Method for improving meat quality

A technology for meat quality and beef, applied in the field of improving meat quality, can solve problems such as affecting the processing performance of beef and the acceptance of beef and its products, limiting beef production and consumption, and being difficult to chew, etc., to reduce losses, overcome transitional losses, and retain water. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A method for improving meat quality, comprising the following steps:

[0015] (1) Raw material processing: Remove the tendons from the fresh beef, cut the fat along the muscle fiber direction, and cut into 100g. The specifications are 6-7cm in length, 4-5cm in width, and 2-3cm in thickness.

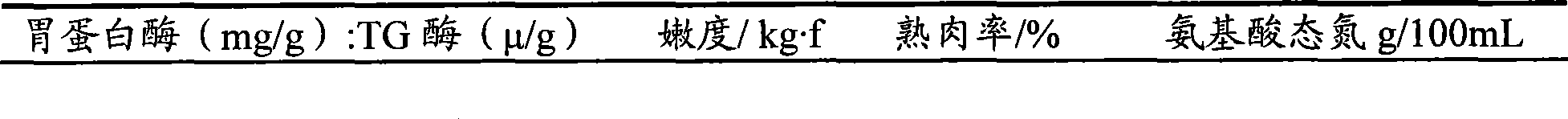

[0016] (2) Pepsin tenderization: absorb 0.6mg / g pepsin (600mg of pepsin to 50mL) 5mL with a syringe, inject in different parts of the meat, try to make it evenly distributed in every part of the meat, and then Roll and knead for 10 minutes, keep warm at 40°C for 10 minutes, so that the enzyme can fully react. The purpose is to make the enzyme fully act on the meat to achieve the desired tenderizing effect.

[0017] (3) TG enzyme cross-linking: use a syringe to absorb 4.2mL of TG enzyme solution (weigh 7g of TG enzyme, and make it to 50mL), and inject it in different parts of the meat. 0.75%. Then roll and knead for 20 minutes to promote the TG enzyme to penetrate evenly, and kee...

Embodiment 2

[0023] (1) Raw material processing: remove the tendons from the cold-processed beef, cut the fat along the muscle fiber direction, and cut into 100g. The specifications are 6-7cm in length, 4-5cm in width, and 2-3cm in thickness.

[0024] (2) Pepsin tenderization: use a syringe to draw 5mL of pepsin solution 0.6mg / g (take 600mg of pepsin and dilute it to 50mL), inject it in different parts of the meat, and try to make it evenly distributed in every part of the meat, Roll and knead for 10 minutes, and keep warm at 40°C for 10 minutes to fully react the enzyme.

[0025] (3) TG enzyme cross-linking: use a syringe to absorb 4.2mL of TG enzyme solution (weigh 7g of TG enzyme, and make it to 50mL), and inject it in different parts of the meat. 0.75%. Roll and knead for 10 minutes, and keep warm at 40°C for 90 minutes, so that the enzyme can be fully used in the meat and fully reacted.

[0026]The control raw beef sample and the enzyme-treated sample were mashed by a tissue grinder...

Embodiment 3

[0028] (1) Raw material processing: Remove the tendons from the fresh beef, cut the fat along the muscle fiber direction, and cut into 100g. The specifications are 6-7cm in length, 4-5cm in width, and 2-3cm in thickness.

[0029] (2) Pepsin tenderization: use a syringe to draw 5mL of pepsin solution 0.6mg / g (take 600mg of pepsin and dilute it to 50mL), inject it in different parts of the meat, and try to make it evenly distributed in every part of the meat, Tumble and knead at room temperature for 20 minutes, and keep warm at 40°C for 10 minutes to fully react the enzyme.

[0030] (3) TG enzyme cross-linking: use a syringe to absorb 4.2mL of TG enzyme solution (weigh 7g of TG enzyme, and make it to 50mL), and inject it in different parts of the meat. 0.75%. Carry out tumbling at room temperature for 10 minutes, and keep warm at 40°C for 180 minutes, so that the enzyme can be fully used in the meat and fully reacted.

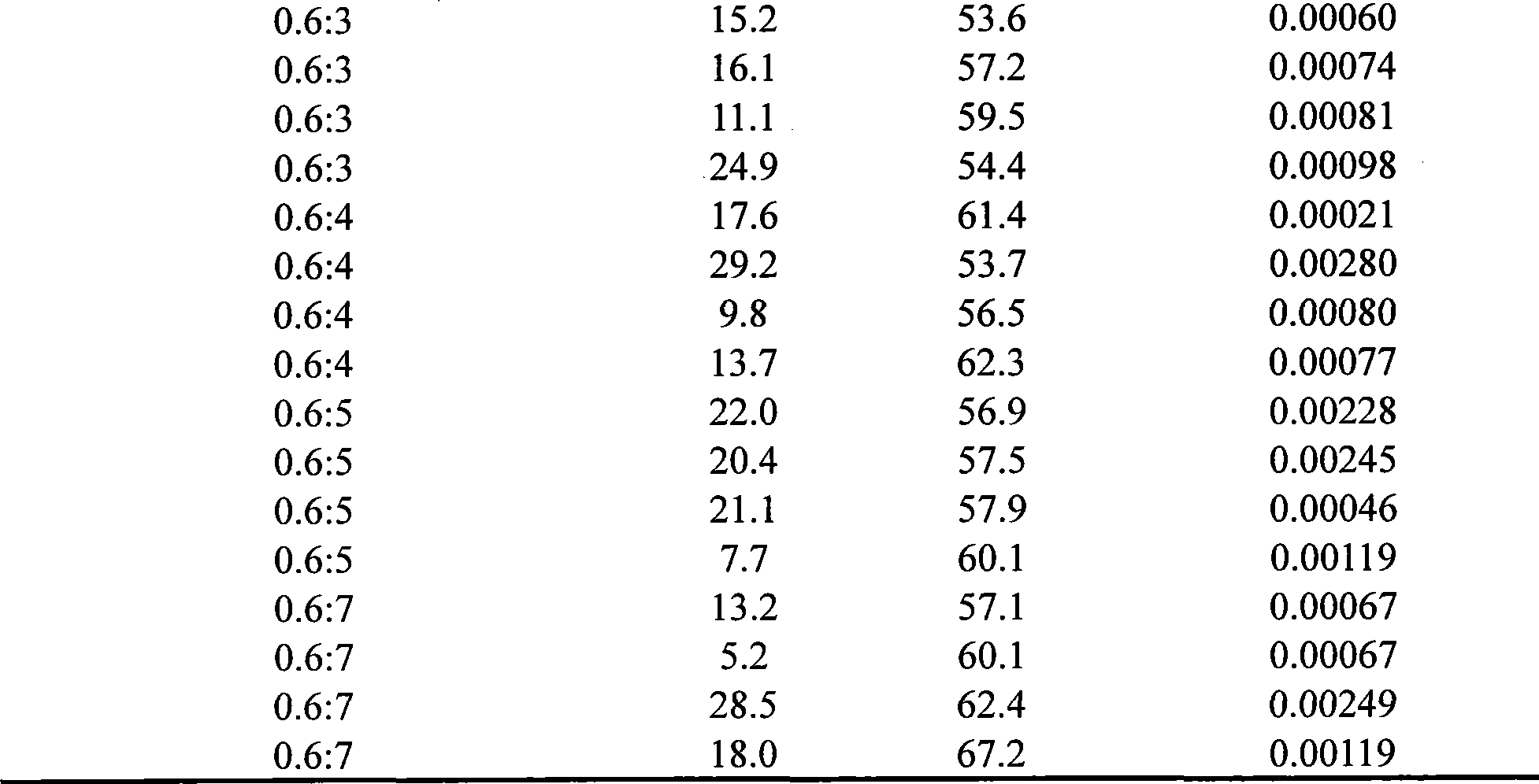

[0031] (4) Heat and cook the enzyme-treated beef for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com