Backlight source of liquid crystal display

A liquid crystal display and backlight technology, which is applied to instruments, optics, light guides, etc., can solve problems such as affecting the overall thickness of the module, and achieve the effects of convenient assembly, reducing the width of the forehead and improving the utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

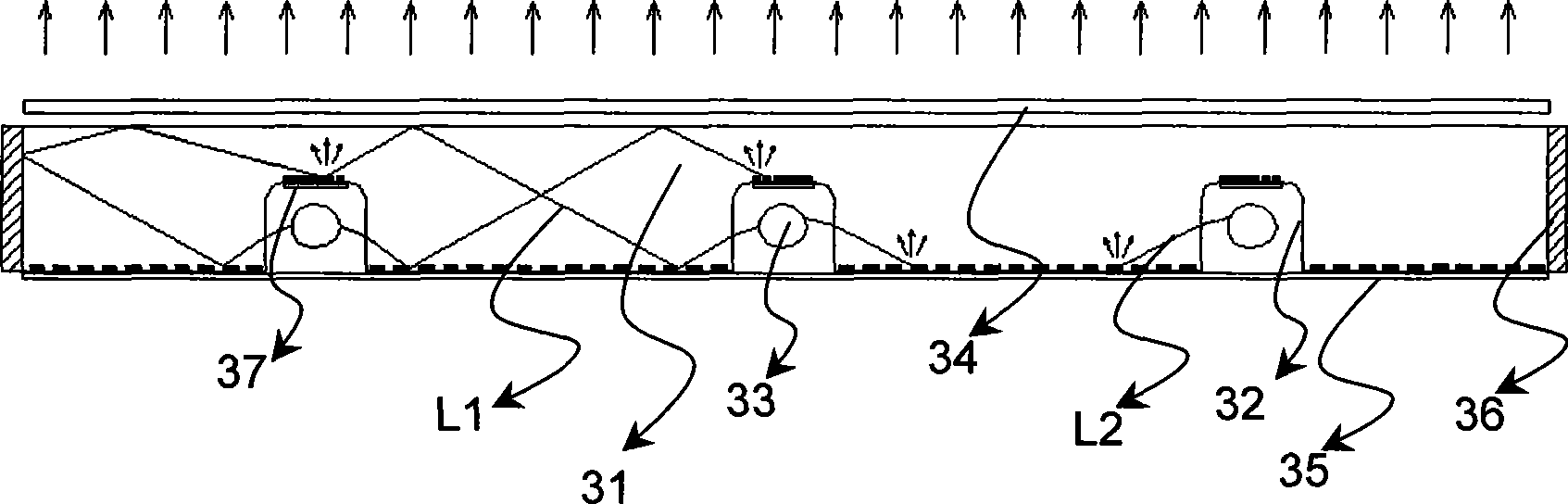

[0020] image 3 Shown is a cross-sectional view of the first backlight model of the present invention. The structure of this model is composed of a light guide plate 31, a light source 33, a reflection film 35, a side reflection film 36 and a diffusion film 34, etc. The light guide plate 31 is a specially formed light guide plate, the light source 33 is placed in the notch 32 , and side reflective films 36 are attached to both sides of the light guide plate 31 . According to the brightness requirement, select the number of light sources and the corresponding number of slots of the light guide plate. In order to prevent bright lines from appearing in the area directly above the light source 33, a notch reflective film 37 is attached to the groove on the notch 32 for light-shielding treatment. The reflective pattern of the light guide plate 31 is disposed on the bottom surface of the light guide plate 31 and the bottom surface of the notch 32 . The light L2 enters the light g...

Embodiment 2

[0025] Image 6 Shown is a cross-sectional view of another backlight model of the present invention. This model combines the structural features of the edge-type backlight and the direct-type backlight. The structure of this model is composed of a light guide plate 31, a light source 33, a reflection film 35, a light source reflection cover 66 and a diffusion film 34, etc. The light guide plate 31 is a specially formed light guide plate, a part of the light source 33 is placed in the notch 32 , and light tubes as the light source 33 are installed on both sides of the light guide plate 31 . According to the requirement of brightness, the number of light sources 33 and the number of corresponding slots of the light guide plate are selected. In order to prevent bright lines from appearing in the area directly above the light source 33, a notch reflective film 37 is attached to the groove on the notch 32 for light-shielding treatment. The reflective pattern of the light guide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com