Counter-pressure casting process for casting parts of door cover

A technology of differential pressure casting and casting process, which is applied in the field of differential pressure casting process of hatch cover castings, which can solve problems such as difficulty in casting forming, unqualified casting pressure test, great difference in wall thickness, etc., and achieve service life and reliability The effects of improving, reducing microstructure porosity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

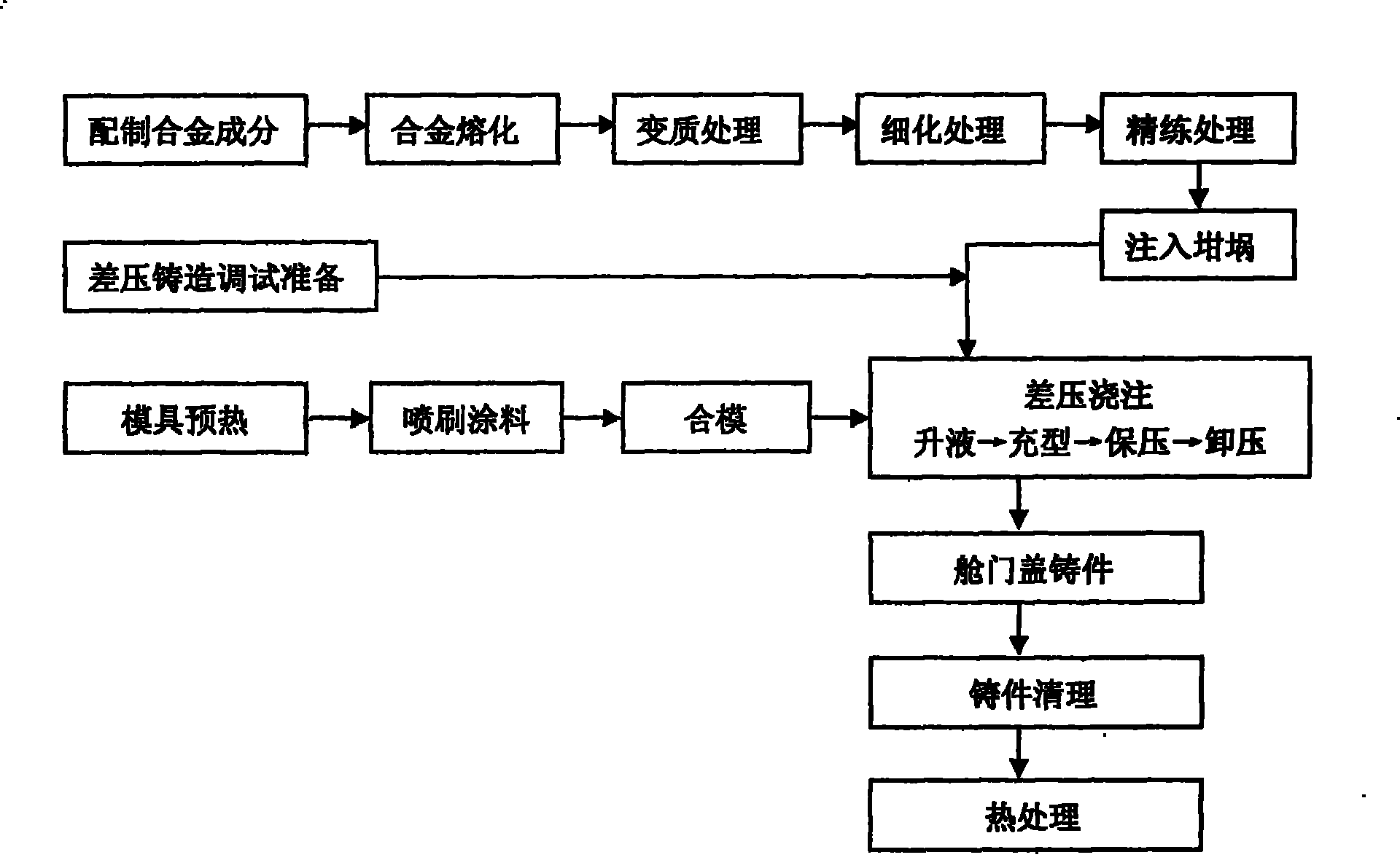

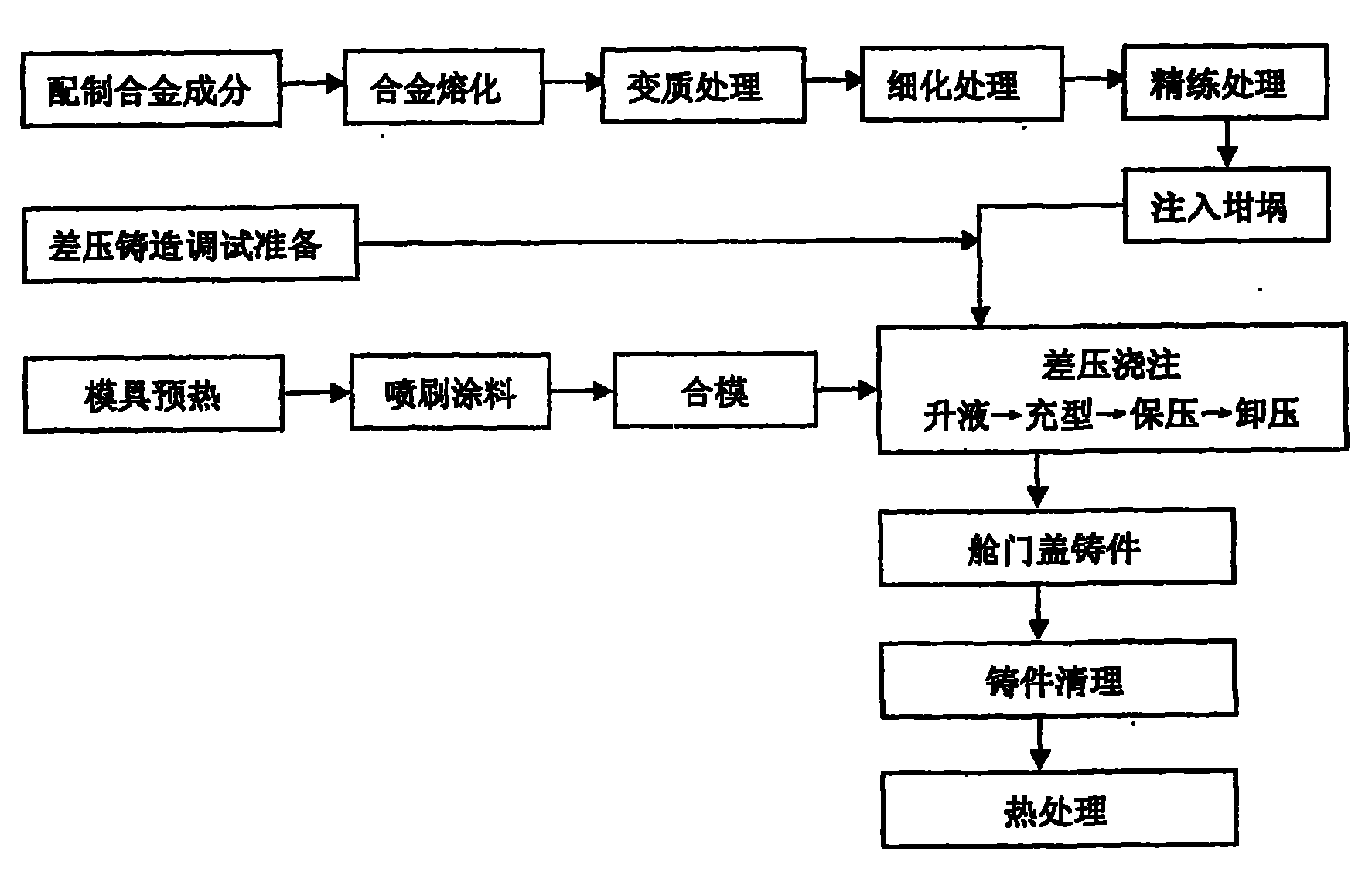

[0035] figure 1 Medium, differential pressure casting figure 2 The process steps of hatch cover casting are as follows:

[0036] 1. Prepare the ZL114A alloy composition. The chemical composition is: Si 6.5, Mg 0.45, Ti 0.1, Be0.04, Fe≤0.2, Mn≤0.1, Cr≤0.05, Pb≤0.03, Sn≤0.01, and the rest is Al ;

[0037] 2. Put the ZL114A alloy into the melting furnace for melting. After melting, the alloy solution needs to be refined and refined. The refinement treatment: the temperature is 740°C, and 0.3% of the mass percentage of aluminum titanium boron is added according to the total amount of the alloy solution. Refining agent; refining treatment: at a temperature of 730°C, add a refining agent with a mass percentage of 0.3% according to the total amount of alloy liquid, and finally inject the treated alloy liquid into a differential pressure casting insulation crucible;

[0038] 3. To prepare for commissioning of the differential pressure casting machine, install the riser pipe prehea...

Embodiment 2

[0045] 1. Prepare the ZL114A alloy composition. The chemical composition is: Si7, Mg 0.52, Ti 0.15, Be0.055, Fe≤0.2, Mn≤0.1, Cr≤0.05, Pb≤0.03, Sn≤0.01, and the rest is Al by mass percentage;

[0046]2. Put the ZL114A alloy into the melting furnace for melting. After melting, the alloy solution needs to be refined and refined. The refinement treatment: the temperature is 750 ° C, and 0.4% of the mass percentage of aluminum titanium boron is added according to the total amount of the alloy solution. Refining agent; refining treatment: at a temperature of 730°C, add a refining agent with a mass percentage of 0.4% according to the total amount of alloy liquid, and finally inject the treated alloy liquid into a differential pressure casting insulation crucible;

[0047] 3. Prepare for commissioning of the differential pressure casting machine, install the riser pipe preheated to 180°C on the holding furnace, and conduct a sealing test;

[0048] 4. Preheat the mold, preheat the mold...

Embodiment 3

[0054] 1. Prepare the ZL114A alloy composition. The chemical composition is: Si7.5, Mg 0.6, Ti 0.2, Be0.07, Fe≤0.2, Mn≤0.1, Cr≤0.05, Pb≤0.03, Sn≤0.01, and the rest are Al;

[0055] 2. Put the ZL114A alloy into the melting furnace for melting. After melting, the alloy liquid needs to be refined and refined. The refinement treatment: the temperature is 760 ° C, and 0.5% of the mass percentage of aluminum titanium boron is added according to the total amount of the alloy liquid. Refining agent; refining treatment: at a temperature of 740°C, add a refining agent with a mass percentage of 0.5% according to the total amount of alloy liquid, and finally inject the treated alloy liquid into a differential pressure casting insulation crucible;

[0056] 3. Prepare for commissioning of the differential pressure casting machine, install the liquid rising pipe preheated at 190°C on the holding furnace, and conduct a sealing test;

[0057] 4. Preheat the mold, preheat the mold to 250°C, sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com