Electrode wire for slow-travel wire spark erosion fabrication and preparation method thereof

A technology for corrosion processing and electrode wire, applied in the field of low-copper slow-moving wire electrode wire and its preparation, can solve the problems of increased production cost, expensive production equipment, complicated preparation process, etc., and achieves reduction of copper content, simple production equipment, The effect of fewer preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

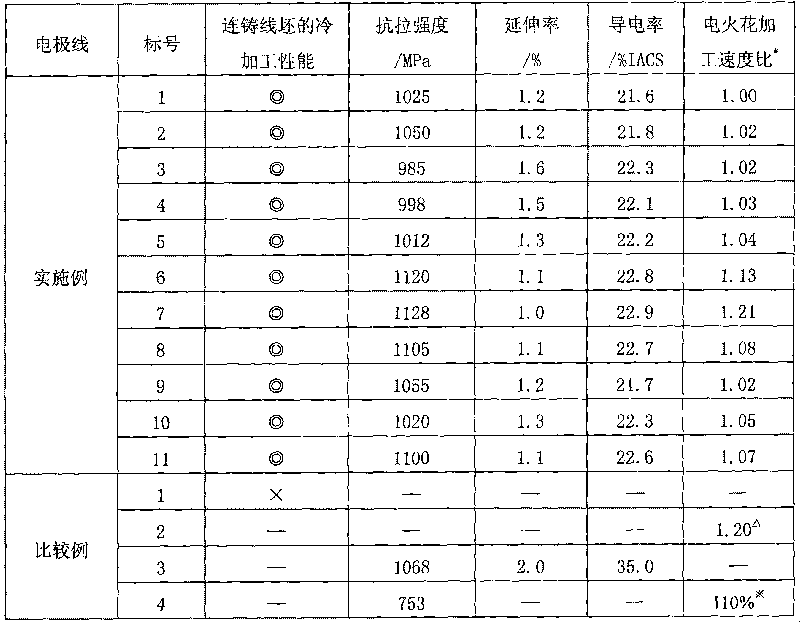

Examples

Embodiment 1

[0020] Alloys were formulated according to the following weights: Cu: 47.440 kg; Zn: 32.036 kg; Mn: 0.400 kg; Mg: 0.08 kg; La: 0.032 kg; Zr: 0.016 kg. Put the prepared mixture into a power frequency induction melting furnace to melt it, the melting temperature is 1180°C, and the holding time is 30 minutes; continuously melt three furnaces of liquid metal and introduce them into the horizontal continuous casting furnace one by one, and then use the horizontal The continuous casting method is used to prepare alloy wire blanks. The horizontal continuous casting process is as follows: set the continuous casting temperature to 1150°C, the cooling water pressure of the crystallizer during continuous casting is 0.7-0.8MPa, the cooling water inlet temperature is ≤32°C, and the temperature difference between the inlet and outlet water is 7 ~ 8 ℃, the continuous casting speed is 1500mm / min; then the wire billet is drawn and annealed online by multiple channels Annealing is carried out w...

Embodiment 2

[0023] Alloys were formulated according to the following weights: Cu: 46.799 kg; Zn: 32.596 kg; Al: 0.153 kg; Mn: 0.407 kg; La: 0.026 kg; Ce: 0.023 kg. Put the prepared mixture into a power frequency induction melting furnace to melt it, the melting temperature is 1180°C, and the holding time is 30 minutes; continuously melt three furnaces of liquid metal and introduce them into the horizontal continuous casting furnace one by one, and then use the horizontal The continuous casting method is used to prepare alloy wire blanks. The horizontal continuous casting process is as follows: set the continuous casting temperature to 1150°C, the cooling water pressure of the crystallizer during continuous casting is 0.7-0.8MPa, the cooling water inlet temperature is ≤32°C, and the temperature difference between the inlet and outlet water is 7~8℃, the continuous casting speed is 1500mm / min; then the wire blank is subjected to multi-channel stretching and online annealing (annealing tempera...

Embodiment 3

[0026]Alloys are formulated according to the following weights: Cu: 45.826 kg; Zn: 32.621 kg; Sn: 0.048 kg; Mg: 0.855 kg; Ce: 0.017 kg; Cu-B master alloy (B content is 2%): 0.640 kg. Put the prepared mixture into a power frequency induction melting furnace to melt it, the melting temperature is 1180°C, and the holding time is 30 minutes; continuously melt three furnaces of liquid metal and introduce them into the horizontal continuous casting furnace one by one, using horizontal continuous casting Methods The alloy wire blank was prepared, and the horizontal continuous casting process was as follows: the continuous casting temperature was 1150°C, the cooling water pressure of the crystallizer was 0.7-0.8MPa during continuous casting, the inlet temperature of the cooling water was ≤32°C, and the temperature difference between the inlet and outlet water was 7-8°C , the continuous casting speed is 1500mm / min; then the wire blank is subjected to multi-channel stretching and online ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com