Lamination-proof structure of laser shock processing

A technology of laser shock and protective layer, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as difficult solid support, high shock wave reflection coefficient, and poor protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described in detail below with reference to the accompanying drawings and embodiments:

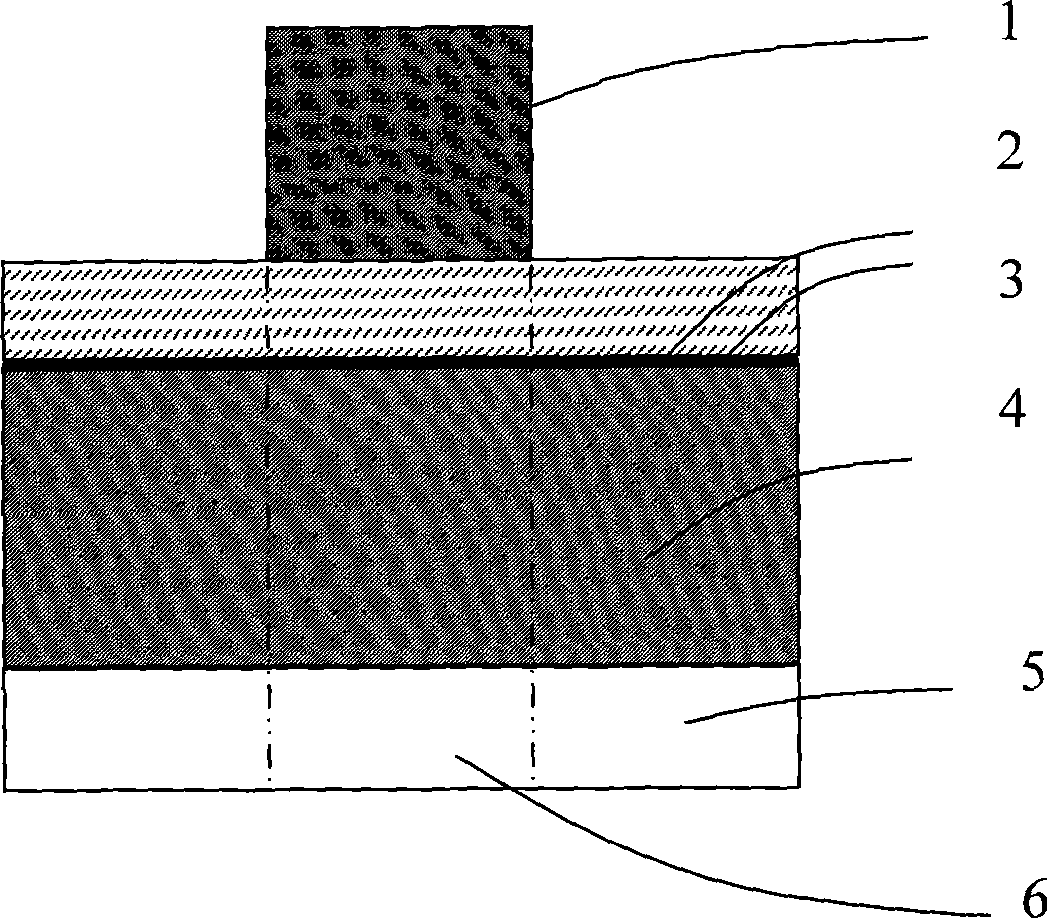

[0014] See attached figure 1 As shown in the laser shock treatment of the anti-spam structure, the material of the metal target 4 is titanium alloy, aluminum alloy or stainless steel, and it is characterized in that: the back of the metal target 4 is covered with a layer of the metal target 4 material Protective layer 5 made of materials with close acoustic resistance, single-layer or multi-layer aluminum foil tape with a thickness of 0.2mm~0.5mm;

[0015] When the absorbing layer of the reflective area 6 is peeled off and overlaps with the next strengthening area by 50%, the absorbing layer needs to be replaced.

[0016] When laser shock processing metal materials, the laser 1 passes through the confinement layer 2 and reaches the absorption layer 3 and then generates a shock wave, which is directed to the metal target 4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com