Cutting tip

A technology of cutting inserts and cutting devices, applied in the field of cutting inserts, can solve the problems of difficulty in making cutting inserts, the optimal particle size and optimal mixing amount of resin particles are not clear, and achieve a good cutting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

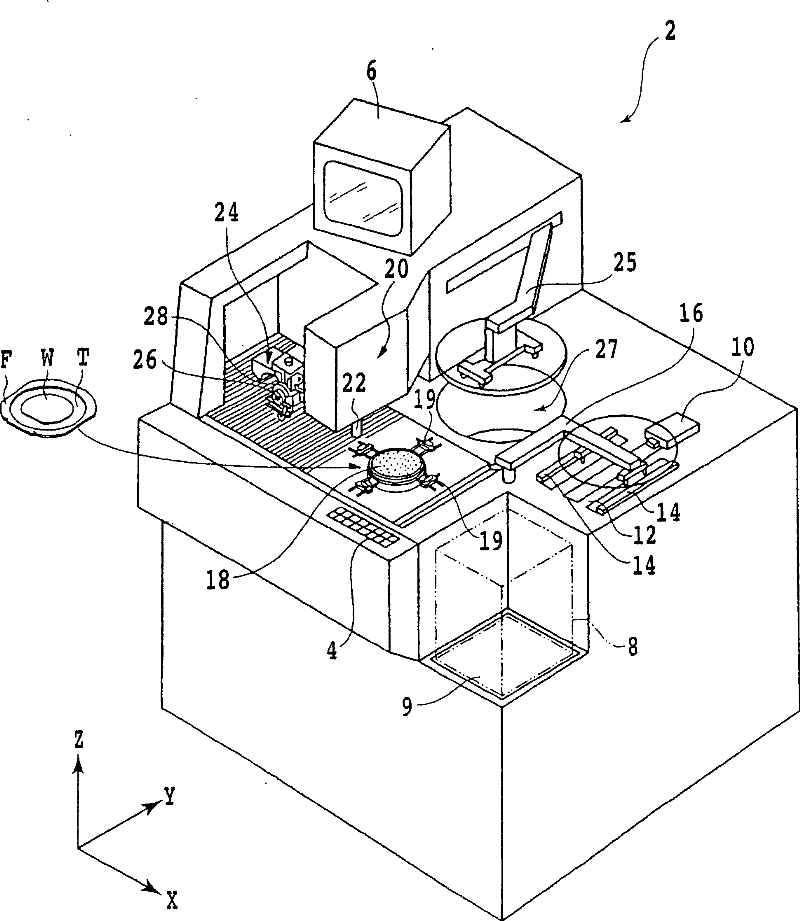

[0025] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 The appearance of a dicing device (cutting device) 2 suitable for mounting the cutting blade of the present invention is shown, which can cut a ceramic wafer or the like of a difficult-to-cut material to be divided into individual chips (devices).

[0026] On the front surface side of the cutting device 2, an operating member 4 for allowing an operator to input instructions to the device such as machining conditions is provided. A display unit 6 such as a CRT is provided on the upper part of the device, and the display unit 6 displays a guidance screen for an operator and an image captured by an imaging unit described later.

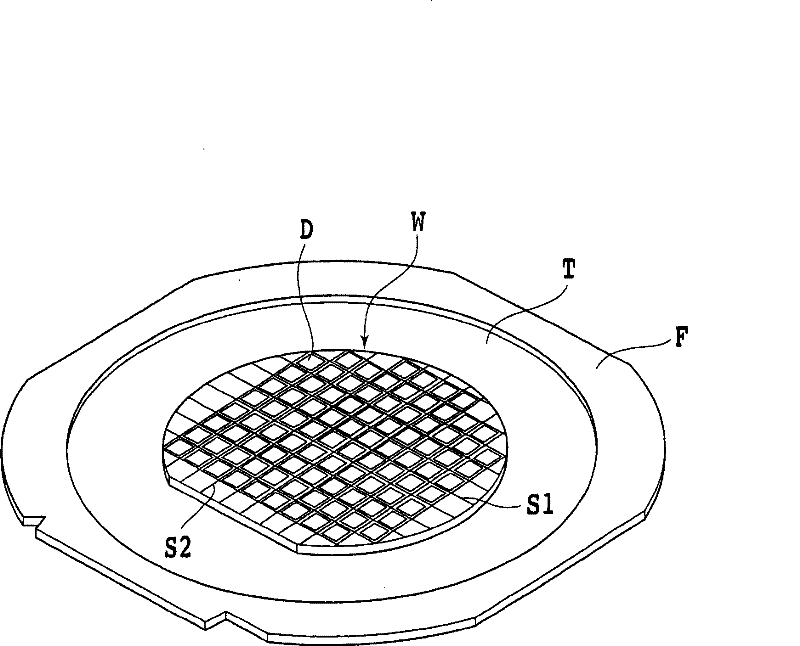

[0027] Such as figure 2 As shown, on the surface of the wafer W as the object of cutting, the first partition S1 and the second partition S2 are formed orthogonally, and the wafer W is divided by the first partition S1 and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com