Enclosed heat radiation system of industry control computer

A heat dissipation system and industrial control technology, applied in computing, instruments, electrical digital data processing, etc., can solve the problems of multiple heat conduction links, serious heat conduction loss, and large thermal resistance, so as to reduce intermediate links, ensure safe use, and improve heat conduction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

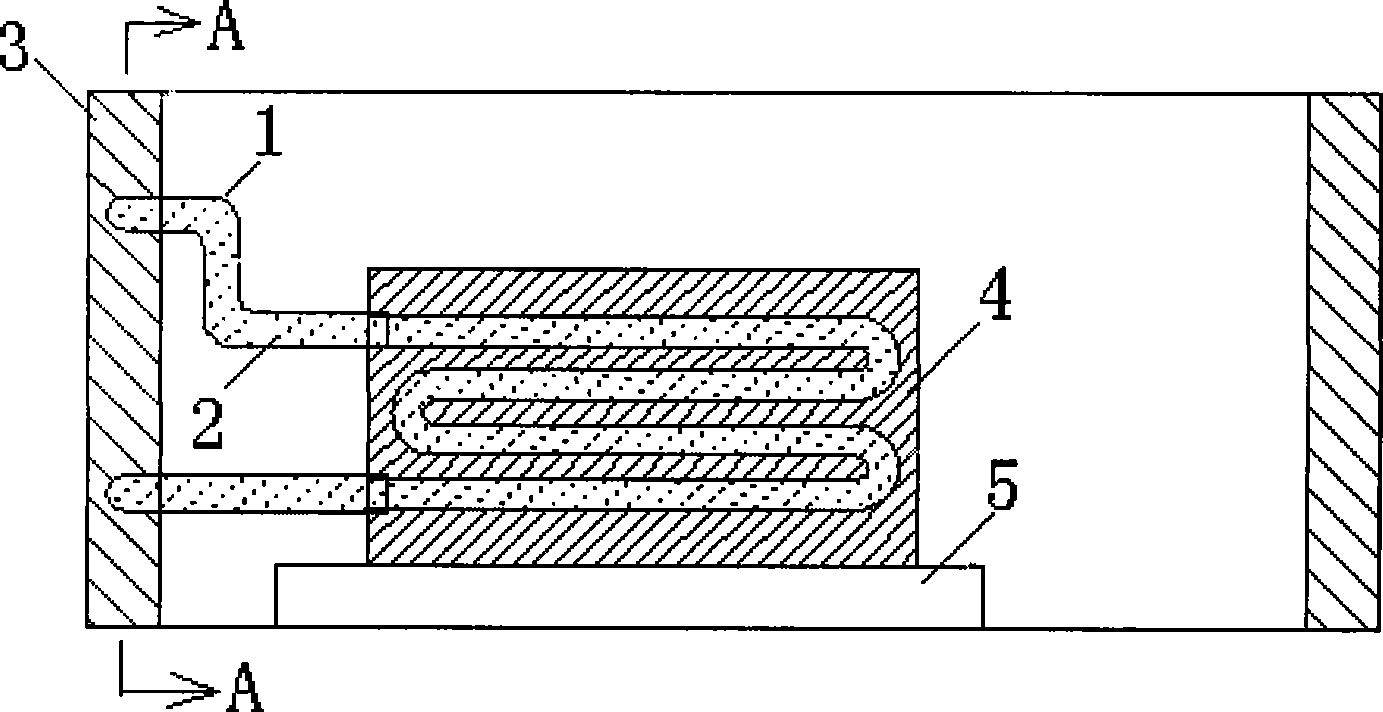

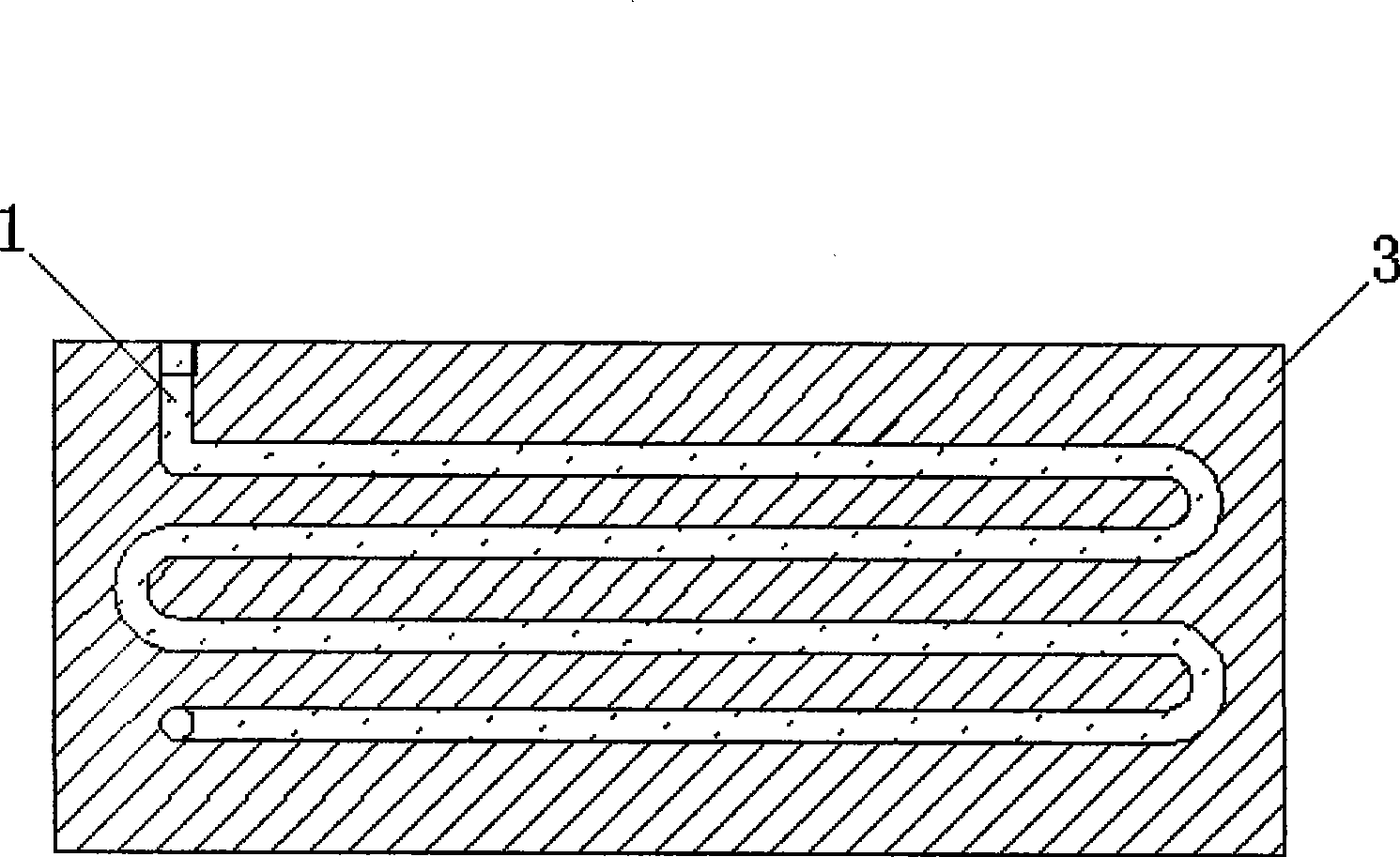

[0014] see figure 1 , a heat dissipation system of a closed industrial control computer of the present invention is composed of a radiator 4, a heat transfer tube 1, a heat transfer fluid 2, and a computer case shell 3. The pipeline in the radiator 4 communicates with the heat transfer tube 1, and the thermal transfer fluid 2 In the pipes of the radiator 4 and the heat pipe 1, the heat pipe 1 sandwiched in the computer case shell 3 is a pipe bent several times.

[0015] When the present invention is used, the heat pipe 1 in the computer case shell 3 is connected with the heating device 5 of the computer through the radiator 4 . After the computer starts to work, the heat of the heating device 5 of the computer is transmitted to the outer surface of the computer case shell 3 through the thermal fluid 2, so that the heat of the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com