Zirconium based amorphous alloy and manufacture method thereof

A technology of zirconium-based amorphous alloy and amorphous alloy, which is applied in the field of zirconium-based amorphous alloy and its preparation, can solve the problem of low bending strength of zirconium-based amorphous alloy, increased production cost of zirconium-based amorphous alloy products, and amorphous alloy. Low content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

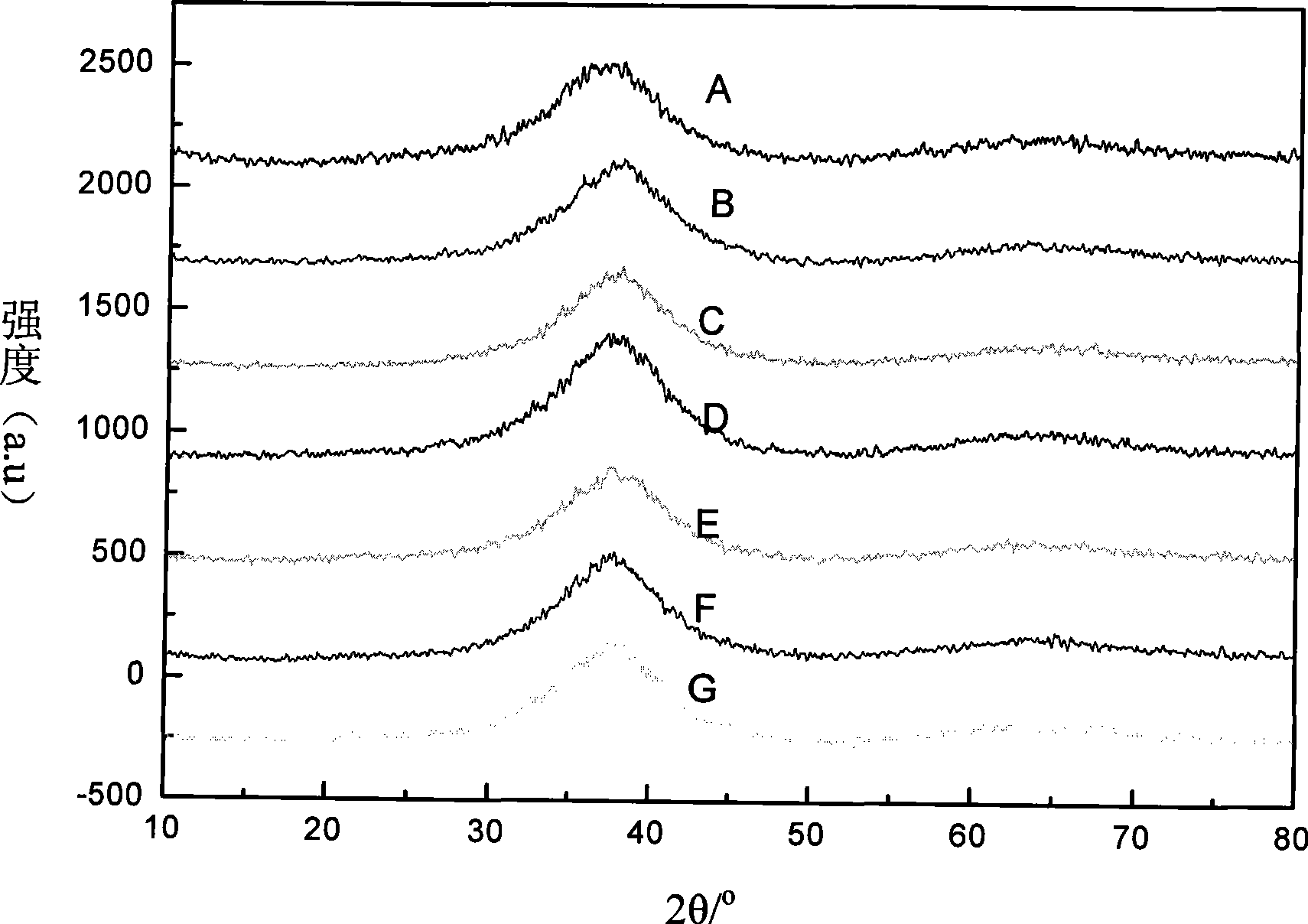

Image

Examples

preparation example Construction

[0017] The preparation method of the rare earth-based amorphous alloy provided by the present invention is simple, the process is easy for continuous production, and the cooling rate is 10-10 5 K / s, absolute pressure of vacuum environment 10 -2 Under the condition of -100 Pa, a zirconium-based amorphous alloy with an amorphous content of more than 80% by volume can be obtained. Through the method, the obtained zirconium-based amorphous alloy has good flexural and impact resistance.

[0018] The present invention provides a method for preparing a zirconium-based amorphous alloy. The method includes smelting and cooling the amorphous alloy raw materials under protective gas, wherein the amorphous alloy raw materials include: Zr, T M , Ti and Be, Zr, T M , Ti and Be added to make the resulting alloy composition: Zr a T Mb Ti c Be d , Where 20≤a≤75, 10≤b≤50, 1≤c≤30, 10≤d≤40, a, b, c, d are mole percentages and a+b+c+d=100; preferably , 40≤a≤46, 22≤b≤27, 1≤c≤11, 20≤d≤25, and a+b+c+d=10...

Embodiment 1

[0024] This embodiment is used to illustrate the preparation method of the zirconium-based amorphous alloy provided by the present invention.

[0025]Put 22 grams of amorphous alloy raw materials into the electric arc furnace (Shenyang Scientific Instrument Manufacturing Co., Ltd.), and evacuate the electric arc furnace, where the vacuum degree is 5 Pa. Using argon with a purity of 99.0% by volume as the protective gas, smelting at 1800°C for 20 seconds. The composition of the amorphous alloy is 42% Zr, 9% Ti, 14% Cu, 12% Ni, and 23% Be.

[0026] Then cast the molten alloy sample into a copper mold to 10 5 Air cooling is carried out at a cooling rate of K / s, and the alloy sample D with a size of 100mm×10mm×3mm is cast. 1 , The composition of the alloy sample is Zr 42 Ti 9 Cu 14 Ni 12 Be 23 .

Embodiment 2

[0028] This example illustrates the preparation method of the zirconium-based amorphous alloy provided by the present invention.

[0029] Put 22 grams of amorphous alloy raw materials into an electric arc furnace (Shenyang Scientific Instrument Manufacturing Co., Ltd.), and evacuate the electric arc furnace, where the vacuum degree is 50 Pa. Using argon with a purity of 99.2% by volume as the protective gas, smelting at 2000°C for 24s. The composition of the amorphous alloy is 40% Zr, 11% Ti, 14% Cu, 11% Ni, and 24% Be.

[0030] Then the molten alloy sample was cast into a copper mold and air-cooled at a cooling rate of 10K / s, and cast into an alloy sample D with a size of 100mm×10mm×3mm 2 , The composition of the alloy sample is Zr 40 Ti 11 Cu 14 Ni 11 Be 24 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com