Uranium well air pumping dredge method

A technology for well gas and plug removal, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problems of short validity period of well flushing and plug removal, high production cost, removal of gas and mechanical impurities, etc. The effect of uranium mining production cost and improving production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

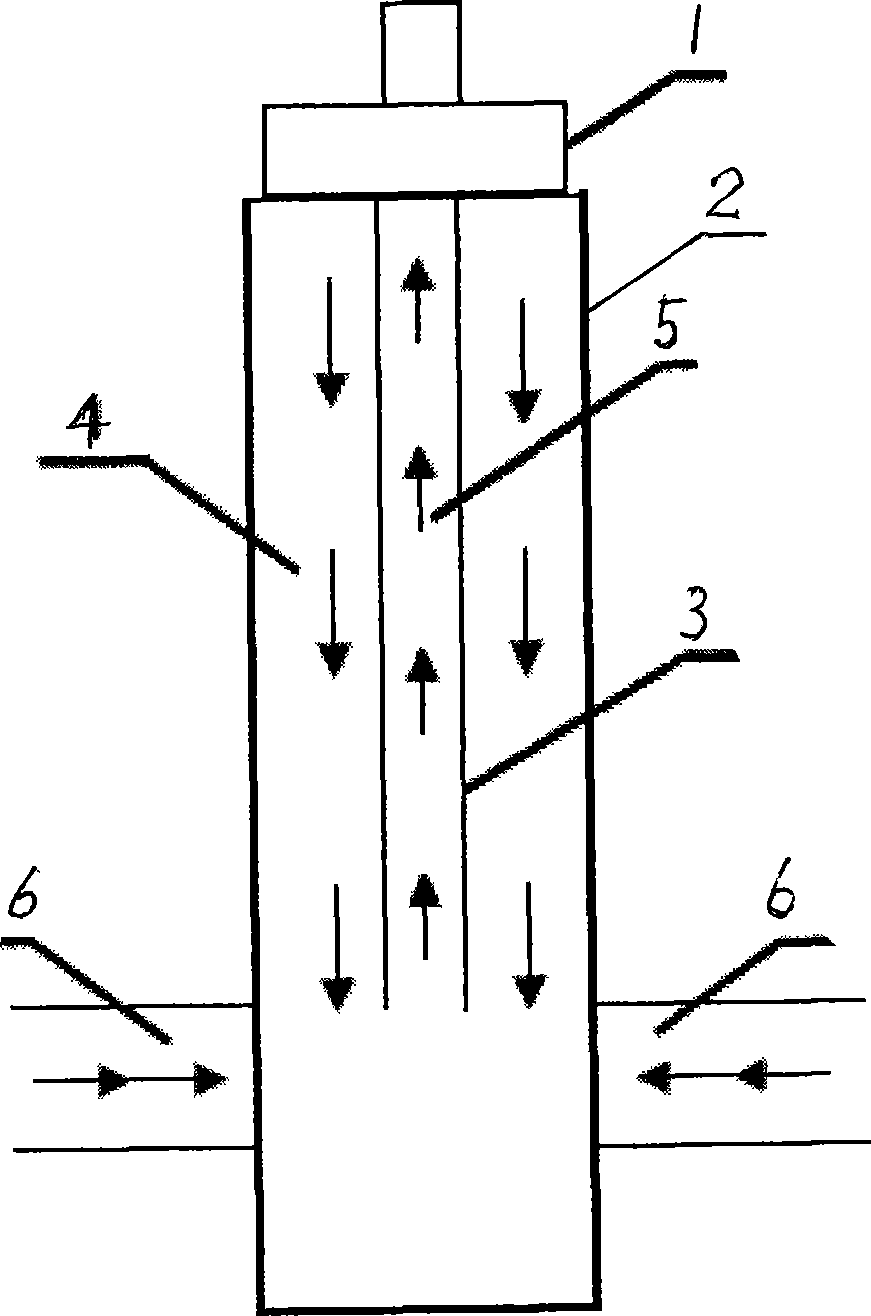

[0007] The technological process and downhole pipe string implemented by the present invention are shown in the figure. Among them, the label "1" is the wellhead device of the uranium well, the label "2" is the PVC casing, the label "3" is the polyethylene pipe with a diameter of Φ42mm, the label "4" is the high-pressure gas injected from the annular space, and the label "5" is the The return fluid extracted from the polyethylene pipe, the label "6" is the fluid entering the well in the mine bed.

[0008] The invention has been successfully applied for 42 times in the test of uranium mining by leaching without reagents in a certain block of uranium deposits, all of which have obtained good results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com