Method of providing consistent quality of target material removal by lasers having different output performance characteristics

一种激光器、质量的技术,应用在激光器、激光器零部件、声子激发器等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention require the use of solid-state UV lasers to perform drilling and ablation of circuit materials such as uniform films with or without metal cladding, particle-filled resins, polyimides, and fiber-reinforced polymers. The Model ABF circuit board dielectric material manufactured by Ajinomoto Fine-Techno Co., Inc. of Kawasaki, Japan is the target material, and the following description is based on this target material. The following description is directed to drilling, but the invention is also applicable to other methods of material removal, such as joint severing, material trimming, annealing, and scribing.

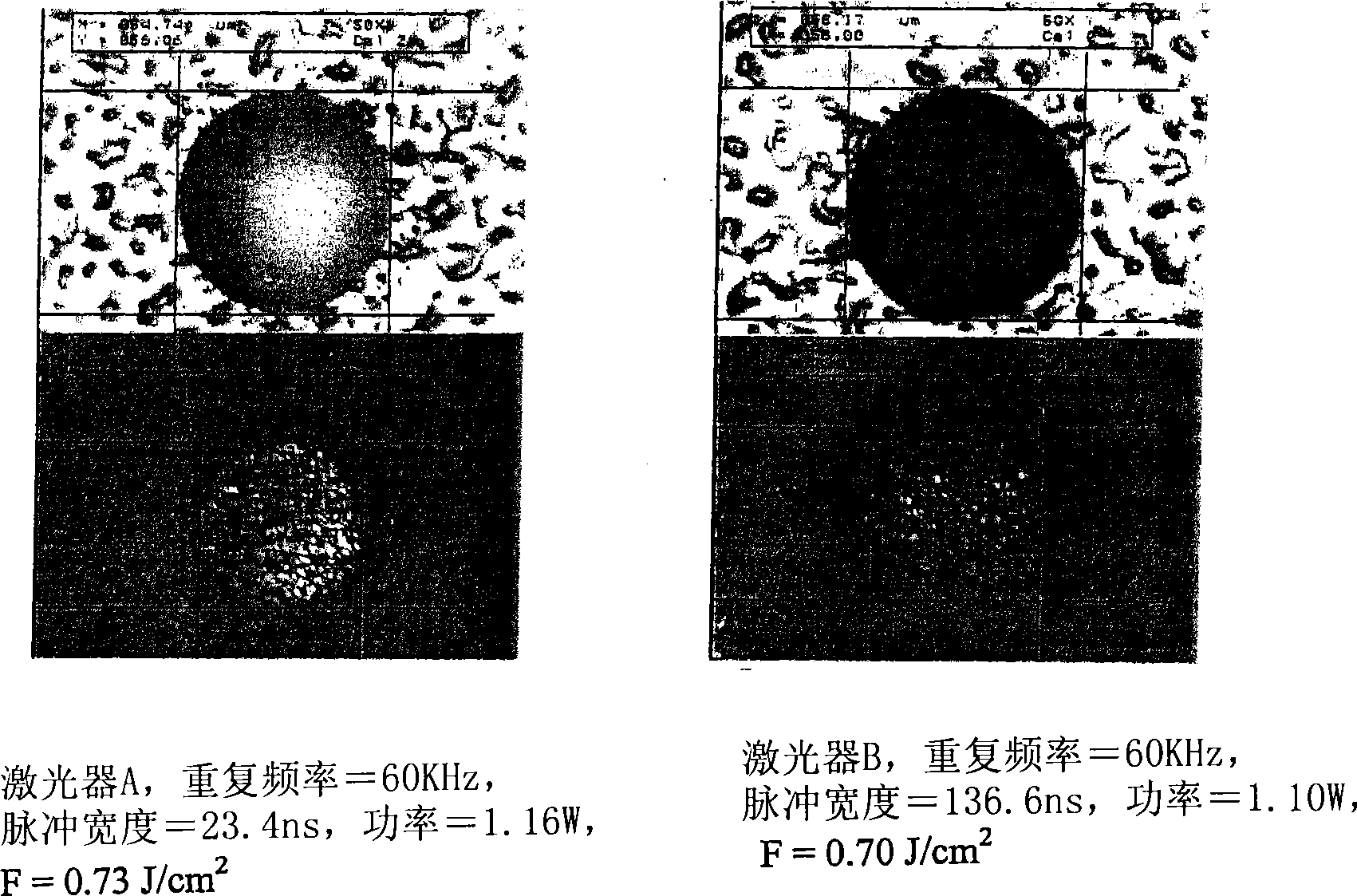

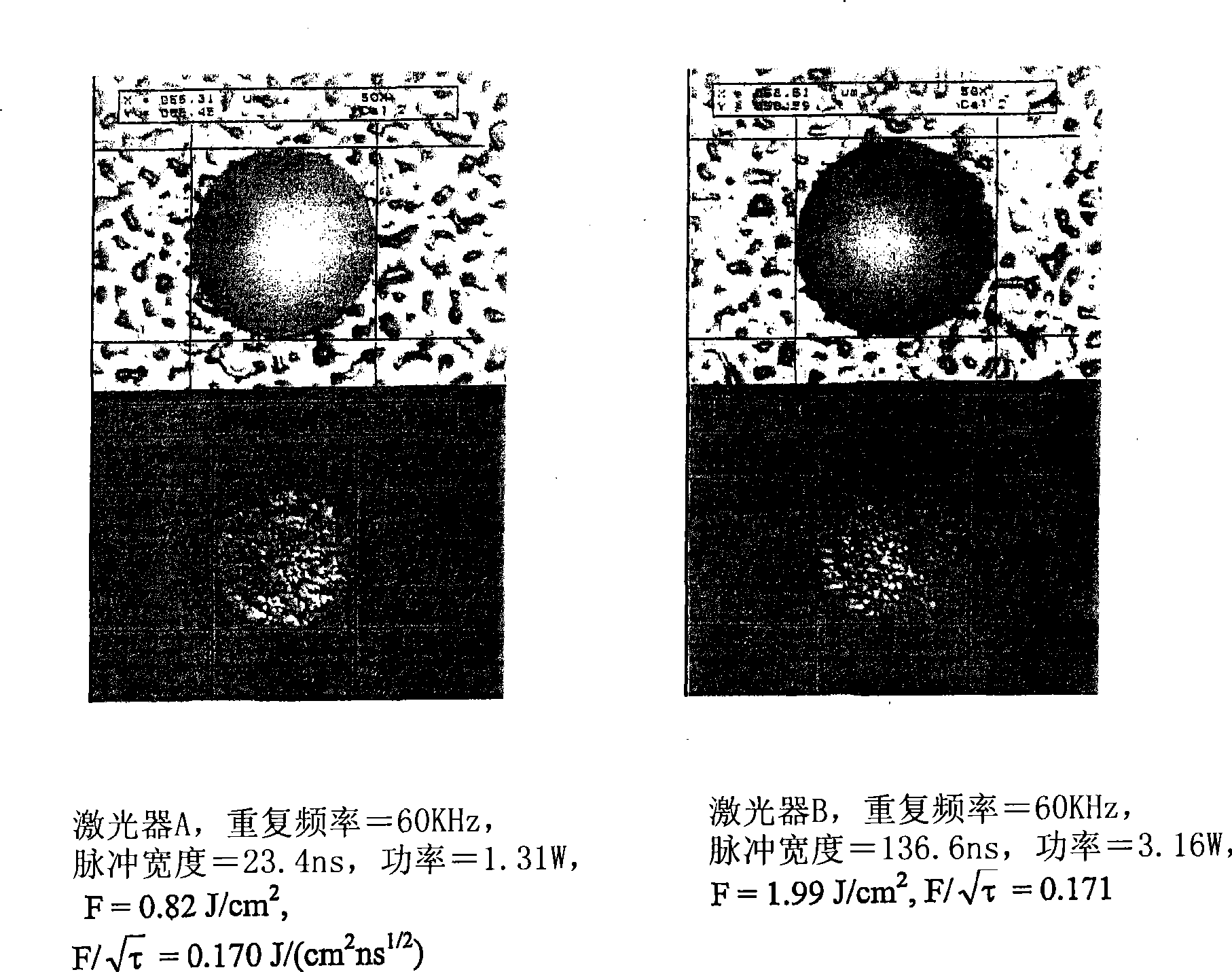

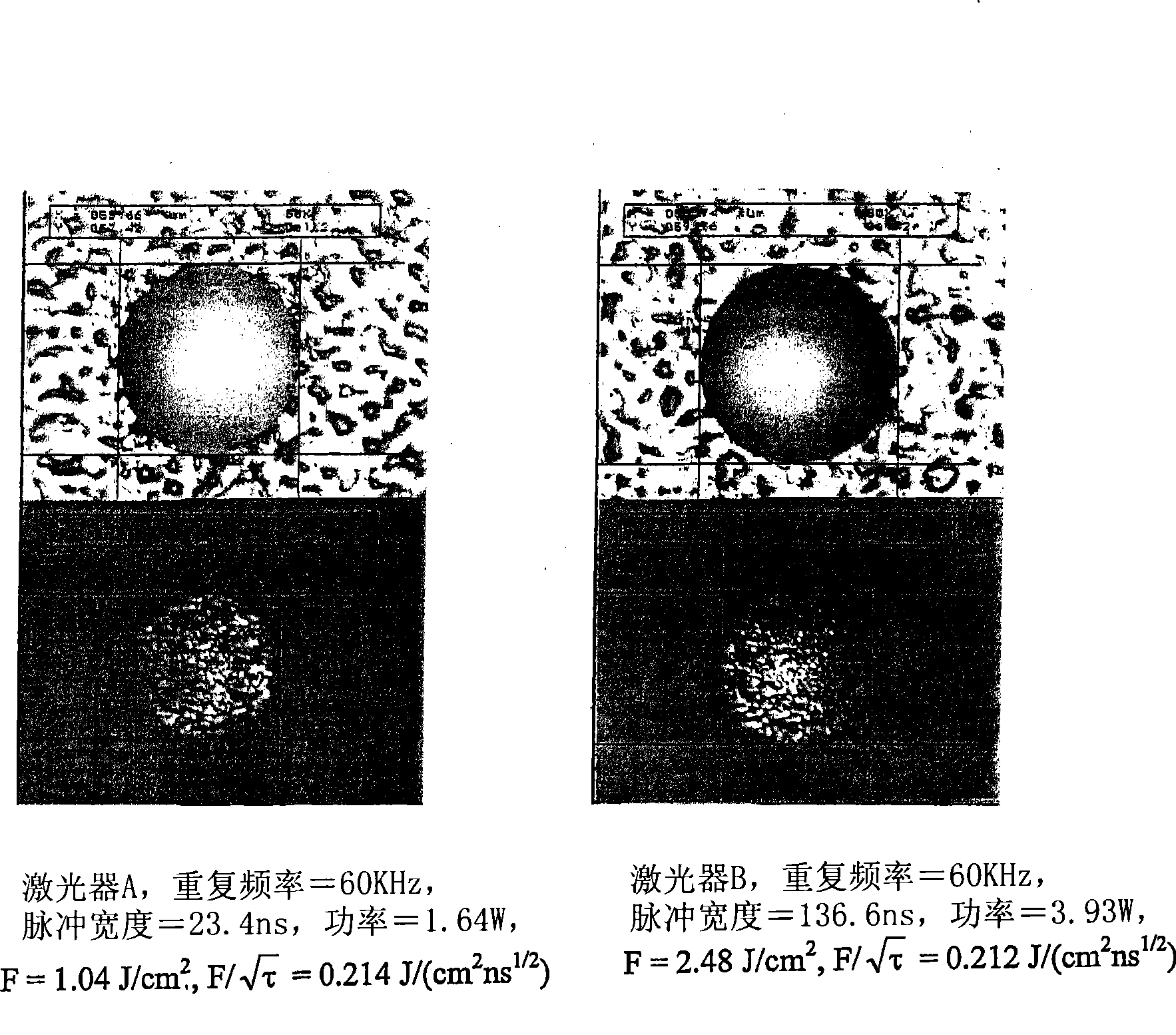

[0015] figure 1 is a set of four photomicrographs showing the problem solved by the present invention. figure 1 Light micrographs are shown of two 58 micron diameter drilled holes drilled to a depth of 35 microns to 40 microns with approximately the same fluence level using a 355 nm UV laser with different pulse widths....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com