Forming fabric and/or tissue molding belt and/or molding belt for use on an ATMOS system

A fabric and belt press technology, which is used in the field of forming fabrics, molded belts, and forming fabrics for manufacturing cotton paper and towel material, can solve the problems of marking paper webs, and achieve the effect of long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] The particulars shown herein are given by way of example only, for purposes of illustrative discussion only of embodiments of the invention, and are presented in what we believe will provide the most useful discussion of the principles and conceptual aspects of the invention. And the most understandable instructions. In this regard, only structural details of the invention are shown as necessary for a fundamental understanding of the invention, and the description in conjunction with the accompanying drawings will make clear to those skilled in the art how the forms of the invention may be embodied in practice.

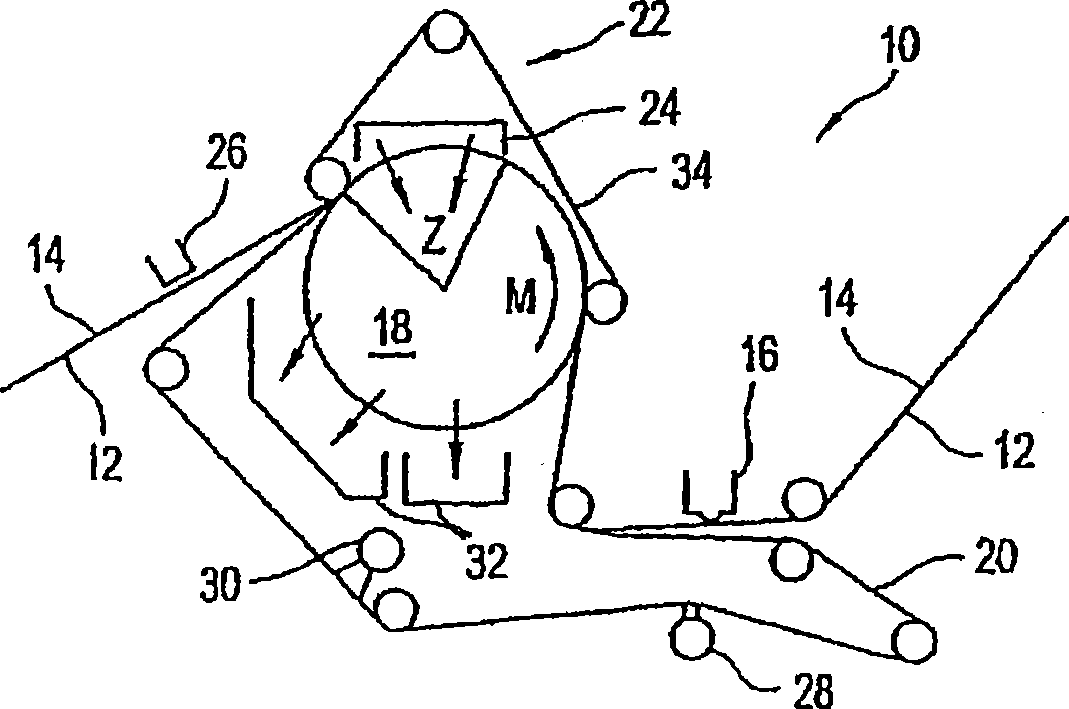

[0119] Referring now to the accompanying drawings, and more specifically to the figure 1 , which shows an advanced dewatering system 10 for processing a fibrous web 12 . System 10 includes fabric 14, suction box 16, vacuum roll 18, dewatering fabric 20, belt press assembly 22, hood 24 (which may be a hot air hood), pick-up suction box 26, Uhle box 28, one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com