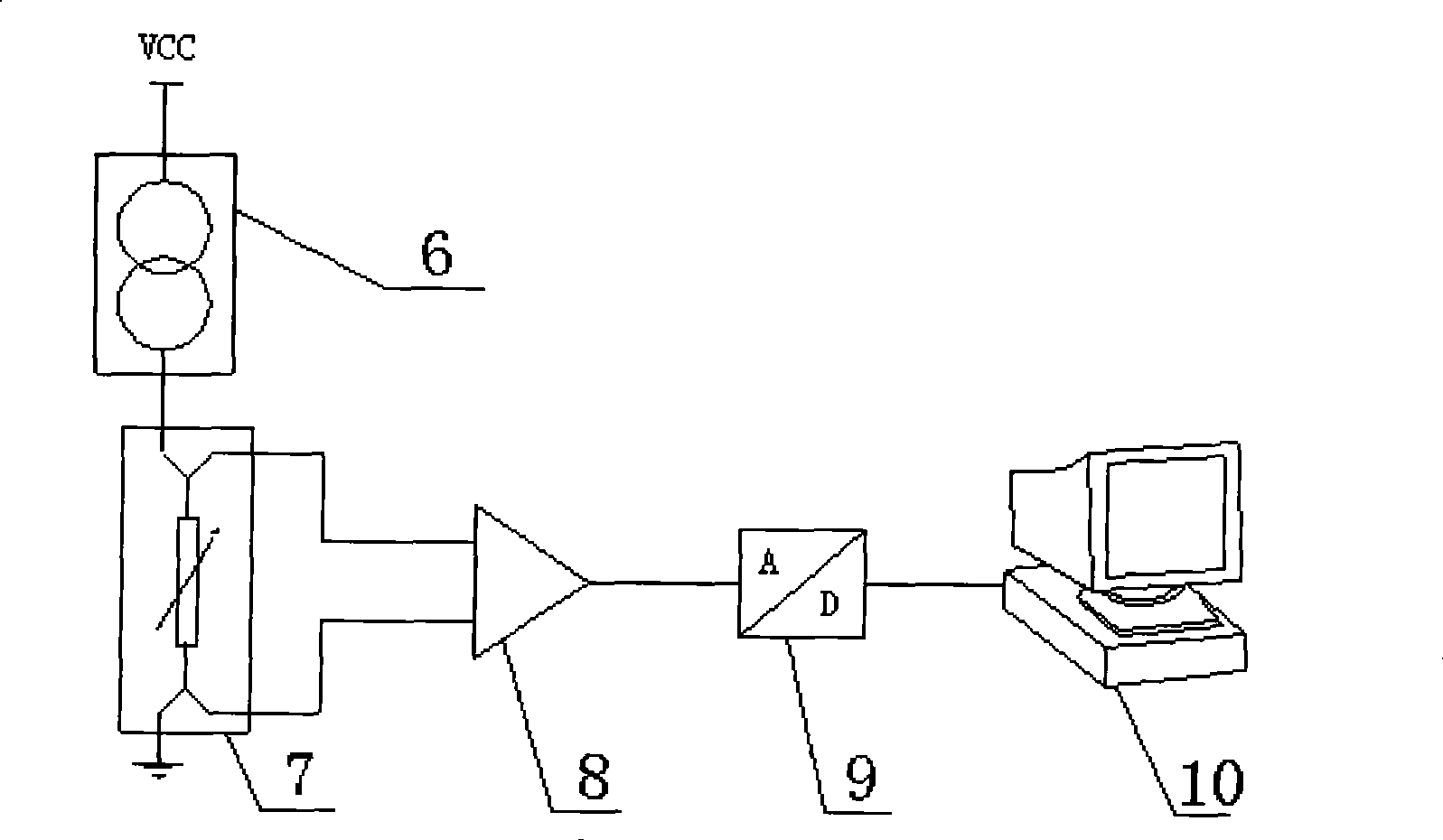

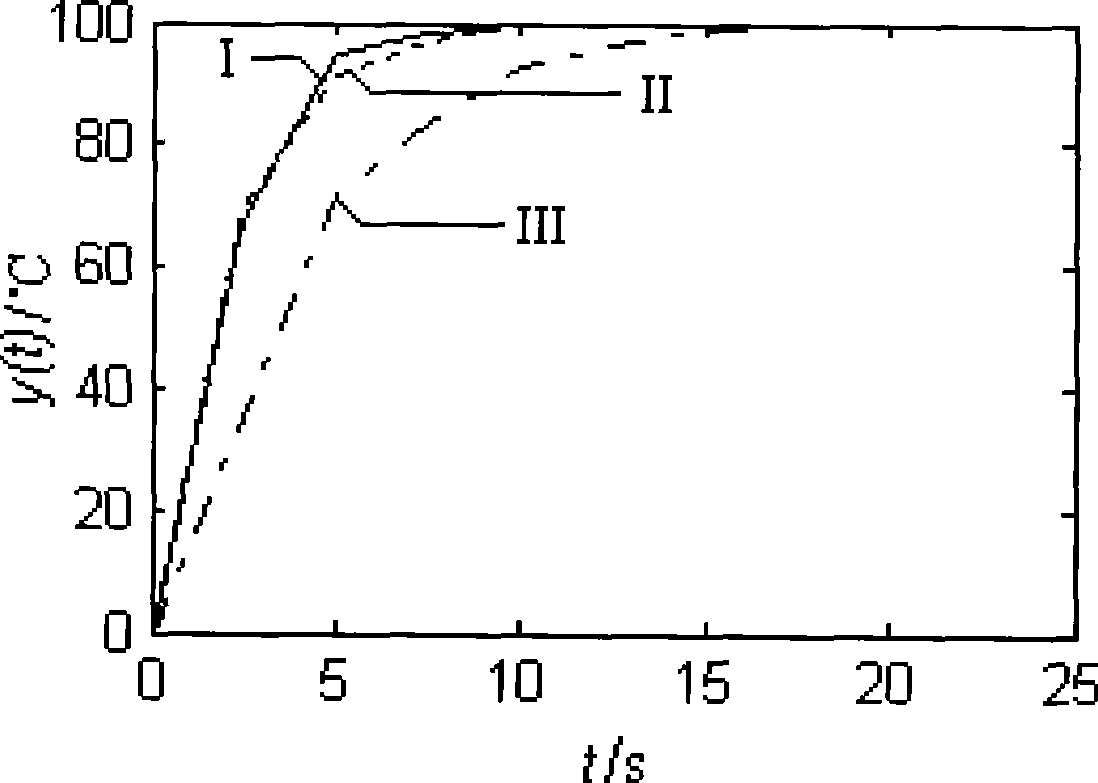

[0036] The specific embodiment of the present invention is described in detail in conjunction with the accompanying drawings and technical solutions. The present invention selects a temperature sensor Pt100 with a stainless steel sheath diameter of Φ4mm and a length of 75mm.

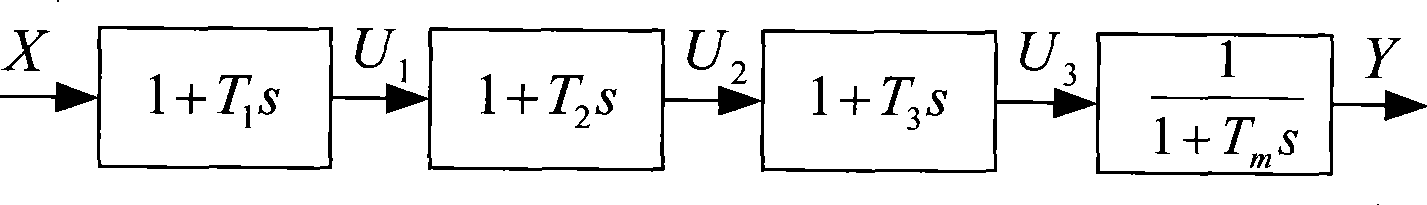

[0037] 1. Establish the mathematical model of the temperature sensor Pt100 and the national standard No. 1 mercury thermometer, and determine the transfer function:

[0038] 1) Judging from the structure of the temperature sensor Pt100, the heat is transferred to the platinum thermal resistance wire through the sheath and the heat conduction medium. In the detection of the tested object, the heating environment is often a constant rate of heating, constant rate of cooling or constant temperature environment, and the influence of pure hysteresis is not significant. Each heat transfer can be regarded as a first-order inertial system with pure hysteresis, then the temperature sensor Pt100 can be regarded as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com