Supporting body for speed reduction clutch of pulsator washing machine

A deceleration clutch and washing machine technology, applied in the field of washing machines, can solve the problems of complex non-ferrous metal die-casting process, high cost of environmental protection electroplating process, serious environmental pollution, etc., and achieve the effects of shortening the production cycle, light weight, and simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

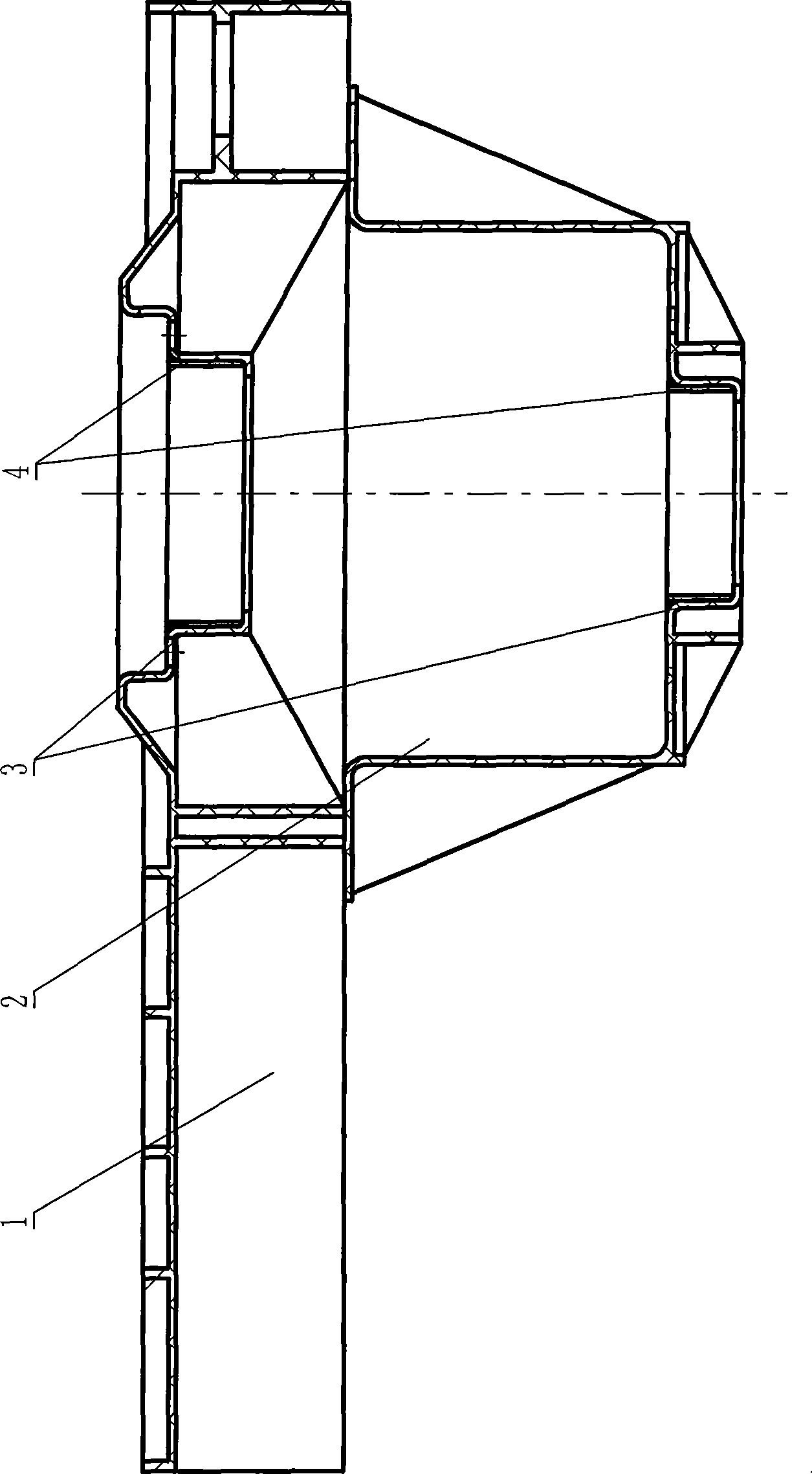

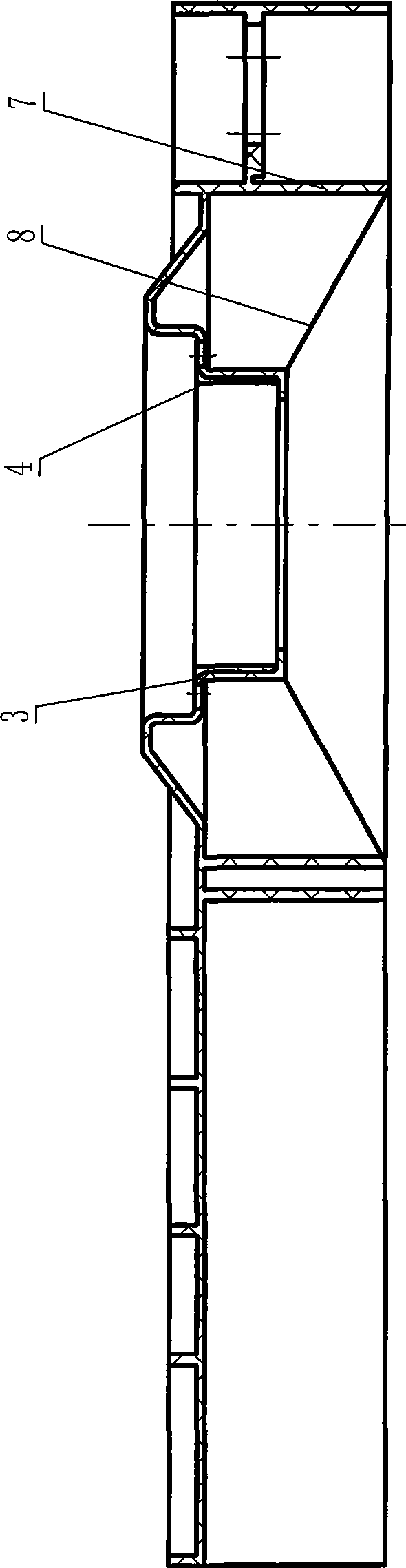

[0029] combine figure 1 , a pulsator type washing machine deceleration clutch support body, which is mainly composed of a support plate 1 and a support bracket 2 integrally injection-molded from reinforced polypropylene, and an inner cavity is formed between the support plate 1 and the support bracket 2 for installation The deceleration clutch is connected with the outer tub of the washing machine through the support plate 1. The support plate 1 and the support bracket 2 are provided with a special bearing seat 3, and the special bearing seat 3 has a built-in universal elastic positioning ring 4 made of metal material.

[0030] combine Figure 2-6 , is a schematic diagram of the shape and structure of the support plate 1; combined with Figure 7-9, it is a schematic diagram of the shape and structure of the support bracket 2; a universal metal elastic positioning ring 4 is provided in the special bearing seat 3 of the support plate 1 and the support bracket 2, It can automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com