Mobile riding wheel frame

A movable type and turbine technology, which is applied in the manufacture of converters, etc., can solve the problems of loose support rollers and cannot solve the problems of maintenance and replacement in high temperature environments, and achieve the effects of avoiding replacement, shortening the replacement and maintenance cycle, and improving safety and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

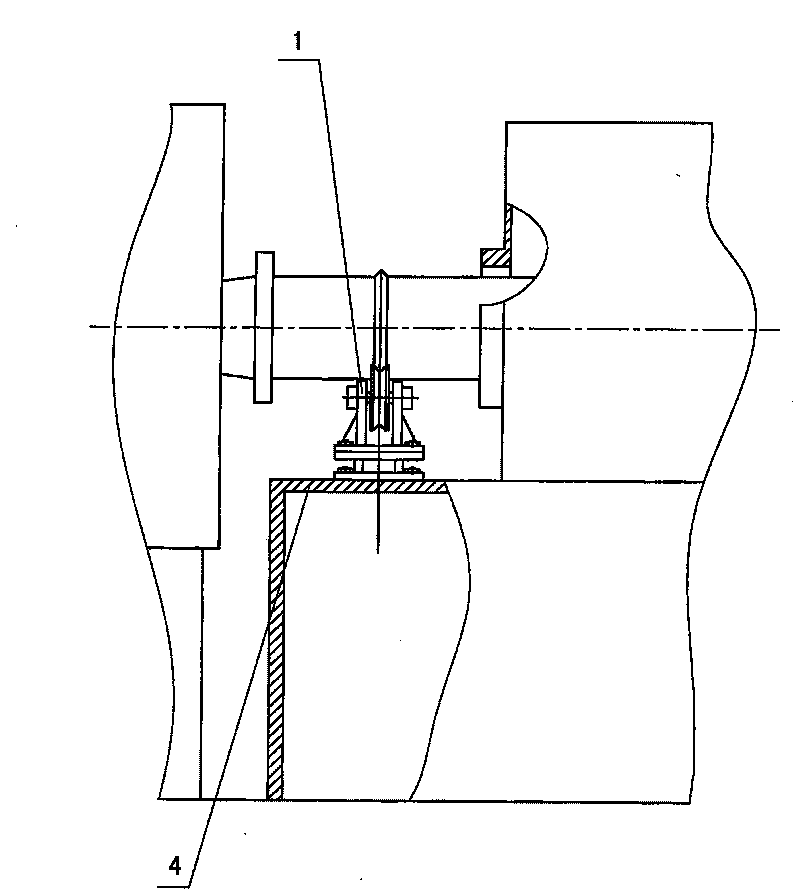

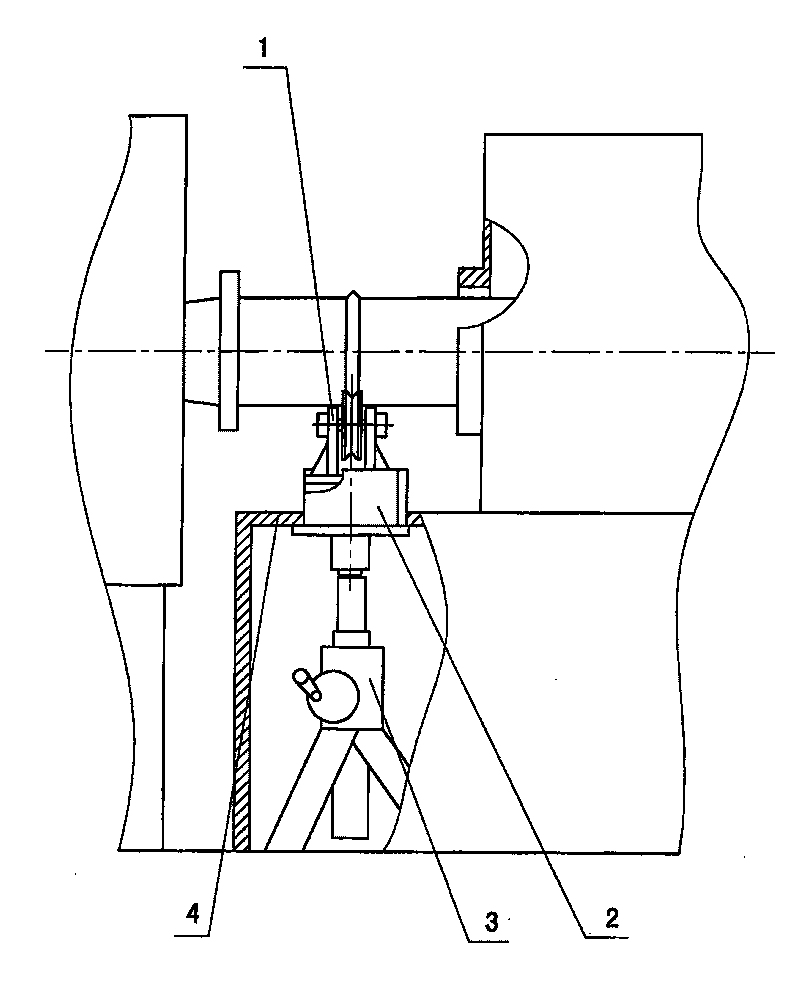

[0045] A rectangular lifting hole is set on the table top 4 of the steel plate stand, and a jack lifting support mechanism 3 is set below the lifting hole inside the steel plate stand, and the jack supports the movable connecting frame 2, and the movable connecting frame 2 buckles Supporting wheel 1.

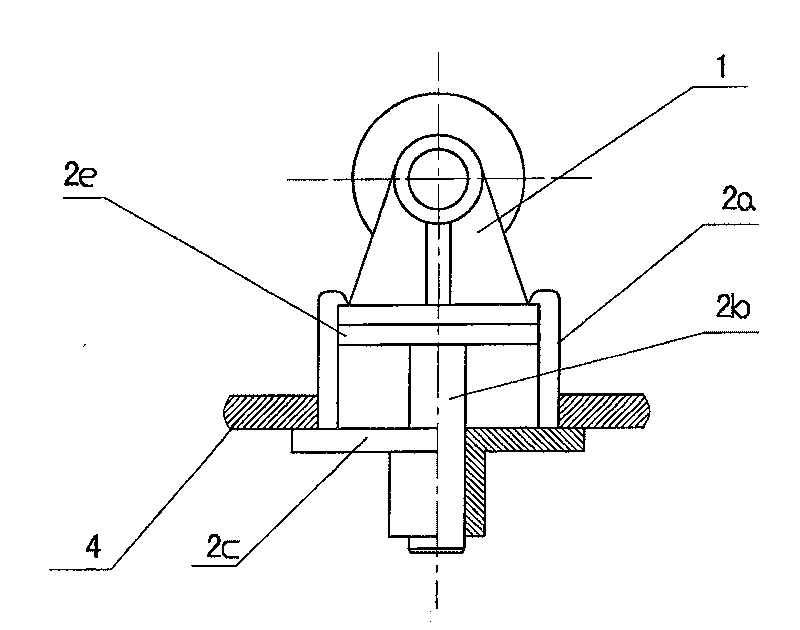

[0046] The movable connection frame 2 includes a supporting plate 2c, a push rod 2b, a top plate 2e and a limiting plate 2a;

[0047] The size of the supporting plate 2c is larger than the opening of the lifting hole, and a sliding hole is provided in the center of the supporting plate 2c, and the sliding hole is a circular tube with a length;

[0048] Two limit plates 2a are vertically fixed on both sides of the supporting plate 2c, the distance between the two limit plates 2a is equal to the width of the base of the supporting wheel 1, and there is a gap that can move mutually; the upper end of the limit plate 2a is The size of the rectangle formed on the outside of the two l...

Embodiment 2

[0054] Same as Embodiment 1, only wherein the lifting support mechanism 3 is a lever mechanism, that is, one end of the lever is against the lower edge of the push rod 2b of the movable connection frame 2, the fulcrum of the lever is erected on the ground, and the other end of the lever is pressed down. Lock in the form of a buckle, firmly press one end of the lever against the lower edge of the top rod 2b of the movable connection frame 2, lift the supporting wheel 1, and firmly press and lock the base of the supporting wheel 1 between the top plate 2e and the stop , The supporting roller 1 also supports the high-temperature heating furnace tube, and the operation of this mechanism is simple and easy. In order to ensure positional accuracy, a fine-tuning screw can be provided on the hasp.

Embodiment 3

[0056] Such as Figure 5 , 6 As shown, on the basis of Embodiment 1, a flange is protruded from the upper surface of the top plate 2e to form a flange top plate 2e-2, and a sleeve-type step sleeve 2f is set between the two limiting plates 2a, and the flange The peripheral diameter of the top plate 2e-2 is smaller than the inner diameter of the step sleeve 2f, and a flange hole with the same flange position as the flange top plate 2e-2 and a corresponding diameter is opened at the bottom of the supporting wheel 1 base. When the lifting support mechanism 3 rises, it pushes the push rod 2b to move upwards, and the flange top plate 2e-2 pushes the base of the supporting roller 1 to rise to achieve the purpose of support. Simultaneously, because the flange on the upper surface of the flange top plate 2e-2 is embedded in the flange hole of the base of the supporting wheel 1, the base of the supporting wheel 1 is limited by the flange on the upper surface of the flange top plate 2e-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com