Blanket machine

A punching machine and punching knife technology, which is applied to devices for cutting by nibbling, shearing devices, devices for shearing and forming blanks, etc. and other problems, to achieve the effect of improving the quality of shearing section, improving the precision of punching, and improving the efficiency of punching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

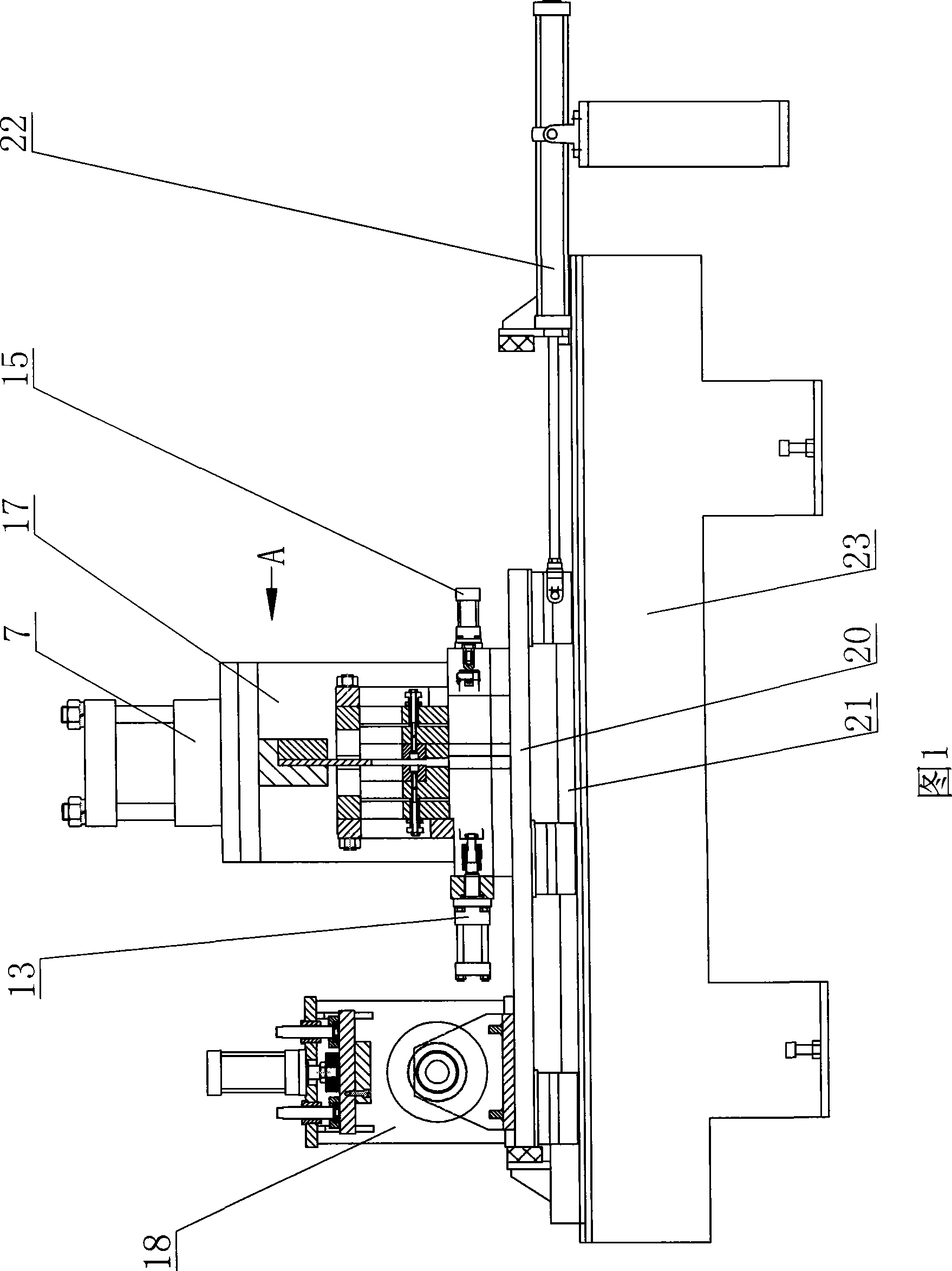

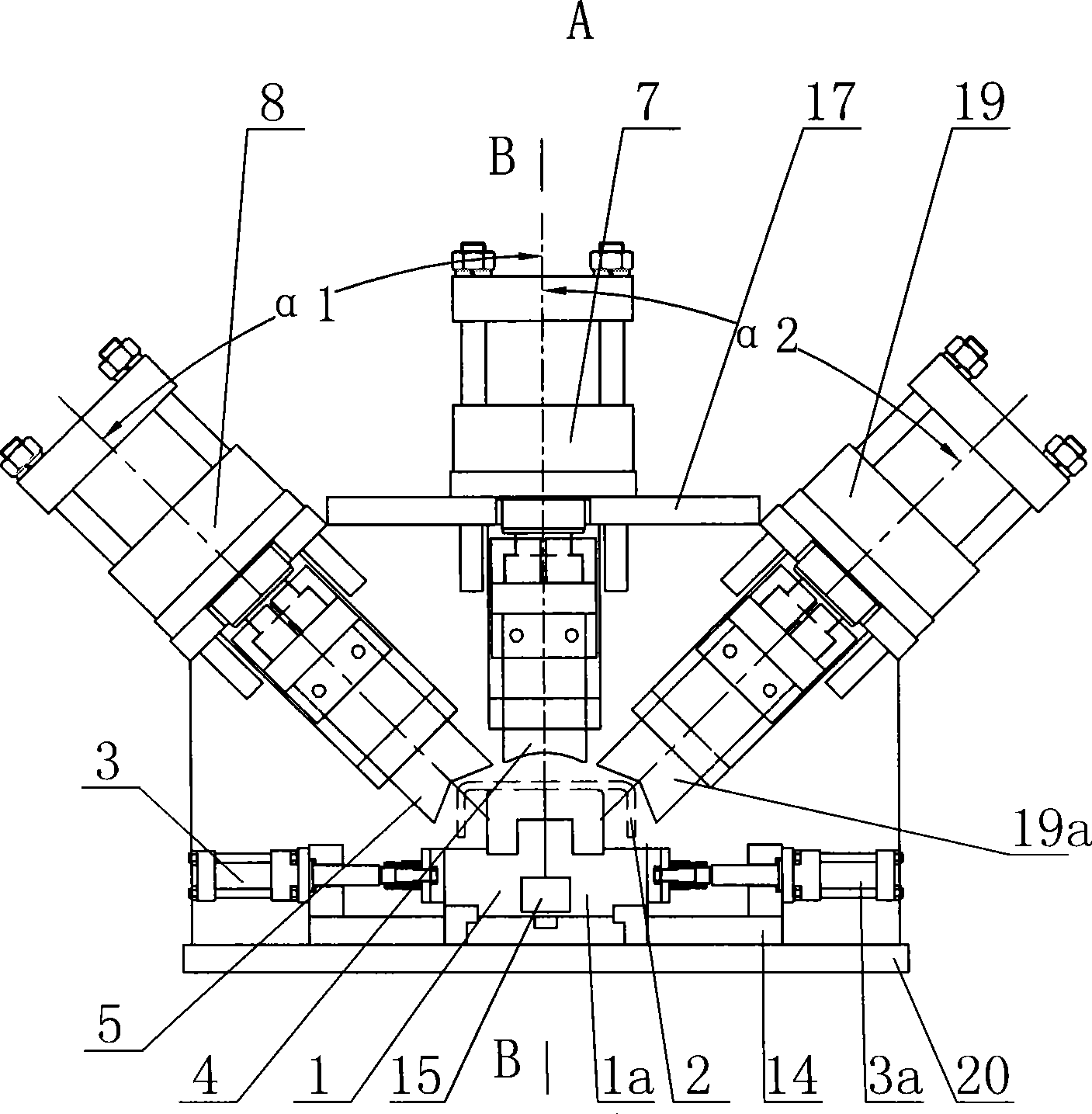

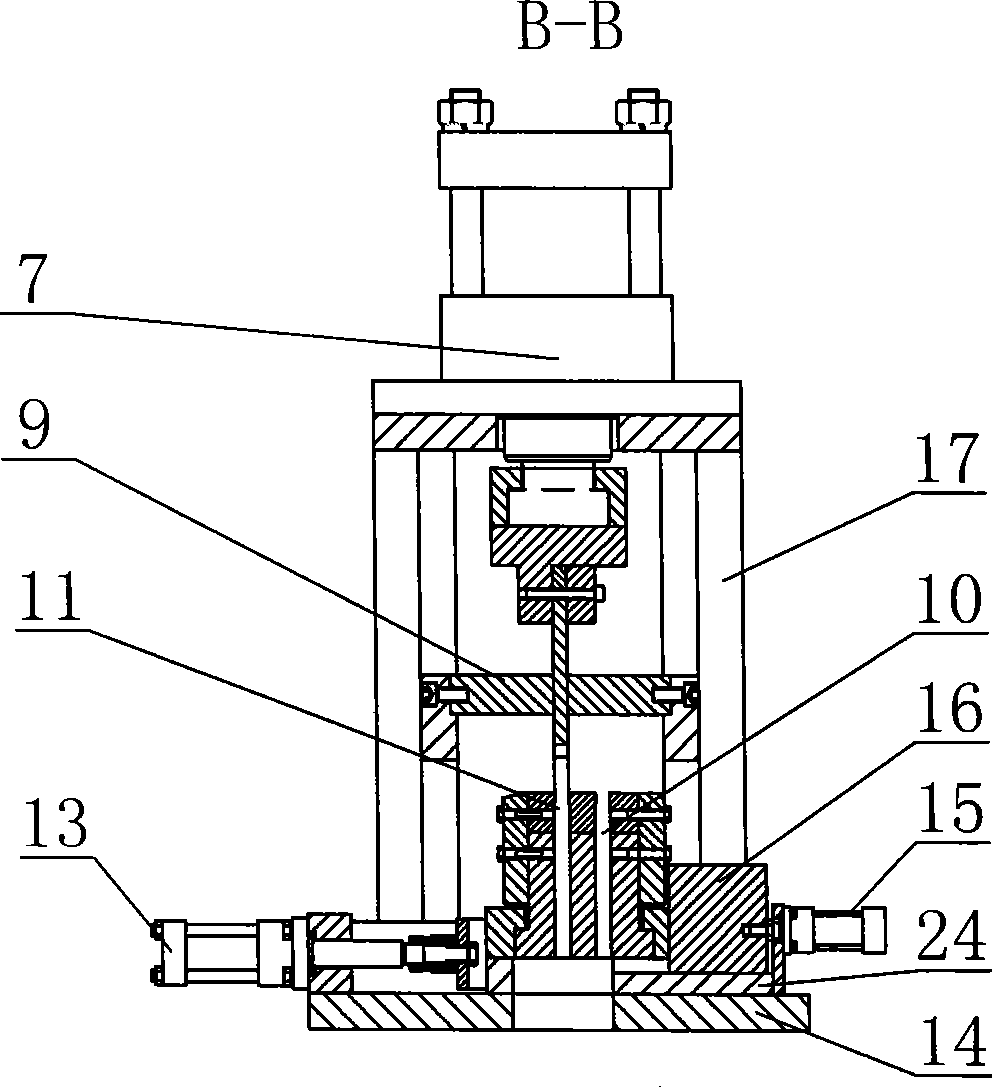

[0011] The main structure of the present invention has a machine tool 23. The machine tool 23 is equipped with a clamping device 18, a tool holder and a frame 17, a vertical punching hydraulic cylinder 7 is installed on the frame 17, and a first punching knife is installed at the lower end of the vertical punching hydraulic cylinder 7 4. The first oblique punching hydraulic cylinder 8 and the second oblique punching hydraulic cylinder 19, the first oblique punching hydraulic cylinder 8 and the second oblique punching hydraulic cylinder are respectively installed on both sides of the vertical punching hydraulic cylinder 7. The second punching knife 5 and the third punching knife 19a are respectively installed at the lower end of 19, the knife seat is located on the lower side of the first punching knife 4, and a knife groove is opened on the knife seat. The first punching knife 4, the second punching knife 5, and the third punching knife 19a are respectively directed to the knife s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com