Non-contact type capacitance induction level sensor

A liquid level sensor and capacitive sensing technology, applied in the field of liquid level sensors, can solve problems such as short service life, failure of water level detection, and easy to be damaged by lightning strikes, so as to reduce the probability of failure and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

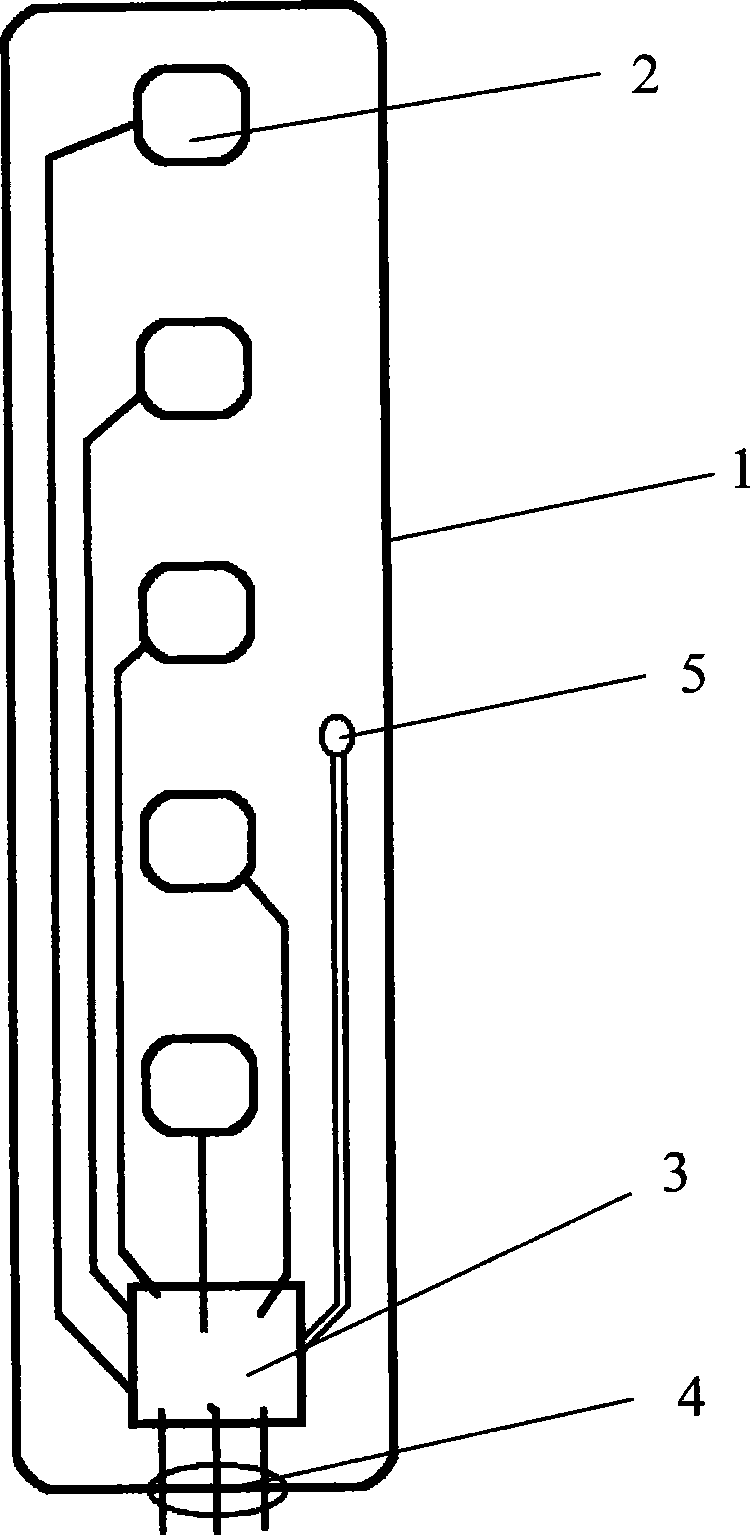

[0018] refer to figure 1 , a non-contact capacitive sensing liquid level sensor, comprising an insulating shell 1, a capacitive sensing metal part 2, a liquid level detection circuit 3 and an external signal interface 4, the insulating shell is arranged vertically, and the capacitive sensing metal part is vertically arranged Arranged in the casing, the liquid level detection circuit is installed in the casing, the liquid level detection circuit includes: an analog input port used to connect with the capacitance sensing metal part; used to detect the capacitance value of the analog input port, and The liquid level measurement module obtains the current liquid level value according to the preset corresponding relationship between the capacitance value and the liquid level, and the capacitance sensing metal part is connected to the analog input port.

[0019] The capacitive sensing metal part is copper-clad 2, and no less than two copper-clad 2 are sequentially arranged in the ca...

Embodiment 2

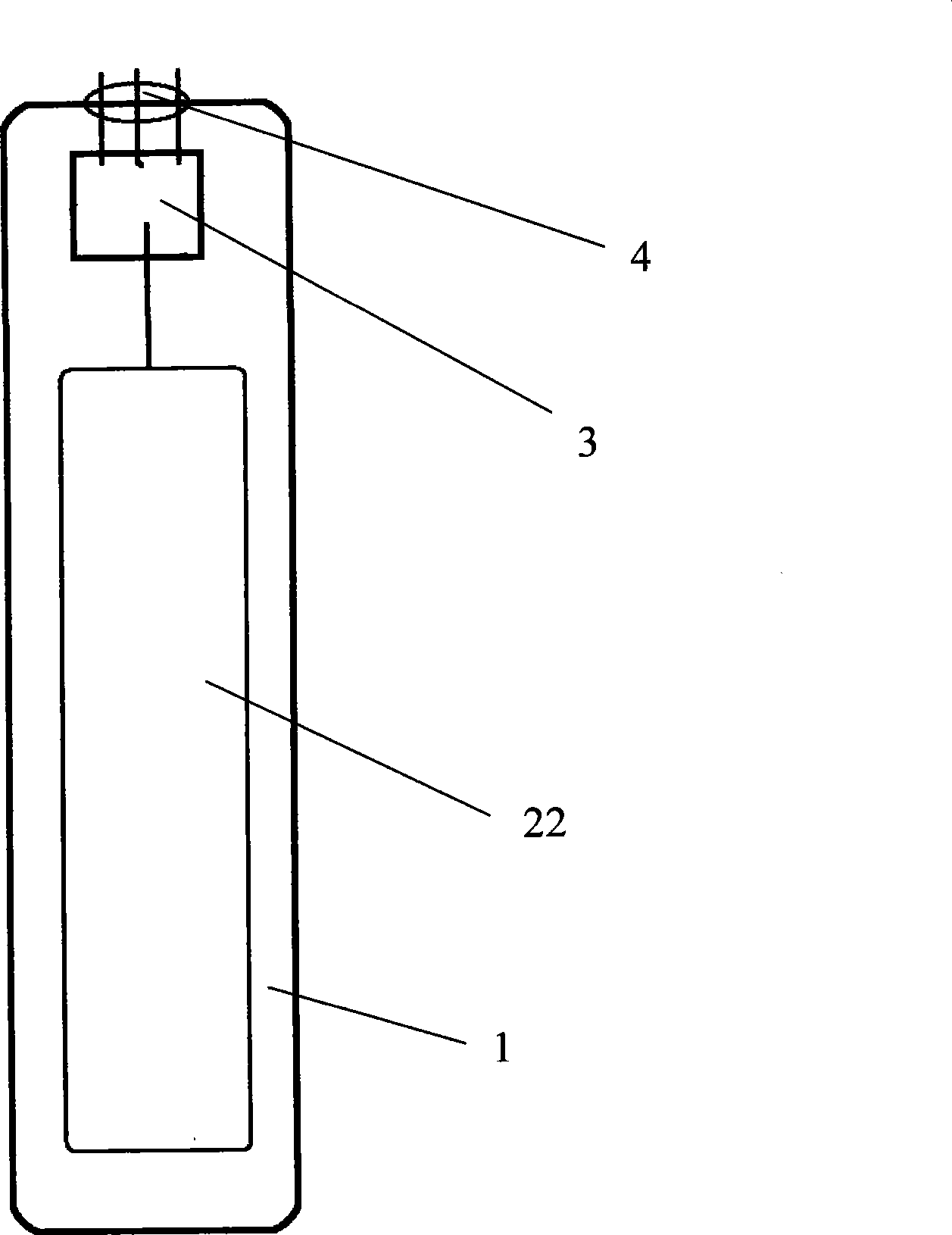

[0024] refer to figure 2 , the capacitive sensing metal part in this embodiment is the metal detection strip 22 .

[0025] The liquid submerges the insulating shell, and the difference in the coverage area submerged by the metal detection strip will lead to a change in capacitance. The change value of the capacitance is detected by the liquid level detection circuit 3 to linearly reflect the height of the liquid level and the range ratio, that is, the relationship between the capacitance value and the liquid level The corresponding relationship is a linear relationship.

[0026] The use process of this embodiment is the same as that of Embodiment 1.

[0027] This embodiment is applied in the fuel tank, and the fuel level signal is linearly and continuously transmitted to the vehicle control system through the external interface.

[0028] This embodiment can also be applied in the tank, where the liquid level signal is linearly and continuously transmitted to the external di...

Embodiment 3

[0030] The capacitive sensing metal part in this embodiment is an induction spring.

[0031] The liquid floods the insulating shell, causing the capacitance of the induction spring in the insulating shell to change, and the change value of the capacitance is detected by the liquid level detection circuit 3 to accurately reflect the state of the liquid level at the detected point or the range ratio.

[0032] The use of the spring keeps the capacitive sensing metal part in close contact with the inner wall of the insulating shell, which improves the sensitivity of liquid level detection, and is especially suitable for insulating shells with larger diameters.

[0033] The use process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com